Carbon Storage Atlas

- Why This Location

- Main Research Q&As Discovered

- Lessons Learned

- Story of Interest

- Geologic Details

- Sites

Site: Black Warrior Coal Test

Lat/Long

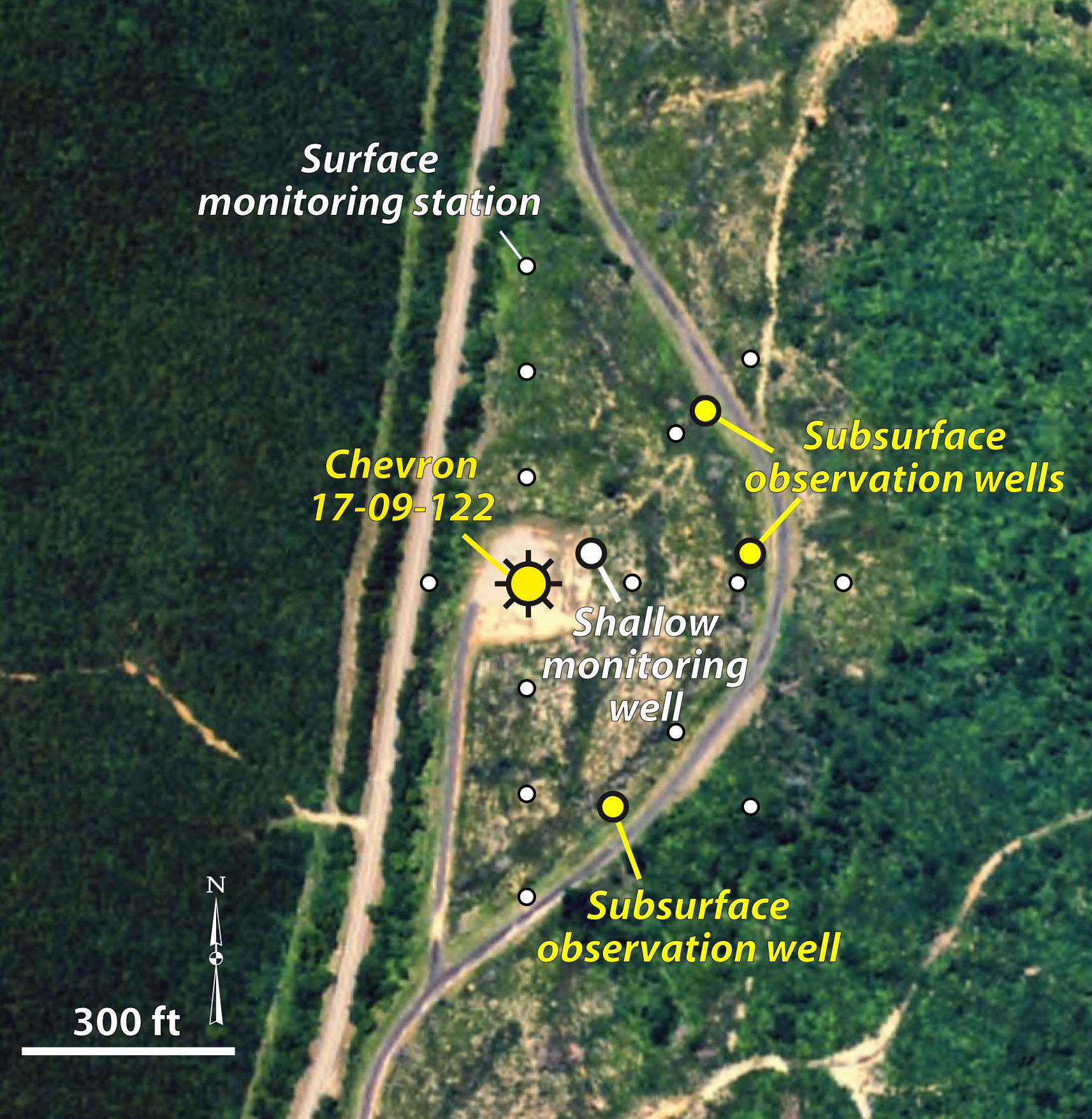

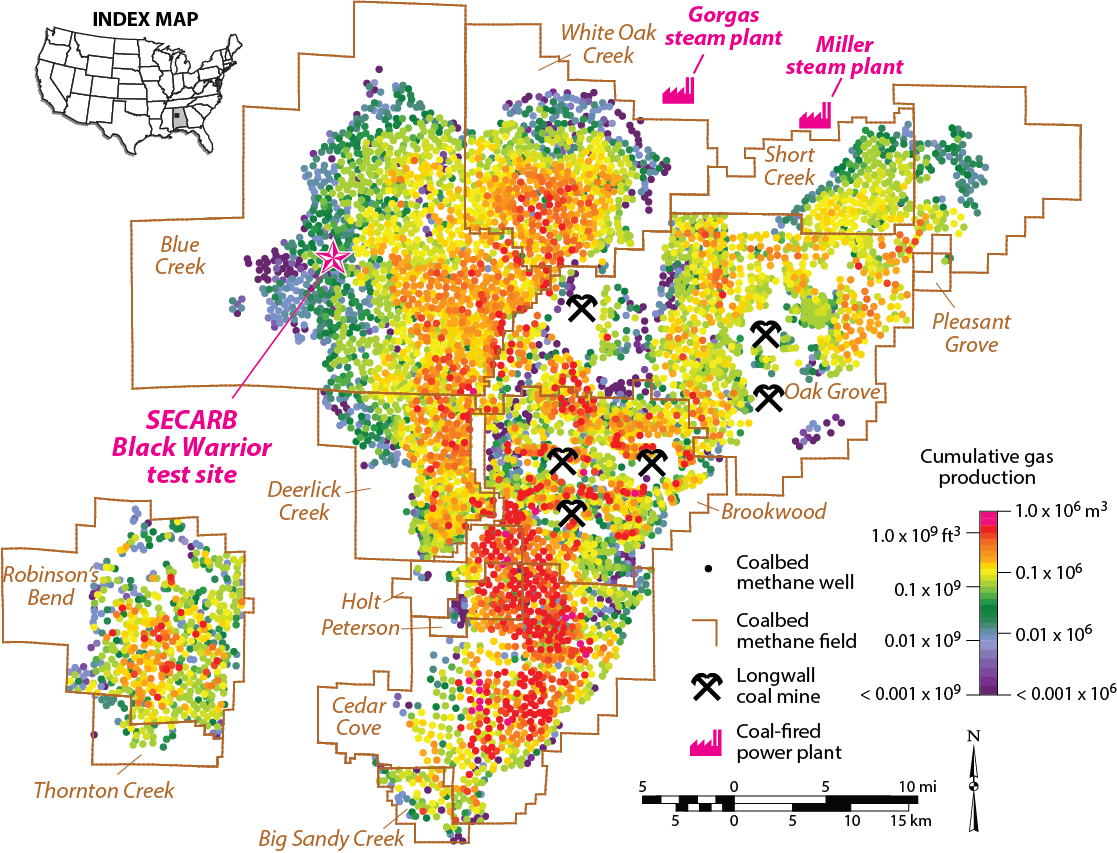

The Southeast Regional Carbon Sequestration Partnership (SECARB) Black Warrior coal test was hosted by El Paso Exploration and Production, Inc., in Blue Creek Field, Tuscaloosa County, Alabama, and was led by the Geological Survey of Alabama. The test well was the Chevron 17-09-122 well (State Oil and Gas Board Permit no. 12540-C).

The precise location of the well is 33.47691 N, -87.49419 W.

Why this Location?

