Emissions Control

Point Source Capture Home | Capture from Power Generation Sources | Capture from Industrial Sources

The U.S. Department of Energy’s (DOE) Emissions Control Program develops technological improvements and solutions for control of non-CO2 emissions (liquids, gases, and solids) associated with carbon capture, plus management, disposition, and remediation of coal combustion residuals (CCRs) and CCR storage sites. The next-generation concepts and advanced technologies that the National Energy Technology Laboratory (NETL) and partners are working on are intended to address the urgent need to safely manage and disposition aging inactive/legacy CCR impoundments, control emissions associated with those impoundments, and control non-CO2 emissions that may occur with more widespread implementation of carbon capture and decarbonization. These technological advancements will help foster environmental justice as they underpin remediation of legacy harms of fossil fuel use, reduction of the volume of CCRs for disposal, and address any pollution issues that might emerge in the large-scale implementation of carbon capture.

Although prior research and development (R&D) on coal combustion byproducts was carried out in the 1990s and through 2008 via DOE’s Innovations for Existing Plants Program, the U.S. Environmental Protection Agency (EPA) rule published in 2015 provided new impetus for attention to this issue. Also, the DOE Office of Fossil Energy and Carbon Management’s (FECM) current mandates, including point source carbon reductions and justice principles, are strongly driving the work under this program:

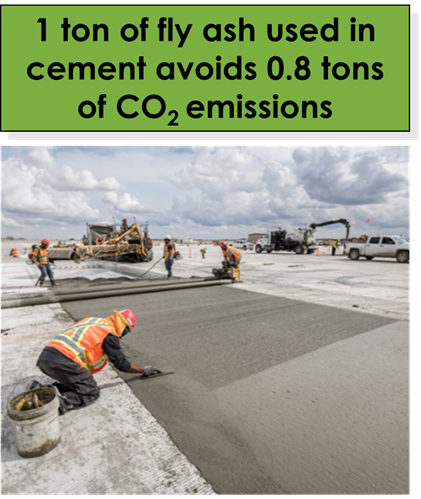

- Carbon dioxide (CO2) Reductions—Reuse of CCRs not only accrues financial revenue for plant operators and CCR marketers, but it yields important environmental benefits as well. For example, for each ton of fly ash used to replace Portland cement in concrete, nearly one ton of CO2 emissions is avoided.

- Control of Non-CO2 Emissions in the Decarbonized Economy—DOE/NETL have made a large ongoing investment in advanced technologies for efficient and low-cost point source CO2 capture. As those advanced technologies come online and are applied on a large scale, it will be important to understand and manage any resultant derivative emissions. It is known that conventional solvent-based capture using amine solvents may have complex effects on multiple pollutant species emissions tendencies, and that solvent degradation may result in emissions of species of concern such as ammonia. These kinds of effects demand careful attention in readying technology for capture implementation and capture retrofits.

- Environmental Justice—Beneficial reuse means less landfill space is needed to dispose of bulky CCR materials.

- Other Justice—FECM strives to incorporate justice principles with community participation, just distribution of benefits, and emphasis on remediating legacy harms while also mitigating new impacts. Initiatives to increase beneficial use of CCRs and managing CCR impoundments can strongly promote justice by opportunity to site beneficial use facilities in economically struggling communities, and to address environmental liabilities and impacts of legacy ash impoundments near those communities.

Emission Control Program R&D Focus Areas

- Innovative technology and concepts to increase beneficial utilization—focus on the fraction of coal combustion products that are not currently being recycled or beneficially reused at high levels, such as non-gypsum, wet- and dry-flue gas desulfurization (FGD) materials and bottom ash, and materials used in current CCR facilities that may be negatively impacted by new CCR regulations. NETL seeks to understand technical, cost, and logistical barriers to increasing the use of these CCR materials, and how technology-based solutions would overcome these barriers.

- Innovations for improved cost and performance of CCR beneficiation/upgrading technologies—focus on improvements in the performance and cost of beneficiation/upgrading of technology associated with high-volume reuse materials (i.e., fly ash and synthetic gypsum). This typically involves separation of fly ash from unburned and/or activated carbon, separation of marketable materials such as fly ash from other less desirable constituents, and stabilization/encapsulation of the trace metals such as mercury found in synthetic gypsum used in wallboard.

- Innovative technology and processes for utilizing CCRs in storage impoundments — NETL is interested in cost-effective approaches for removing, upgrading, and beneficially recycling CCRs from active and inactive storage impoundments.

Innovative technology, concepts, and processes for managing, stabilizing, monitoring, and/or closing-in-place inactive or legacy storage impoundments—focus on cost-efficient and environmentally sound alternatives to the physical removal of legacy CCR material. There is interest in innovative technologies, concepts, and processes to stabilize, neutralize, and/or immobilize trace metals and other contaminants in unlined or inadequately lined inactive or legacy disposal sites and monitor contaminant migration. In particular, use of plants or micro-organisms to stabilize or monitor contaminated materials/sites is of significant interest.

Innovative technology, concepts, and processes for managing, stabilizing, monitoring, and/or closing-in-place inactive or legacy storage impoundments—focus on cost-efficient and environmentally sound alternatives to the physical removal of legacy CCR material. There is interest in innovative technologies, concepts, and processes to stabilize, neutralize, and/or immobilize trace metals and other contaminants in unlined or inadequately lined inactive or legacy disposal sites and monitor contaminant migration. In particular, use of plants or micro-organisms to stabilize or monitor contaminated materials/sites is of significant interest.

- Innovative technology, concepts, and processes for CCR impoundment leachates—focus on innovative concepts to treat leachates and related discharges from both active and inactive (legacy) unlined or inadequately lined CCR impoundments and ponds.

The Emissions Control Program pursues technology advancements through onsite work at NETL, as well as by external funding opportunities, resulting in a suite of projects performed by industry and academia and overseen by NETL.

Explore the Site

NETL implements this effort as part of DOE’s Carbon Management Program.

Innovative technology, concepts, and processes for managing, stabilizing, monitoring, and/or closing-in-place inactive or legacy storage impoundments—focus on cost-efficient and environmentally sound alternatives to the physical removal of legacy CCR material. There is interest in innovative technologies, concepts, and processes to stabilize, neutralize, and/or immobilize trace metals and other contaminants in unlined or inadequately lined inactive or legacy disposal sites and monitor contaminant migration. In particular, use of plants or micro-organisms to stabilize or monitor contaminated materials/sites is of significant interest.

Innovative technology, concepts, and processes for managing, stabilizing, monitoring, and/or closing-in-place inactive or legacy storage impoundments—focus on cost-efficient and environmentally sound alternatives to the physical removal of legacy CCR material. There is interest in innovative technologies, concepts, and processes to stabilize, neutralize, and/or immobilize trace metals and other contaminants in unlined or inadequately lined inactive or legacy disposal sites and monitor contaminant migration. In particular, use of plants or micro-organisms to stabilize or monitor contaminated materials/sites is of significant interest.