Carbon Storage Atlas

- Why This Location

- Main Research Q&As Discovered

- Lessons Learned

- Story of Interest

- Geologic Details

- Sites

Site: Plant Daniel Project

Lat/Long

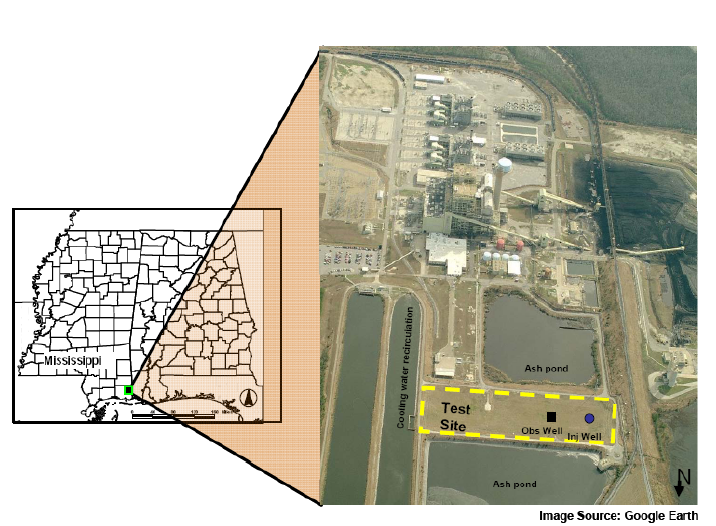

Location of Plant Daniel: (Taken from DOE-NT42590-01-small pdf)

- Ten miles north of the city of Pascagoula in Jackson County, Mississippi.

- Section 11 of Township 6 south, Range 6 west of Jackson County, Mississippi.

Why this Location?

The Southeast Regional Carbon Sequestration Partnership (SECARB) Black Warrior site was built around a mature coalbed methane (CBM) well that had underperformed over its life. The Chevron 17-09-122 well is in an area with multiple coal zones that were perforated and hydrofractured in separate stages, as is typical of the Black Warrior Basin. The reservoir properties of each coal seam tend to differ greatly, particularly because coal is a stress-sensitive rock type, and so permeability tends to decrease exponentially with depth. The well is in an area where the coalbeds are thick and continuous and appear favorable for geologic storage and carbon dioxide (CO2)-enhanced coalbed methane (ECBM) recovery. The site also was ideal for monitoring the performance and hydraulic isolation of each coal zone to understand subsurface flow and the ability to protect underground sources of drinking water (USDWs).

Main Research Q&As Discovered

The primary goal of this project was to demonstrate safe and secure injection and storage of carbon dioxide (CO2) in the Lower Tuscaloosa reservoir. The Lower Tuscaloosa was selected for geologic characterization because of its favorable, yet unproven, CO2 storage potential. Several large-capacity saline reservoirs are also present, providing stacked storage potential. The storage formations at Plant Daniel are overlain by extensive, thick, low-permeability confining units, and the lack of significant faulting and fracturing reduces the leakage risk considerably.

In October 2008, approximately 2,722 metric tons of CO2 were injected into the Lower Tuscaloosa. Field injectivity was superior to the best modeling estimates, due to higher-than-anticipated permeability values. The CO2 injection demonstrated that conventional oilfield injection well design, drilling, and completion methodologies can be adapted for use in CO2 injection well drilling. Carbon dioxide injection was monitored using both shallow and deep methods. Shallow methods included groundwater geochemistry, soil CO2 flux, and surface monitoring for tracers injected with the CO2 stream. Results from these monitoring methods suggested that no CO2 leakage from the injection zone occurred. Deep methods included cased-hole pulsed neutron logging and vertical seismic profiling. Neither of these methods were able to track the CO2 plume, highlighting the difficulty of tracking a small CO2 plume in the subsurface.

The most important lesson learned at Plant Daniel is the importance of using tools outside the conventional toolkit. The use of high-resolution reservoir characterization tools and advanced reservoir simulation tools will be invaluable for predicting long-term injection and reservoir performance. Many large-scale, deep saline reservoir injection demonstrations will be conducted in areas with geologic strata that have little or no available reservoir data. Early gathering of detailed characterization data used in reservoir simulations is critical in predicting short-term migration paths of a CO2 plume, and long-term mechanisms of CO2 immobilization.

