METALLIC

Accelerating Critical Minerals and Material Technology Deployment & Innovation

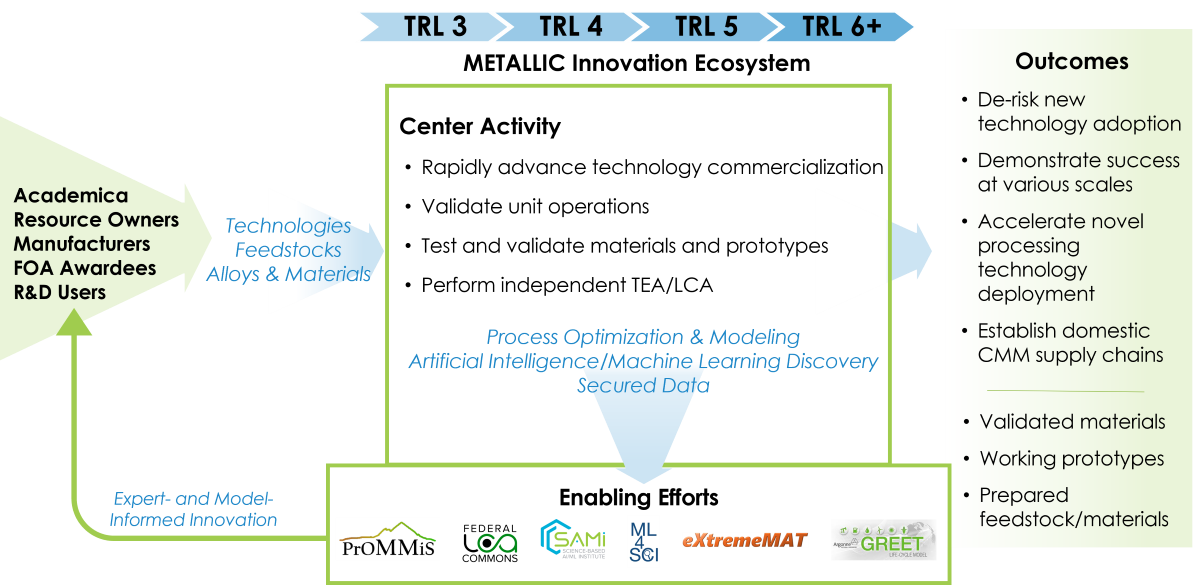

The Minerals to Materials Supply Chain Research Facility (METALLIC) builds upon existing Department of Energy efforts to accelerate the establishment of new, domestic critical minerals and materials (CMM) supply chains.

The NETL led effort brings together the resources of nine national labs to establish METALLIC as the destination to validate, improve, and help commercialize technologies developed by domestic entities, amplifying the impact of the Department of Energy (DOE) and other U.S. government investments. This innovative approach fosters an ecosystem of expertise and capabilities for accelerating and de-risking CMM technology development and commercialization.

Four Centers of Expertise Under One Virtual Roof

METALLIC operations are organized into four centers of expertise, each addressing a different area of the CMM supply chain. Each center focuses on selected activities, including equipment and test-beds for technology testing and validation. These centers are supported by an enabling activities team which provides a linkage across the centers. Click on each center and related activity below to learn more.

Center 1: Feedstock Beneficiation

Lead lab: NETL

Co-lead: INL, Berkeley Lab

Key partner labs: ANL, ORNL, PNNL

Focused on physical beneficiation pathways of conventional and unconventional ores and related CMM sources. Integrated beneficiation circuits at scales up to the 100s of kilograms per day will support developing minimally invasive, near-zero waste feedstock production, providing test beds for rare earth ores, other solid feedstocks and brines.

Center 2: Extractions and Separations

Lead lab: ORNL

Co-lead: ANL, INL

Key partner labs: Ames, Berkeley Lab, LLNL, NETL, NLR, PNNL

Focused on expanded supply and diversity of source materials via low-impact pathways with testbeds for novel unit operations, membrane solvent extractions and AI-guided autonomous chemistry.

Center 3: Refinery

Lead lab: Ames

Co-lead: NETL, LLNL

Key partner labs: ANL, Berkeley Lab, ORNL

The Center will accelerate technological innovations associated with refining critical material salts and oxides into metallic form. The Center will integrate capabilities across the national laboratory complex to establish facilities that will focus on four Flagship test-beds:

- Pyrometallurgical processing

- Electrochemical reduction

- Advanced reduction technologies

- Metal purification

Center 4: Alloy Development and Advanced Manufacturing (ADAM)

Lead lab: LLNL

Co-lead: PNNL, Ames

Key partner labs: ANL, NETL, NLR, ORNL

Focused on CM-efficient, high-performing, low-impact substitutes and components with solid-phase capability, advanced alloys, advanced semiconductors and advanced topology prototyping testbed.

Enabling Activities Team

Lead lab: NLR

Co-lead: ANL, NETL

Key partner labs: Berkeley Lab

Supports the four centers by providing comprehensive, .independent lifecycle analysis (LCA) and technoeconomic analysis (TEA) capabilities, developing data warehouse and interfaces; connecting analysis with experimentation, convening stakeholders, analyzing the state of technology and evaluating Technology Readiness Level (TRL) / Manufacturing Readiness Level (MRL).

Work With Us

METALLIC’s focus is grounded in establishing a CMM innovation ecosystem to (1) validate and test technologies, (2) connect technology developers to technology users (and vice versa) and (3) identify pathways for CMM production from new feedstocks. METALLIC is not a funding or a commercialization entity.

To achieve this, METALLIC provides a versatile platform for supporting CMM Research, Development, Demonstration, and Deployment (RDD&D) activities across supply chain segments, focusing on TRL 4 to 6+ and informed by input from DOE’s Office of Critical Minerals and Energy Innovation (CMEI) and Hydrocarbons and Geothermal Energy Office (HGEO), and the Critical Materials Collaborative (CMC).

Our primary users and partners include:

- Recipients of DOE funding (e.g., Notice of Funding Opportunity (NOFO) awardees)

- Industrial entities looking for technology solutions

- Innovators and technology developers

- Academic institutions and researchers

- Projects graduating from other DOE portfolios, such as the Critical Materials Innovation Hub (CMI)

- Other DOE offices

- Other agencies (e.g., the Department of Defense)

METALLIC serves a variety of users, helping them develop solutions to challenges in creating new domestic CMM supply chains and building a foundation for future innovation.

The METALLIC Team

Supporting Entities & Collaborations

Critical Materials Collaborative (CMC)

Critical Materials Collaborative (CMC)

Critical Materials Innovation (CMI) Hub

Critical Materials Innovation (CMI) Hub

DOE Office of Hydrocarbons and Geothermal Energy (HGEO)

DOE Office of Hydrocarbons and Geothermal Energy (HGEO)

Office of Critical Minerals and Energy Innovation (CMEI)

Office of Critical Minerals and Energy Innovation (CMEI)

Process Optimization and Modeling for Minerals Sustainability (PrOMMiS) Initiative

Process Optimization and Modeling for Minerals Sustainability (PrOMMiS) Initiative

%20(1).png)

.png)