Carbon Storage Atlas

- Why This Location

- Main Research Q&As Discovered

- Lessons Learned

- Story of Interest

- Geologic Details

- Links to EDX

- Sites

Site: SECARB Stacked Storage Site at Cranfield

Lat/Long

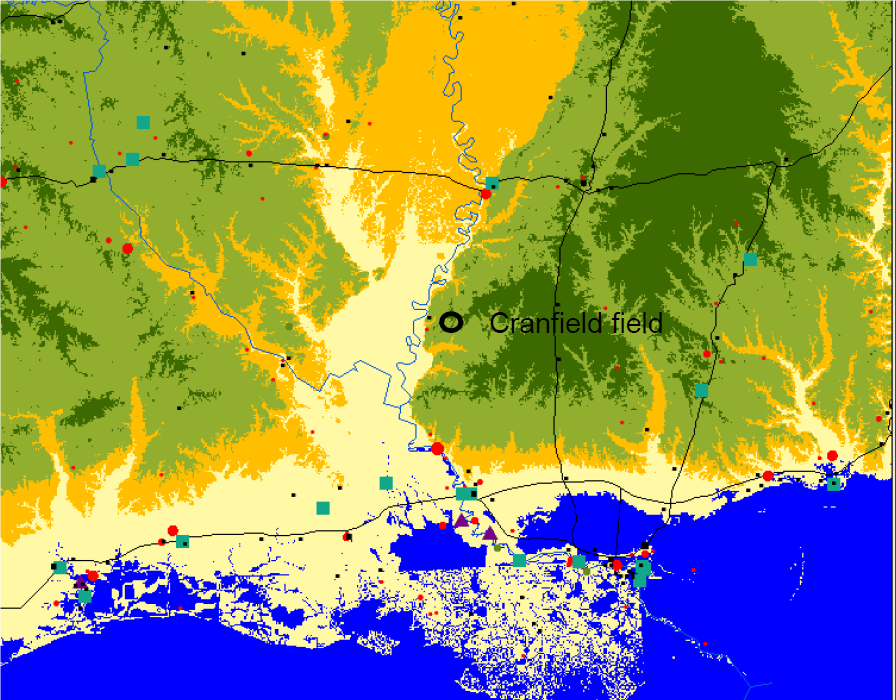

The Southeast Regional Carbon Sequestration Partnership (SECARB) Stacked Storage Site was hosted by Denbury Onshore LLC at the Cranfield Field, approximately 24.1 kilometers (15 miles) east of Natchez, Mississippi. The Ella G Lees #7 observation well was located in Adams County, Mississippi.

31°42’35” N, 91°10’14” W

Why this Location?