Lessons Learned

Lessons learned from the Plant Daniel project that were directly translatable to Phase III projects include the impact of reservoir architecture on carbon dioxide (CO2) storage and the carryover of oil and gas industry experience to saline storage. A storage reservoir’s internal architecture can have an important impact on its ability to safely and efficiently store CO2 in a limited area. Injection of CO2 into reservoirs containing alternating sand and low-permeable shale baffles (or confining layers) results in greater vertical CO2 dispersion and smaller plume footprint compared to a thick, sand reservoir without layers. Limiting the plume footprint will improve project economics by reducing the size of the monitored area and associated capital and operating costs and help minimize the cost of acquiring pore space access/use rights. In addition, dispersing the plume across many layers will reduce the potential for leakage compared to concentrating CO2 directly below the primary caprock.

Story of Interest

The U.S. Gulf Coast region contains numerous stacked saline reservoirs with large storage capacity that can be readily utilized to host multiple commercial-scale carbon dioxide (CO2) storage projects. One such reservoir, the Lower Tuscaloosa Group “Massive Sand,” was investigated by the Southeast Regional Carbon Sequestration Partnership (SECARB) and found to have excellent permeability and porosity. Carbon dioxide injection into the Lower Tuscaloosa demonstrated that the formation has high-CO2 injectivity and storage capacity. More importantly, the project demonstrated that CO2 can be handled and injected safely and securely without impacting the environment, worker health and safety, and electric power generation at Plant Daniel.

SECARB demonstrated to Southern Company and Mississippi Power Company that onsite CO2 storage activities, including drilling, testing, monitoring, and CO2 injection, did not affect the plant’s day-to-day operations. These results helped convince Southern Company management to support the Phase III “Anthropogenic Test” hosted by subsidiary Alabama Power Company at Plant Barry and the Project ECO2S Carbon Storage Assurance Facility Enterprise (CarbonSAFE) demonstration hosted by subsidiary Mississippi Power Company at the Kemper County energy facility.

Geologic Details

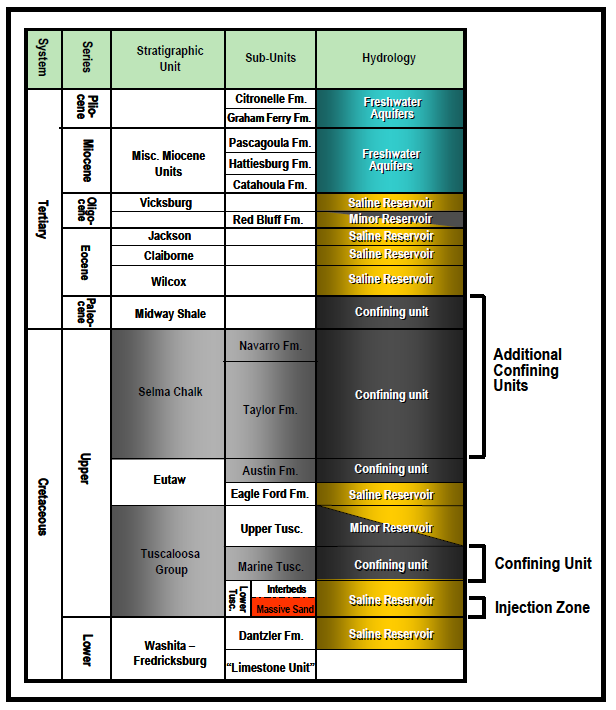

Plant Daniel lies within the Mississippi-Alabama Gulf Shelf geologic province, located on a passive-continental margin that has persisted from the Triassic to present day. Plant Daniel is underlain by a thick sedimentary section of Jurassic through Tertiary age marine shale, limestone, marl, and sandstones. The carbon dioxide (CO2) injection zone is the Lower Tuscaloosa Group “Massive Sand,” and the primary and secondary confining units are the Tuscaloosa Marine Shale and the Selma Chalk, respectively (Figure 2).

