- x

- Powder River Basin (Geological)

- Madison Formation

- Wallula Basalt Pilot

- Cropland (Terrestrial)

- Forestry (Terrestrial)

- Rangeland (Terrestrial)

Carbon Storage Atlas

Why this Location

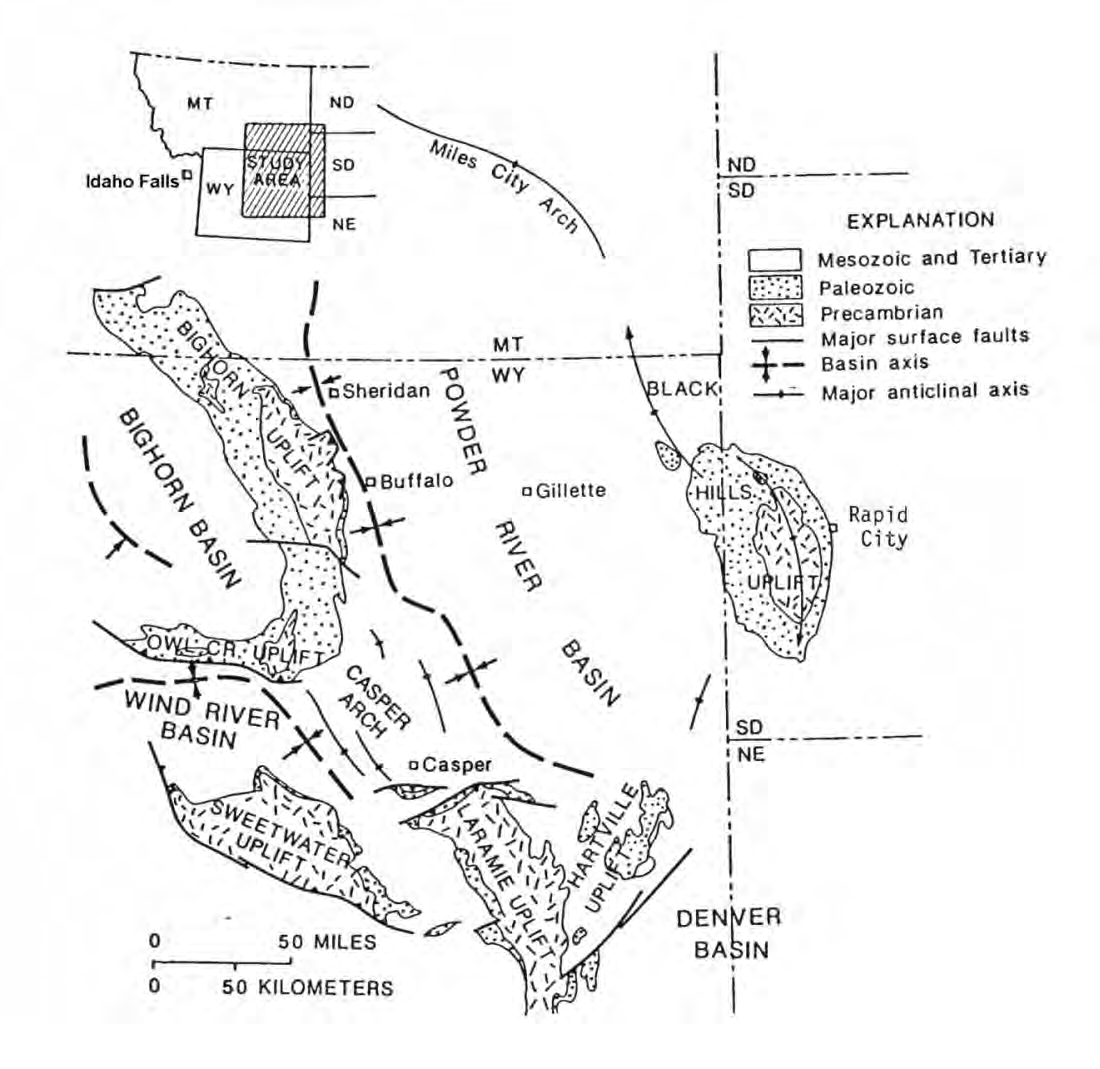

This specific setting was selected because of its large carbon dioxide (CO2) storage potential, its national importance as the largest coal-producing basin in the United States, and its location within the Big Sky Carbon Sequestration Partnership (BSCSP) area. The Powder River Basin is located largely in northeastern Wyoming, with a small portion extending into southeastern Montana (see Figure 1). The basin is a deep, northerly trending, asymmetric, mildly deformed trough, approximately 400 kilometers long and 160 kilometers wide.

Main Research Q&As Discovered

A design study for a possible field validation test during Phase III was carried out. The focus of this study was to understand and demonstrate the effects of two important processes: (1) technical and economic issues associated with injecting a pure carbon dioxide (CO2) stream into a coal seam rather than an unseparated flue gas stream, and (2) coal swelling effects on permeability changes and their incorporation into a coalbed reservoir simulator.

Sorption-induced strain, also commonly referred to as coal swelling/shrinkage, was investigated. A new method of obtaining sorption-induced strain was developed that greatly decreases the time necessary for data collection and increases the reliability of the strain data. A new permeability model was developed that can be directly applied to coal permeability data obtained under laboratory stress conditions, which are different than field stress conditions.

An economic feasibility study of CO2 storage in unmineable coal seams in the Powder River Basin of Wyoming was conducted, and economic analyses of CO2 injection options were compared. Results showed that injecting flue gas to recover methane from coalbed methane (CBM) fields is marginally economical; however, this method will not significantly contribute to the need to store large quantities of CO2. Separating CO2 from flue gas and injecting it into the unmineable coal zones of the Powder River Basin seam is currently uneconomical, but can effectively store more than 