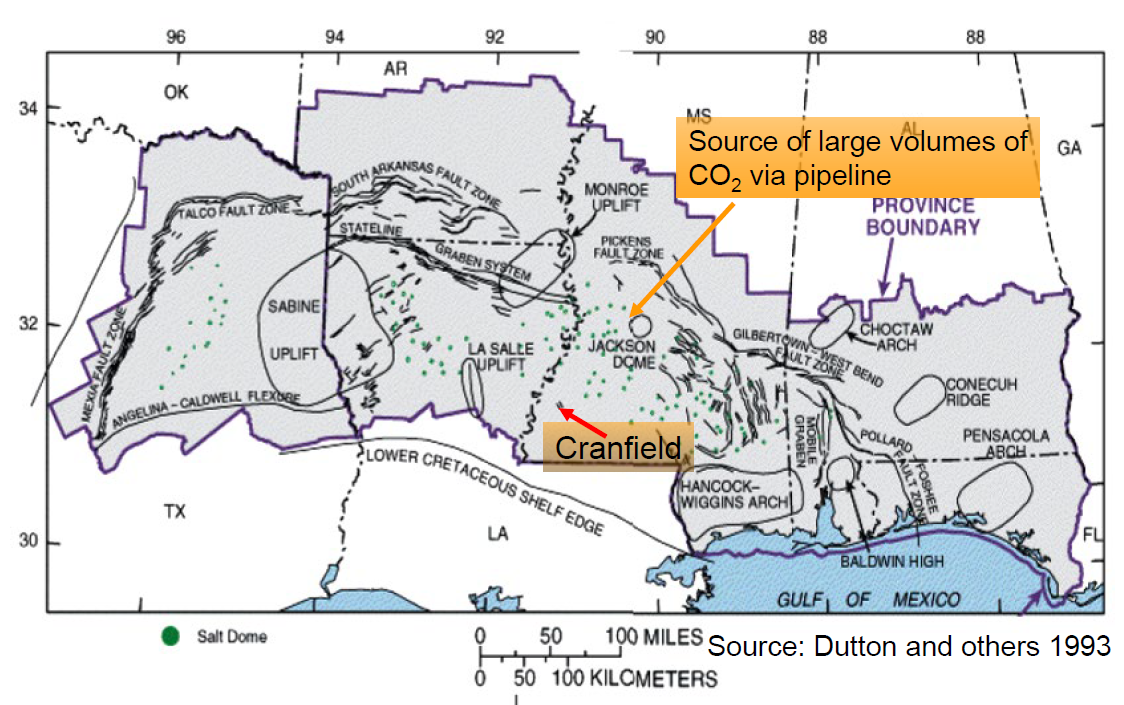

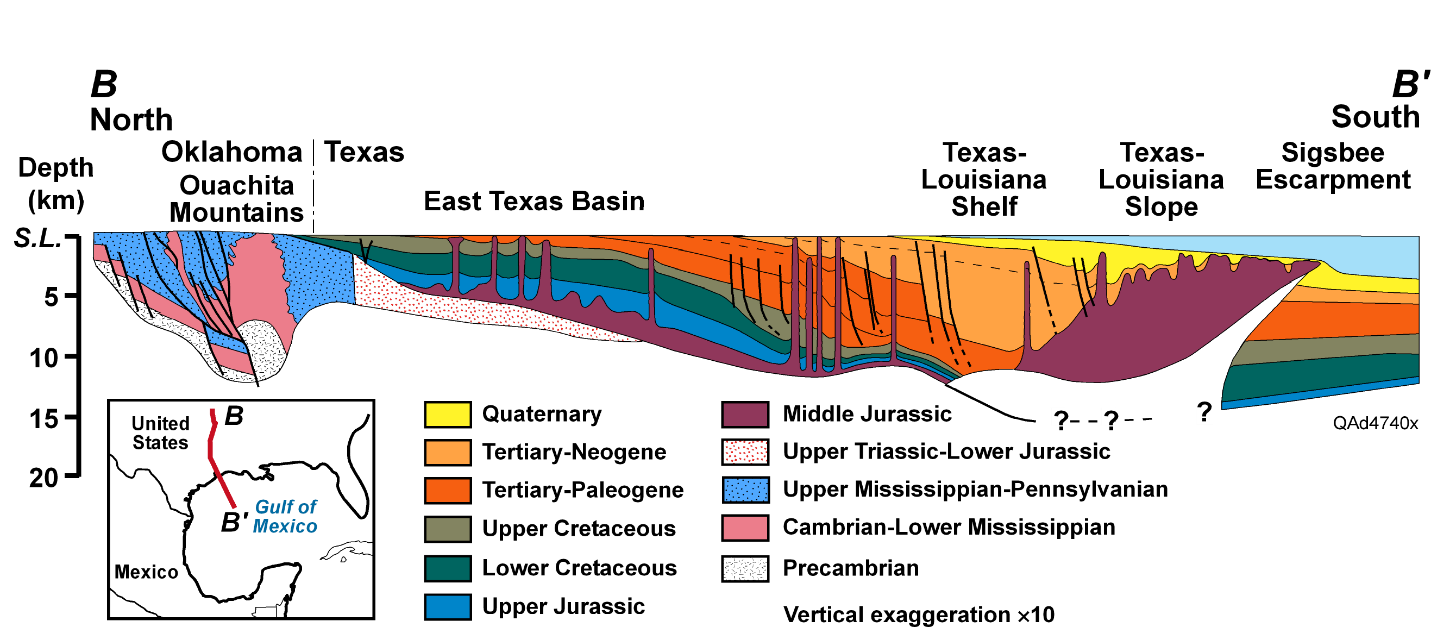

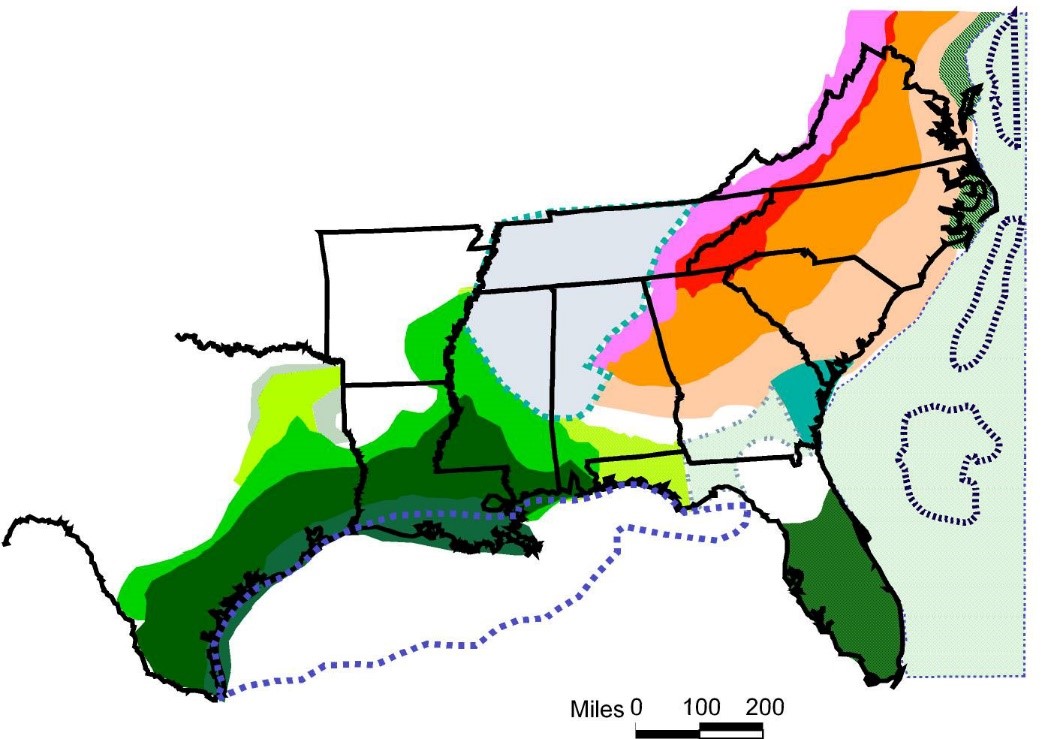

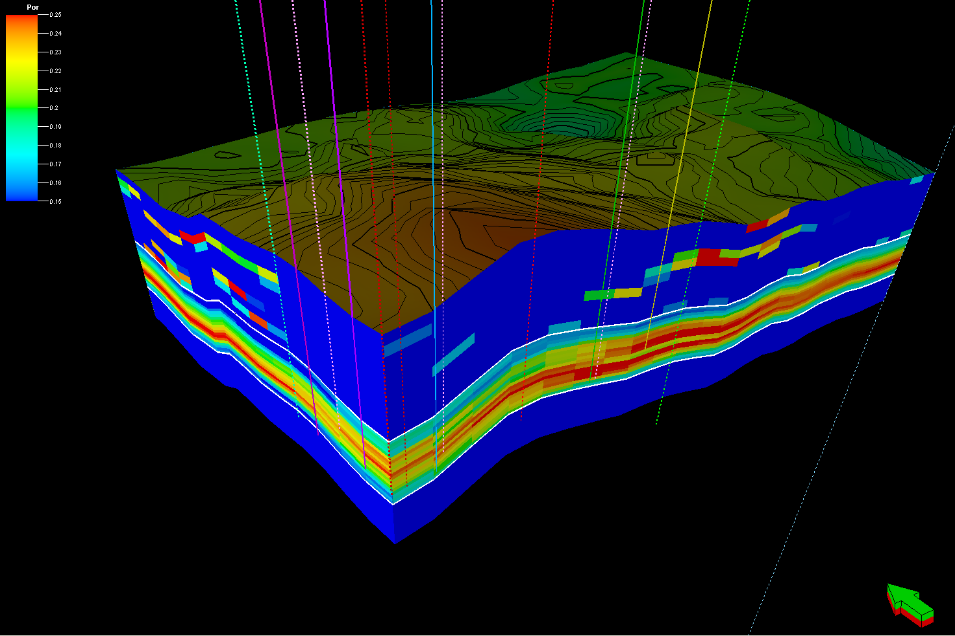

The Southeast Regional Carbon Sequestration Partnership (SECARB) team aimed to further develop storage concepts and monitoring strategies utilizing the thick sedimentary sequence of the Gulf Coast wedge sandstones with thick mudstones confining zones. Further, the team wanted to develop the concept of “stacked storage,” which unites the idea of storage associated with carbon dioxide (CO2) enhanced oil recovery (EOR) and saline storage. Twelve prospective sites were assessed in the region, and Cranfield Field was selected as an ideal site because: (1) it allowed exploration of the Tuscaloosa Formation, one of the major Cretaceous sandstone units of the Gulf Coast wedge; (2) the project host Denbury Onshore LLC was in the final stages of preparing to start a large-volume injection for EOR at this field; and (3) the operation was uniquely ideal in that the field had been idle for four decades, allowing pressure to return to near hydrostatic, enabling the SECARB team to document pressure evolution by participating in data collection at startup.

