Materials Engineering and Manufacturing

Designing and developing affordable, durable materials for a resilient and abundant energy future for America.

NETL's Materials Engineering and Manufacturing (MEM) directorate designs and develops affordable, durable materials for energy applications at scales and by methods that readily translate to industrial practice. This strengthens the reliability of our nation's energy systems and ensures a resilient energy future.

MEM's research evaluates functional and structural materials at size and time regimes ranging from atomistic to pilot-plant scales. We combine computational and experimental methods to translate materials science concepts into practical technologies. This includes designing new materials and developing innovative manufacturing processes to characterize and evaluate performance in real-world service environments. Our research strengthens the security, affordability and reliability of our nation's energy systems and catalyzes the conversion of domestic energy resources into abundant power and valuable products, including critical minerals and materials (CMM).

Recent Publications

Materials Engineering and Manufacturing

Functional Materials

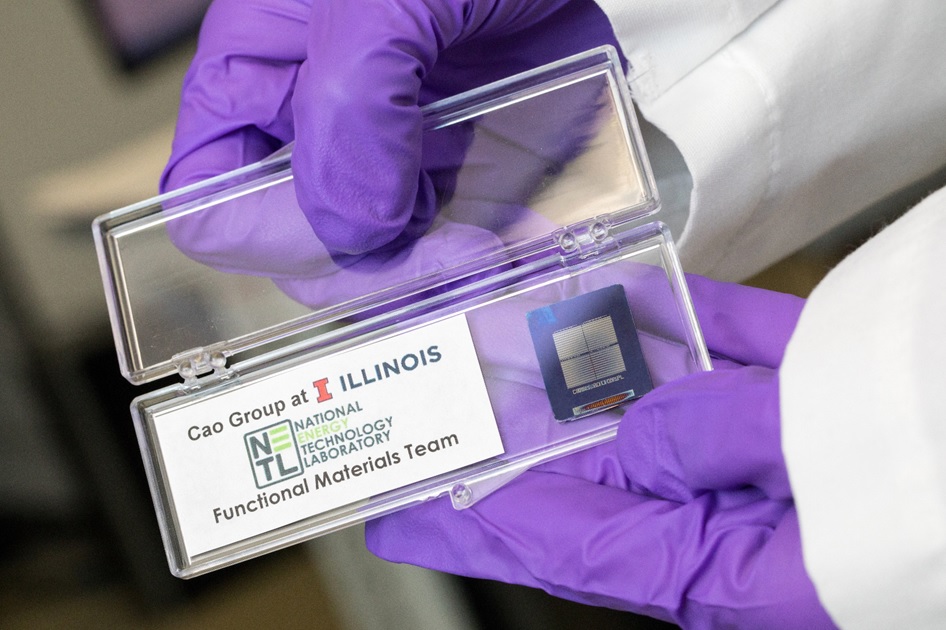

NETL's Functional Materials research focuses on developing cost-effective advanced materials to enable next-generation energy platforms.

Our materials expertise ranges from engineered nanomaterials, ionic liquids, polymers and carbons (graphite/graphene) to electro-ceramics. We leverage NETL's materials synthesis, characterization, fabrication and testing capabilities to develop specialized functional materials for separation, catalytic conversion, electronics and other applications needed to convert domestic energy resources into abundant power and valuable products, including CMM.

Materials Characterization

NETL's Materials Characterization research provides a deep understanding of materials chemical composition, microstructure and performance. We leverage our state-of-the-art analytical laboratories and extensive facilities to evaluate materials performance at conditions that simulate real-world service conditions, ultimately supporting the development of affordable, durable materials to meet the nation's energy challenges.

We develop sensing materials and systems to monitor critical infrastructure and process streams in real time. Our expertise in sensor platforms can be applied to a wide range of applications to improve the reliability of critical energy infrastructure and enhance the efficiency and effectiveness of energy and chemical processes.