78,000 metric tons of CO2 per acre while recovering methane to offset costs. The cost to separate CO2 from flue gas was identified as the major cost driver associated with CO2 storage in unmineable coal seams. Improvements in separations technology alone are unlikely to drive costs low enough for CO2 storage in unmineable coal seams in the Powder River Basin to become economically viable.

Lessons Learned

Unmineable coalbeds are potentially large storage reservoirs for the storage of anthropogenic carbon dioxide (CO2) and offer the benefit of enhanced methane production, which can offset some of the costs associated with CO2 storage. An economic feasibility study in the Powder River Basin of Wyoming was conducted and economic analyses of CO2 injection options were compared. The cost to separate CO2 from flue gas was identified as the major cost driver associated with CO2 storage in unmineable coal seams in the Powder River Basin. In order to achieve economic viability, some form of government incentive would need to be imposed to drive the cost to separate CO2 from flue gas to less than zero. Technological breakthroughs could aid the economics, but would not be expected to accomplish all that is necessary.

Links to EDX

Analysis of CO2 Separation from Flue Gas, Pipeline Transportation, and Sequestration in Coal

This document assesses the costs associated with separating the carbon dioxide (CO2) from flue gas and then injecting it into a coal seam. The technical challenges and costs associated with CO2 separation from flue gas and transportation of the separated CO2 from the point source to an appropriate storage target are also analyzed in this report

https://edx.netl.doe.gov/dataset/secarb-airborne-magnetic-and-conductivity-survey

This document assesses the costs associated with separating the carbon dioxide (CO2) from flue gas and then injecting it into a coal seam. The technical challenges and costs associated with CO2 separation from flue gas and transportation of the separated CO2 from the point source to an appropriate storage target are also analyzed in this report

Enhanced_Coal_Bed_Methane_Recovery_and_CO2_Sequestration

This report summarizes work done at Idaho National Laboratory in support of Phase II of the Big Sky Carbon Sequestration Partnership (BSCSP).