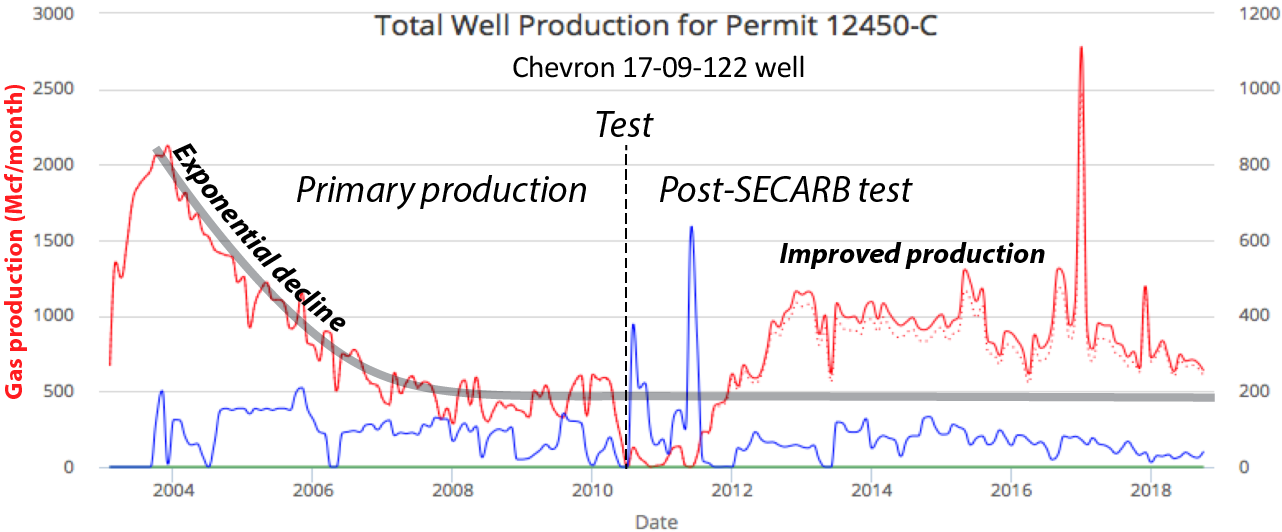

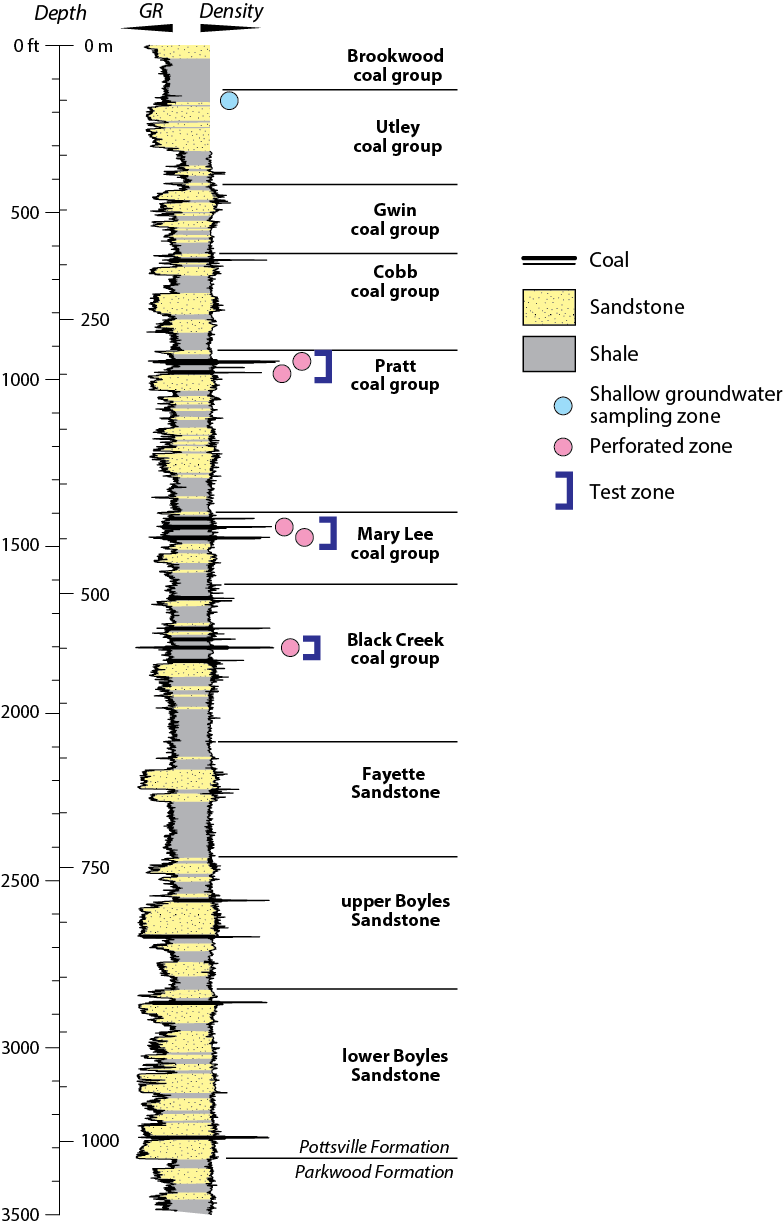

The Southeast Regional Carbon Sequestration Partnership (SECARB) Black Warrior site was built around a mature coalbed methane (CBM) well that had underperformed over its life. The Chevron 17-09-122 well is in an area with multiple coal zones that were perforated and hydrofractured in separate stages, as is typical of the Black Warrior Basin. The reservoir properties of each coal seam tend to differ greatly, particularly because coal is a stress-sensitive rock type, and so permeability tends to decrease exponentially with depth. The well is in an area where the coalbeds are thick and continuous and appear favorable for geologic storage and carbon dioxide (CO2)-enhanced coalbed methane (ECBM) recovery. The site also was ideal for monitoring the performance and hydraulic isolation of each coal zone to understand subsurface flow and the ability to protect underground sources of drinking water (USDWs).

Main Research Q&As Discovered

The Black Warrior Basin near Birmingham and Tuscaloosa, Alabama, is the birthplace of the modern coalbed methane (CBM) industry and remains a key source of natural gas in the southeastern United States. The test was designed to increase understanding of reservoir performance and the potential for carbon dioxide (CO2) storage and enhanced recovery in mature CBM reservoirs.

Key questions that guided the field test are how much natural gas remains in coal seams after primary recovery? How much CO2 can be stored, and can gas recovery be improved? Does CO2 remain confined in the injection zones? Do permeability and injectivity vary among coal zones? How quickly would CO2 migrate in the reservoir, and would CO2 breakthrough to monitoring wells? Would CO2 flow preferentially along hydrofractures or cleat systems? Could reservoir behavior be predicted using simulation techniques?

