NETL’s Hydrogen Research & Development

Hydrogen is integral to strengthening the nation’s supply of affordable, reliable, secure energy. Hydrogen is used in manufacturing of refined petroleum products, ammonia, fertilizer, and other fuels, and produces no greenhouse gas emissions when burned for power generation or industrial heating. Production processes that utilize carbon capture and storage technologies yield low carbon intensity hydrogen and ammonia that can be sold to export markets where there is significant demand for these products, strengthening the nation’s role as a major energy exporter.

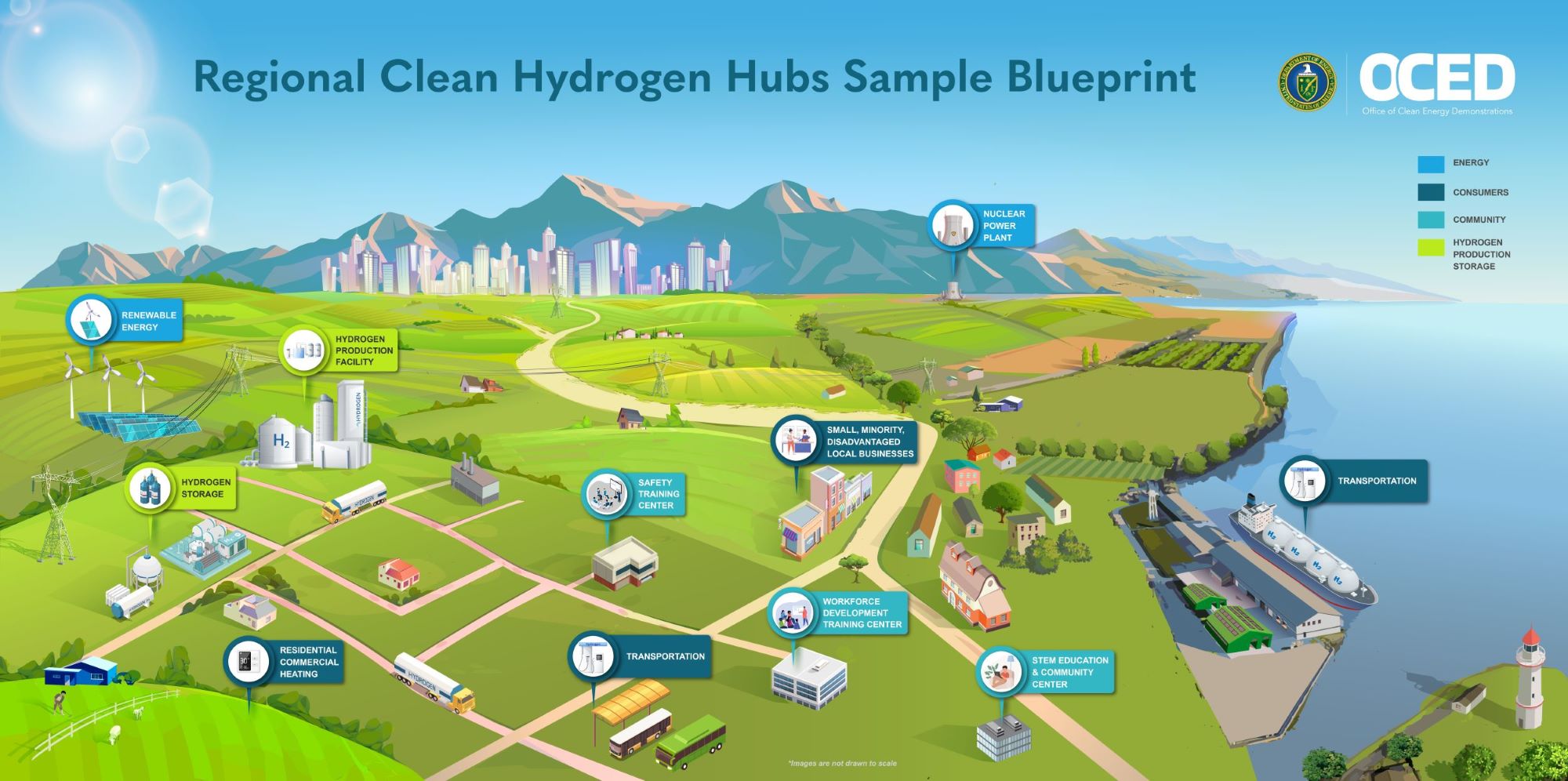

NETL is working across each area of the hydrogen value chain. Decades of research on carbon capture and storage (CCS) and large-scale fossil fuel production, infrastructure, and power systems positions the Lab to deliver solutions to challenging R&D problems for the hydrogen economy. NETL's expertise spans production, transportation, storage, and utilization of hydrogen, and is underpinned by strategic analyses and cross-cutting hydrogen needs such as sensors and materials.

