PrOMMiS

Accelerating & De-Risking Critical Minerals & Materials (CMM) supply chain development

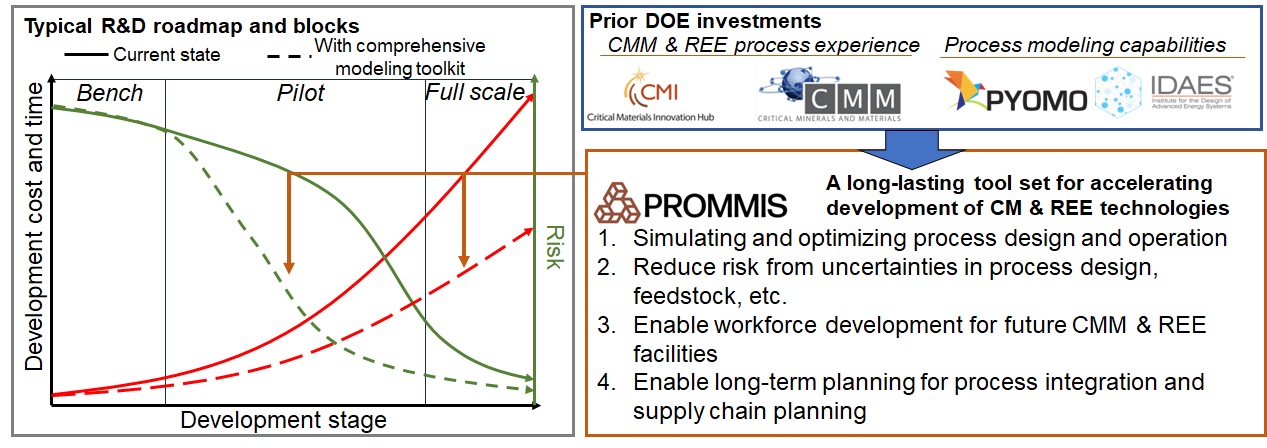

The Process Optimization & Modeling for Minerals Sustainability (PrOMMiS) initiative is focused on rapidly creating process modeling and optimization capabilities to de-risk and compress the “discovery to deployment” timeline for CMM technologies. PrOMMiS enables users to identify, design, scale and integrate CMM and REE processing systems, leveraging expertise from 50+ years of cumulative DOE investment in CMM R&D and modeling frameworks.

This multiple lab partnership, led by NETL, has created the first open source modeling platform to evaluate pathways for CMM production and perform multi-criteria optimizations, allowing rapid evaluation of how novel system designs impact environmental and economic performance. These foundational capabilities enable the broader modeling and design of optimized domestic CMM supply chains—strengthening U.S. national security, economic competitiveness, and environmental responsibility.

Approach

PrOMMiS is leveraging extant data and models to understand the energy needed for this emerging industry. We will:

- Leverage and extend DOE modeling capabilities from the Institute for the Design of Advanced Energy Systems (IDAES), the Carbon Capture Simulation for Industry Impact (CCSI2), and WaterTAP to CMM processing pathways

- Establish the capability rapidly by leveraging existing projects (recently completed or underway) as "case studies" for testing & validation

- Create a flexible platform that can be applied to future CMM challenges

- Actively engage with industry, academia, and government entities to ensure PrOMMiS has the greatest impact to stakeholders

Work/partner with us

The PrOMMiS team has started to work directly with industry partners and other entities who want to scale-up or optimize their CMM & REE technologies. Our toolkit helps maximize learning throughout the development cycle – from TRL 3 through 8 – to accelerate and de-risk technology scale-up and deployment.

As an open source modeling initiative, PrOMMiS is also focused on providing capabilities that meet the needs of domestic CMM researchers, technology developers and modelers.

To partner with the PrOMMiS team, contact us at prommis-support@lbl.gov

To learn more about the PrOMMiS capabilities and to track the development of the initiative, register for our semi-monthly stakeholder webinars and join our email distribution list. Click here to learn more.

Tools

PrOMMiS can be found on GitHub: https://github.com/prommis

Tools created as part of this collaborative effort are extending capabilities that have successfully supported other programs with a "deploy now" mandate, notably CCSI2 for FECM’s carbon capture program and WaterTAP for the National Alliance for Water Innovation (NAWI).

This includes:

- A model and cost library for simulation, optimization, techno-economic analysis, and scale-up of mineral processing technologies

- Optimization capabilities for high-level screening of process configurations to identify the most promising flowsheets

- Optimization-under-uncertainty approaches to produce designs that are robust to process variability

- Capabilities for uncertainty quantification to inform the design of pilot-scale experiments and maximize knowledge gained from budget- and schedule-constrained experimental campaigns

%20(1).png)

Critical Materials Innovation Hub (CMI)

Critical Materials Innovation Hub (CMI)