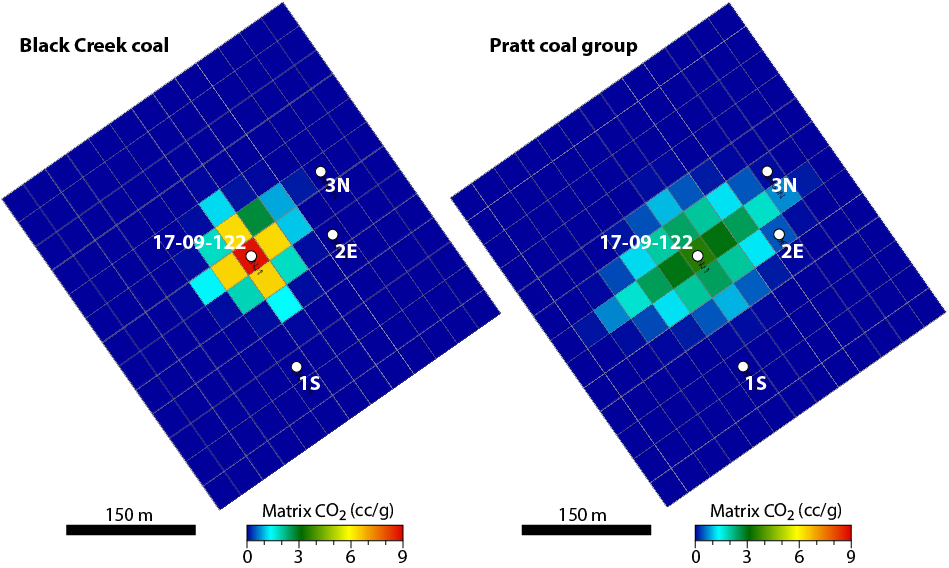

Coring coal seams indicates that the thickest coalbeds had been drained effectively during production, whereas thinner and deeper beds still had high gas content that would have been attractive before development. Simultaneous monitoring of each coal zone and a shallow aquifer indicate strong isolation of each zone and that drinking water can be protected. Injecting approximately 228.6 metric tons of CO2 confirmed that permeability and injectivity decrease exponentially at depth, with preferred migration along face cleats in the deepest coal and in the direction of hydrofractures in shallow coal. Breakthrough occurred at the end of the experiment in the shallowest coal zone in a monitoring well that was placed along the expected hydrofracture direction, confirming a high degree of reservoir anisotropy. Results were consistent with reservoir models that predicted elongated CO2 plumes and breakthrough in the shallow Pratt coal zone. Post-injection production data indicate that reservoir performance was greatly improved after the test, indicating great potential for improving long-term well performance using small quantities of CO2.

Lessons Learned

The Southeast Regional Carbon Sequestration Partnership (SECARB) Black Warrior coal test was developed in concert with a similar U.S. Department of Energy (DOE)/National Energy Technology Laboraotry (NETL)-sponsored test led by Virginia Tech and CNX Energy in southwestern Virginia that explored the storage potential of central Appalachian coalbed methane (CBM) reservoirs. Lessons learned from these tests were used to develop a larger test that was performed in Buchannan County, Virginia, and was led by Virginia Tech. These lessons include that small quantities of carbon dioxide (CO2) can have a significant impact on well performance and that large volumes of natural gas remain unswept by primary recovery. The Phase II Black Warrior and Virginia tests showed the potential for storing significant amounts of CO2 by adsorption in depressurized reservoirs. These tests, however, were effectively huff-and-puff operations, and significant work remained to understand the applicability of five-spot flooding programs to store CO2 and enhanced coalbed methane (ECBM) recovery—this was the focus of the Buchannan County test.

Story of Interest

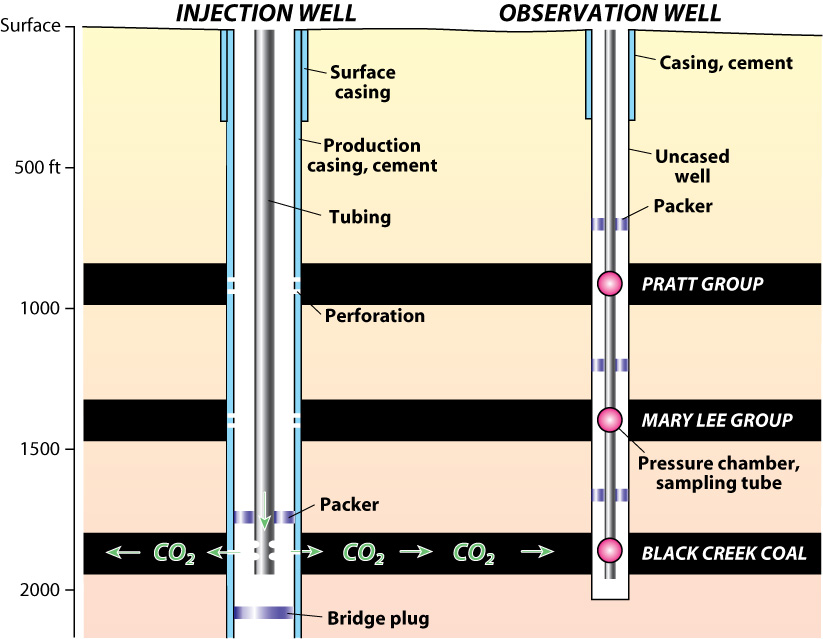

Monitoring was a key focus of the Southeast Regional Carbon Sequestration Partnership (SECARB) Black Warrior coal test. The challenge was to monitor multiple zones simultaneously for pressure and obtain fluid samples. Four monitoring wells were drilled approximately 100 meters from the injection well. Three of the wells went to reservoir depth, and the well access road enabled ready access to monitoring sites. In these three wells, coiled tubing was set in each target coal zone to monitor pressure and recover gases. Each target coal zone was isolated by inflatable packers. The production well was converted into an injector and instrumented with surface pressure gauges and a downhole gauge to monitor pressure and temperature. A shallow monitoring well was drilled at the production well pad to monitor the chemistry of groundwater in a shallow coal seam, which constitutes the underground sources of drinking water (USDW) in the project area.