Our Expertise

Clean Hydrogen Production

NETL’s R&D uses a variety of feedstocks (natural gas, coal, biomass, waste plastic) and processes to increase availability and reduce the costs of hydrogen production through:

Dry reforming via microwave technology

- Intensified modular process at point of use

- Multiple feedstocks

Dry reforming via microwave technology

- Intensified modular process at point of use

- Multiple feedstocks

Hydrogen and high-value solid carbon coproducts

- Carbon fiber and carbon nanotube coproducts offset hydrogen production cost

- Eliminates the need for CO2 transport and storage

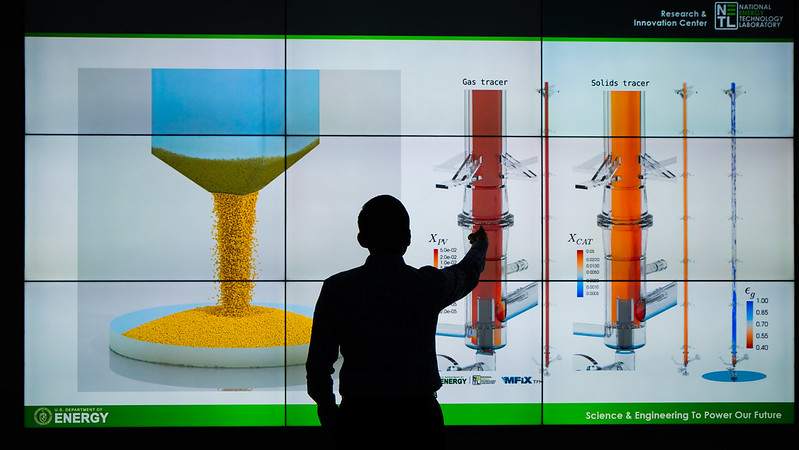

Optimization and scale-up of traditional and novel reactors

- Operating on coal, biomass, and waste feedstock mixtures

- Turning plastics into hydrogen and removing CO2 along the way

Alternative reforming and gasification technology with inherent CO2 capture and storage

Hydrogen production from water and excess electric power

- Multiscale modeling to minimize hydrogen production cost

- Electrode engineering for durability and reliability

Hydrogen Transport & Storage

NETL is leveraging its research in subsurface and pipelines to solve R&D challenges around the high costs of hydrogen transportation and bulk hydrogen storage, which are major barriers to a national hydrogen economy.

Pipeline and storage research includes:

- Subsurface hydrogen storage feasibility and analysis in saline, salt and depleted well geologic formations

- Early detection of hydrogen leaks using distributed fiber optic sensors, surface acoustic wave sensors, and/or electrochemical sensors

- Hydrogen pipeline transport cost model including compression needs for pure or blended hydrogen with natural gas

- Effects of hydrogen on material performance and developing liners/coatings to repurpose natural gas pipelines for hydrogen or natural gas/hydrogen blends

Hydrogen Utilization

The hydrogen market will grow in all sectors as its availability increases and price lowers.

NETL is studying ways to enable more hydrogen use in transportation, chemical production, electric power and industrial heating through:

- Increased combustion efficiency and reduced NOx emissions for hydrogen and ammonia-fueled gas turbines for power production

- Increased ammonia/hydrogen combustion efficacy and NOx management for industrial heating

- Solid oxide fuel cells and reversible solid oxide cells operability

- Microwave-assisted ammonia production from hydrogen

- Industrial heat (boilers, etc.) feedstock substitution

Crosscutting Hydrogen Needs

NETL’s research & development that crosses every part of the hydrogen value chain:

- Alloy development for improved hydrogen resistance

- Engineering hydrogen resistant surfaces

- Lifetime prediction modeling for materials in hydrogen service

- High hydrogen sensitivity and selectivity

- Ambient and harsh environments

- Hydrogen safety

- Environmental impact

- Long-distance optical fiber sensors

- Passive wireless sensors

- Electrochemical sensors

- Public access to data and models from DOE hydrogen projects to accelerate hydrogen commercial, regulatory, social and environmental goals.