Structural Materials

NETL's Structural Materials research focuses on developing cost-effective structural alloys and environmental barrier coatings that can withstand harsh conditions for long service durations to improve energy system integrity and reliability.

We develop materials to make the recovery, transportation and conversion of domestic fossil resources to fuels, chemicals and power more affordable and reliable. Our capability is anchored by NETL's Advanced Alloy Signature Center (AASC), which can prototype alloys between the laboratory, bench and production scales. This is ideal for accelerating alloy innovation for advanced energy systems and pyrometallurgical processes for CMM recovery and purification.

Key Physical and Virtual Facilities

NETL’s AASC is a complete alloy development facility capable of developing and prototyping advanced alloys for various U.S. industries, including energy, defense, aerospace, automotive, chemical processing and biomedical devices.

This facility helps companies and researchers create innovative materials by designing, engineering and testing specialty alloys that increase efficiency, reduce costs and improve performance with enhanced corrosion resistance, strength and durability. The facility can melt and process almost any alloy.

The AASC includes:

- Unique 13,000-square-foot melting facility

- 500-pound vacuum induction melting (VIM) furnace

- Other specialized equipment like air induction melting furnaces, vacuum arc remelting furnaces, electro slag remelting furnaces and button melting furnaces to develop new alloys for advanced energy applications

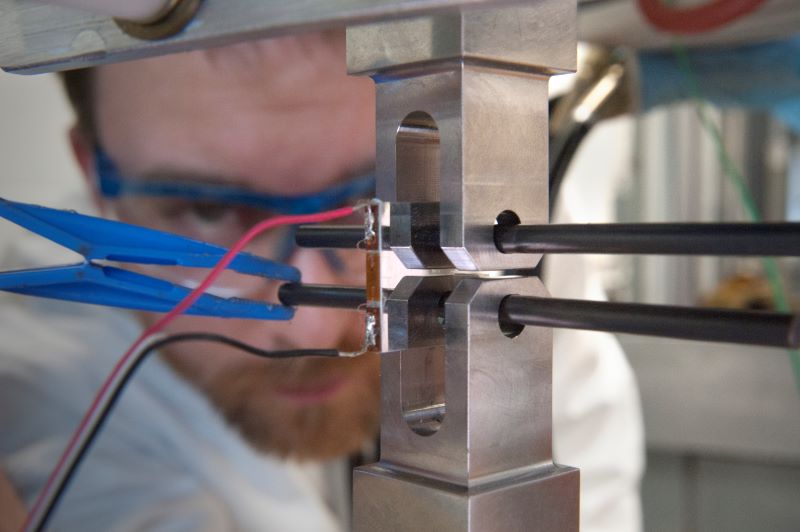

This facility supports the design and deployment of novel and cost-effective materials and devices for advanced sensing applications in energy systems, including harsh environments associated with advanced energy and resource recovery systems.

These laboratories help researchers and industry professionals focused on advancing manufacturing processes, modernizing the grid, and improving the overall reliability of fossil energy systems. For example, advanced sensors can detect and predict corrosion in natural gas pipelines, improving safety and efficiency.

Expertise includes:

- Fabricating long single-crystal fiber optics

- Depositing functionalized thin films

- Developing distributed interrogation techniques

- Detecting and preventing pipeline corrosion

NETL’s facilities support research on converting mining waste, plastics and other carbon resources into membranes, sorbents, solvents and catalysts that transform carbon-containing waste streams into revenue-generating products.

These facilities help U.S. companies and researchers develop innovative, carbon-based products that can achieve a 10-100x improvement in energy efficiency of computer microelectronics and a 15-25% increase in the mechanical strength of construction composites.

State-of-the-art equipment includes:

- Nanostructure fabrication tools

- Advanced material characterization instruments

This equipment has helped achieve scientific breakthroughs that range from revolutionizing high-tech products to enabling the discovery that nanostructured carbon additives made from charred coal waste can be used to develop low-cost, abundant composites that enhance cement for construction materials.