Setting the tubing in the wells required exceptional care. One coiled tube had to be strung into each coal zone for pressure monitoring, a second set of tubes was used for gas sampling, and a third set of tubes was needed to keep the packers inflated with nitrogen. Accounting for all of the tubing and being sure the correct lines reached the pressure transducers and sampling ports was a tricky task. When SECARB began recording data, everything worked very well, each coal zone was shown to be hydraulically isolated, and the data provided exceptional insight into the response of different coal zones to carbon dioxide (CO2) injection.

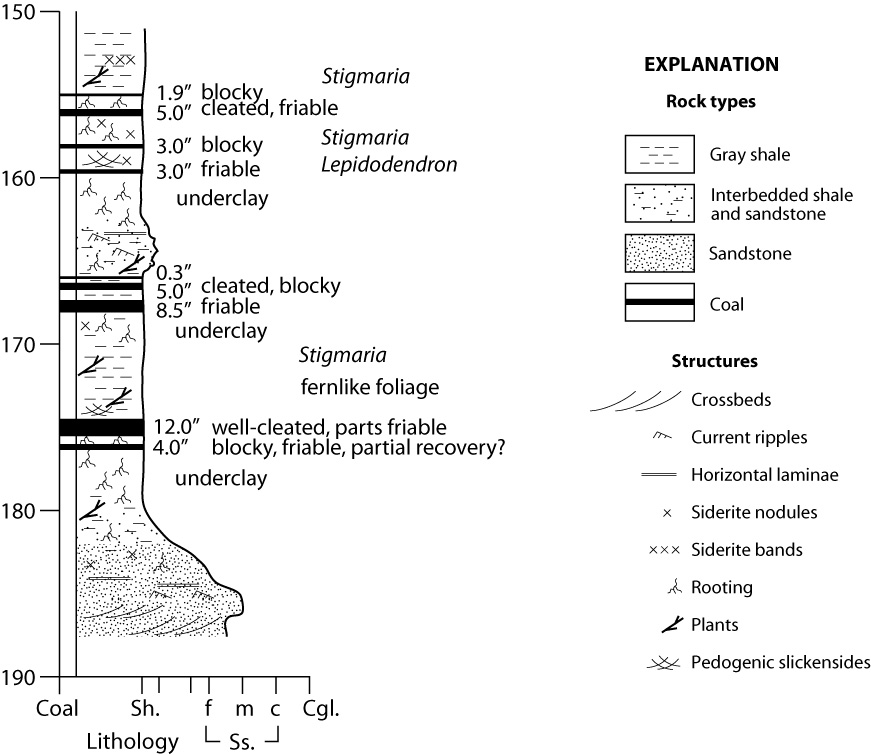

Geologic Details

Operations at the Southeast Regional Carbon Sequestration Partnership (SECARB) Black Warrior test site were varied, and included coring, desorption testing, geophysical well logging, and reservoir modeling. Detailed results of the field test, including the pressure response in each coal zone, are available in Pashin et al., (2015). Some of the key graphics summarizing site geology are represented in the figures provided.

Pashin, J. C., Clark, P. E., McIntyre-Redden, M. R., Carroll, R. E., Esposito, R. A., Oudinot, A. Y., and Koperna, G. J., Jr., 2015, SECARB CO2 injection test in mature coalbed methane reservoirs of the Black Warrior Basin, Blue Creek Field, Alabama: International Journal of Coal Geology, v. 144, p. 71-87, http://dx.doi.org/10.1016/j.coal.2015.04.003.

.png)