Strategic Analysis

NETL analytical and assessment capabilities include hosting over 140 scientists and staff to evaluate and de-risk system designs and provide systematic decision-making to balance the competing goals of costs and efficiency. This world-class systems analysis is used to evaluate the deployment, integration and operability of the technologies and the hydrogen economy. Our crosscutting institutional experience includes:

Transport and storage configurations: Amassed knowledge and newly introduced cost model in pure hydrogen pipelines as well as leadership of the Subsurface Hydrogen Assessment, Storage and Technology Acceleration (SHASTA) project to evaluate economic and technical aspects of hydrogen storage in depleted wells, and salt and saline formations

Tools

NETL developed several tools that help partners conduct research or improve processes related to hydrogen. They are available for public use.

SHASTA H2 storage state of play

NETL leads the consortia that develop underground storage cost models and manages research, e.g., recent reservoir dynamics when converting natural gas fields to underground hydrogen storage.

CO2 saline storage cost model

CO2 The model provides CO2 subsurface storage assessments that consider existing regional assets with necessary invested infrastructure. It also estimates the national subsurface hydrogen assessment, storage and technology acceleration.

LCA of the natural gas supply chain

This analysis helps minimize upstream emissions from feedstock specific to the applicable natural gas basins and delivery routes.

Studies and Publications

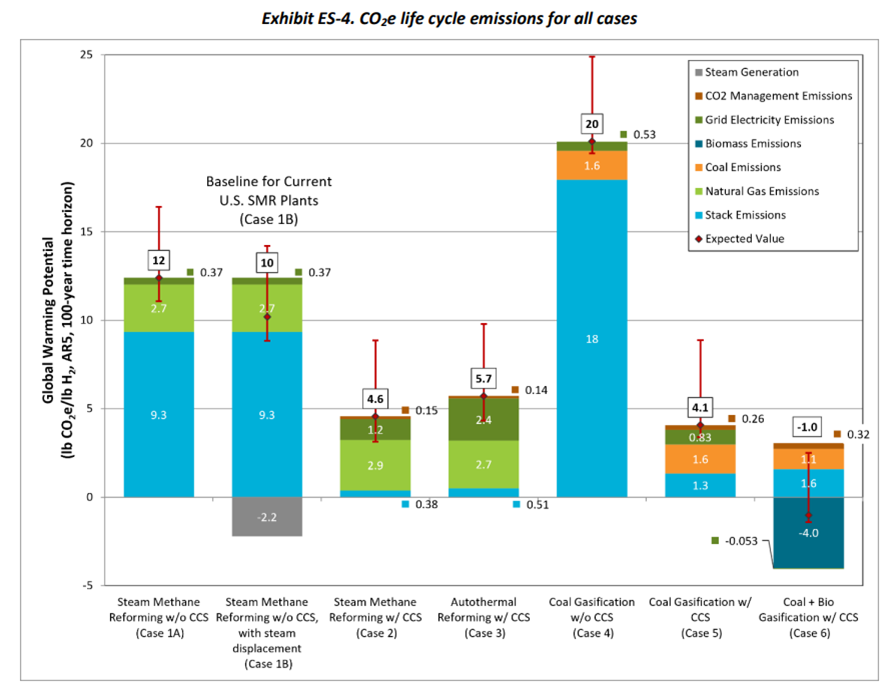

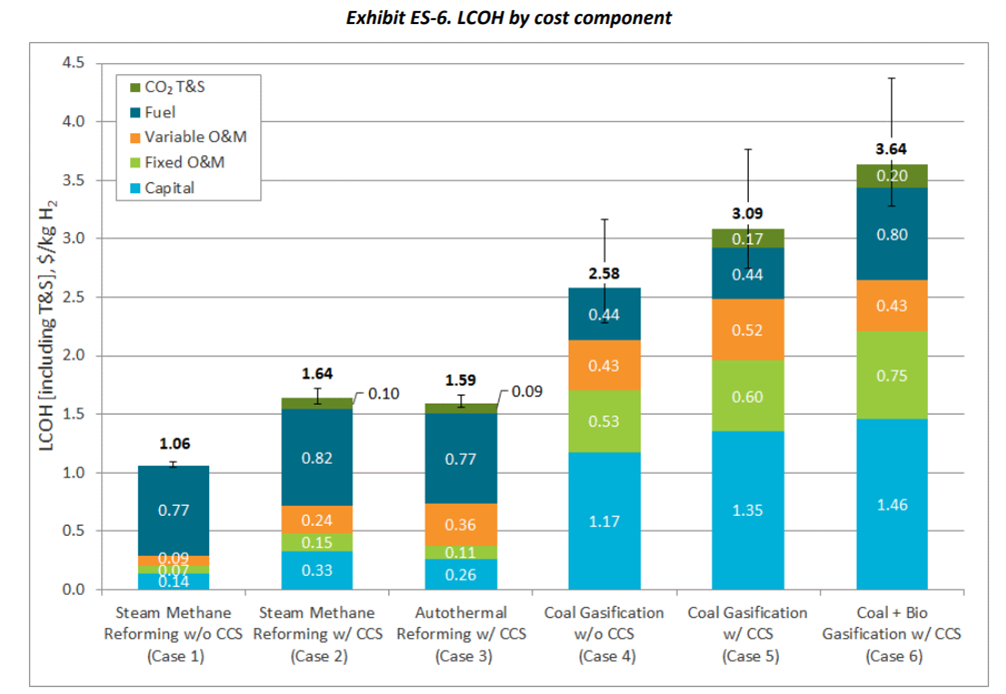

- Comparison of Commercial, State-of-the-Art, Fossil-Based Hydrogen Production Technologies

- Screening assessment of commercial and advanced pathways for achieving DOE’s Hydrogen Shot goal

- Technoeconomic Evaluation of Solid Oxide Fuel Cell Hydrogen-Electricity Co-Generation

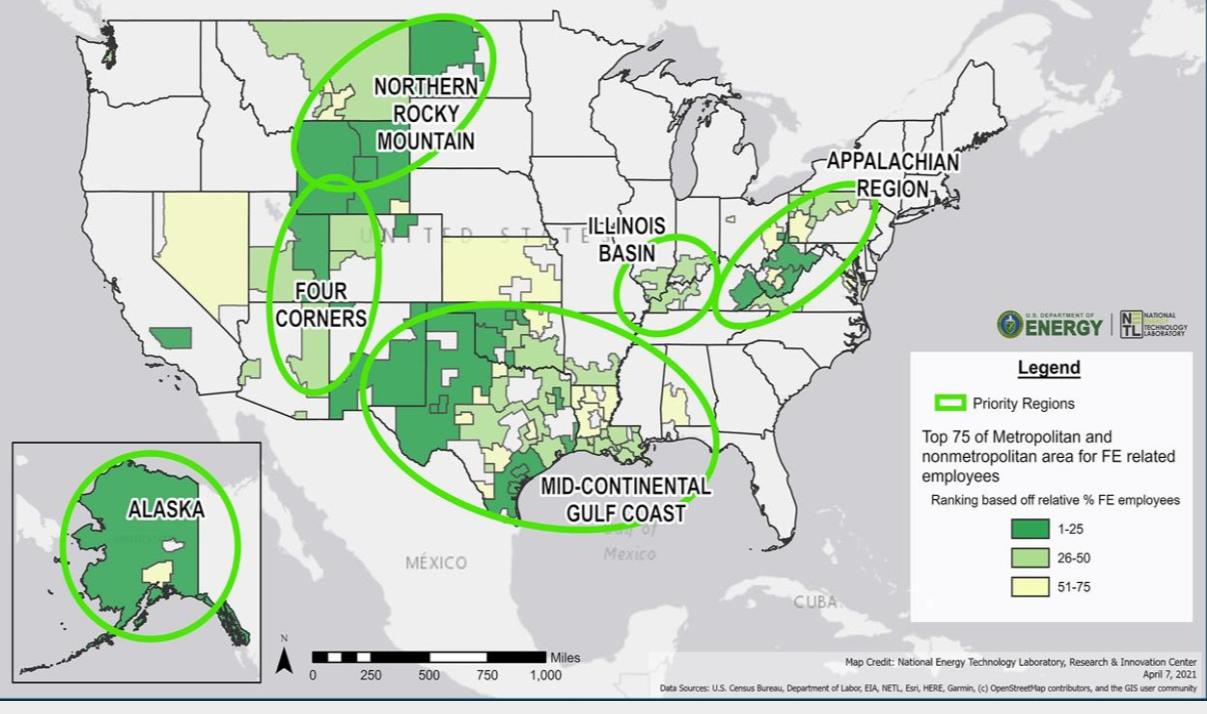

- Appalachian Hydrogen Infrastructure Study

- Methane pyrolysis

- Sensors

Learn more about Hydrogen with Carbon Management and our Natural Gas Decarbonization and Hydrogen Technologies Programs.