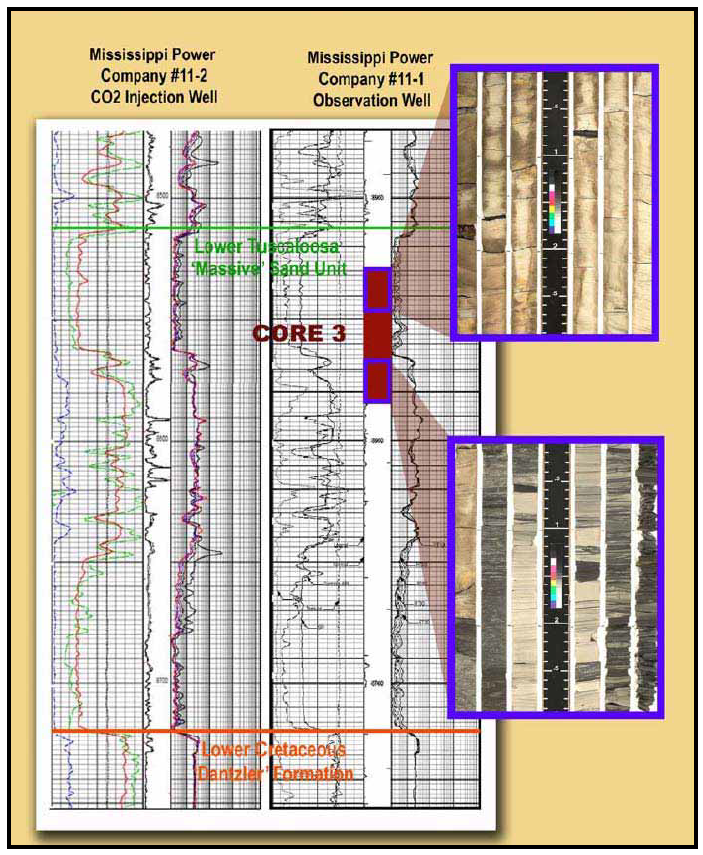

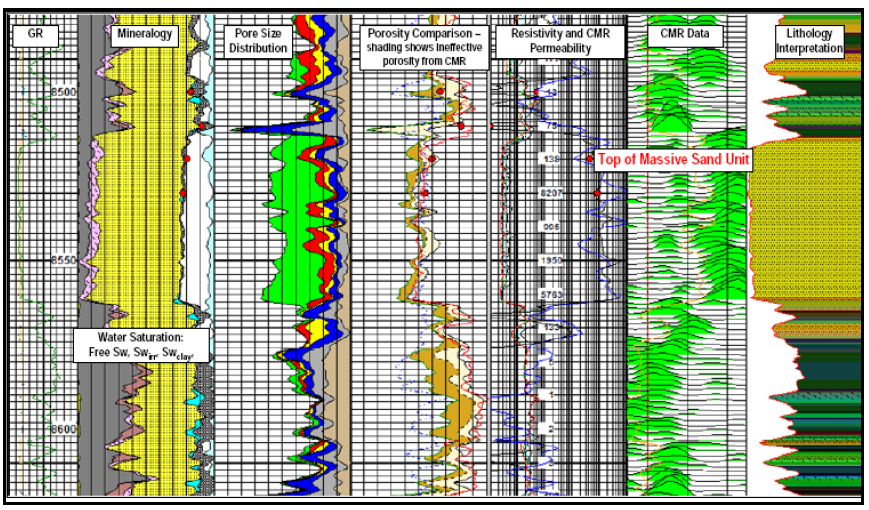

The Lower Tuscaloosa represents a tidal-influenced deltaic distributary channel environment. The overlying Tuscaloosa Marine Shale consists of interbedded grey mudstone/shale, siltstone, and fine-grained sandstone, representing a marine shelf environment. The Selma Chalk is a tan, silty, very-fine grained, highly burrowed, fossiliferous limestone/chalk, representing an outer carbonate shelf environment. A conventional geophysical log suite was obtained in both the injection and observation wells. Figure 3 is a side-by-side presentation of gamma ray, spontaneous potential and electrical resistivity well logs for the injection and observation wells. Geo-processed logs provide an interpretation of reservoir petrophysical characteristics, allowing comparison of the pore size distribution, porosity, and immobile water saturation between injection and non-injection zones. Figure 4 is an example of the geo-processed log interpretation across the upper Lower Tuscaloosa Group “Massive Sand” injection zone.