Main Research Q&As Discovered

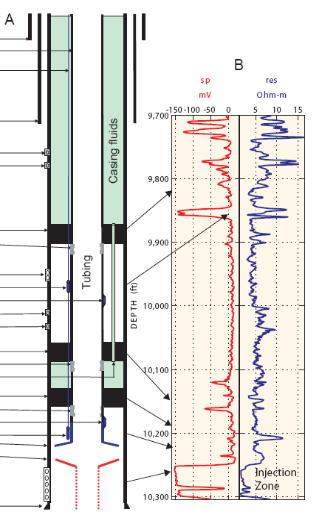

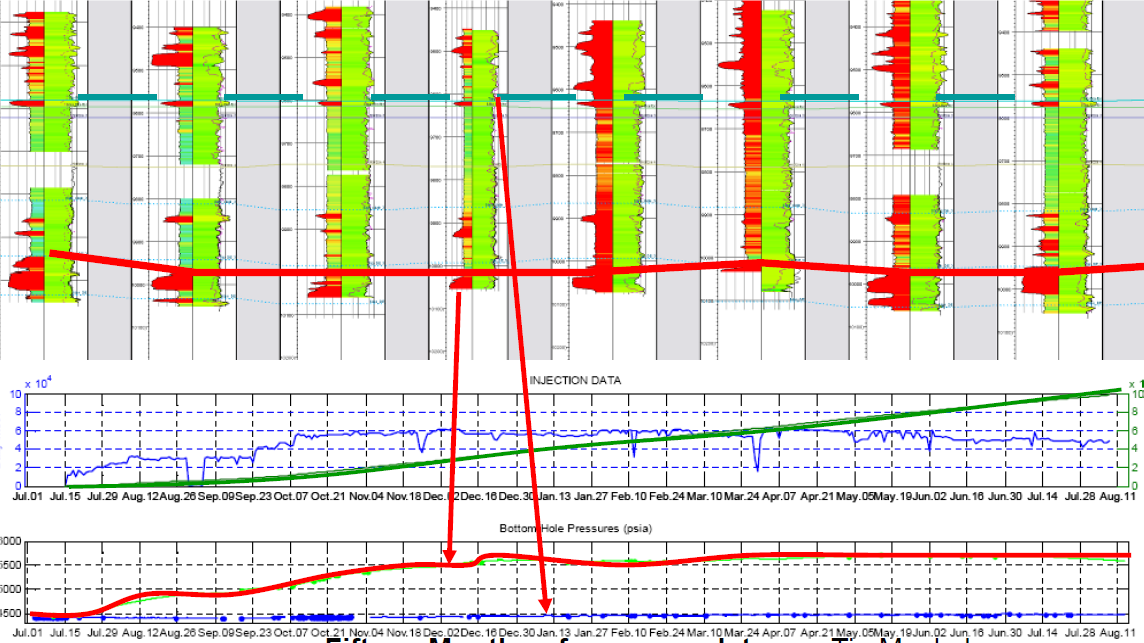

Monitoring the enhanced oil recovery (EOR) stage of stacked storage was a novel problem with far-reaching value because of the commercialization potential of carbon dioxide (CO2)-EOR for early capture projects. The team selected and developed the classic oilfield tool of pressure surveillance for the new application of documenting permanence. An existing plugged and abandoned well (Ella G Lees #7), far from initial injection wells, was re-entered and re-completed with chrome production tubing and a three-packer string to isolate the injection zone (lower Tuscaloosa zone D-E) from a selected above-zone monitoring interval (AZMI) approximately 61 meters (200 feet) shallower. Both zones were perforated, and downhole pressure gauges were installed. Pressure changes were observed in both zones.

High-frequency in-zone pressure was highly sensitive to distant operations and valuable in history-matching and interpreting reservoir response to injection (e.g., isolated versus connected compartments). Injection rate changes, especially fall-off, were highly diagnostic. Pressure change at the well-head was highly diagnostic of CO2 arrival (breakthrough) at the observation well, validating this classic breakthrough method. Comparison of wellhead and in-zone measurements and fluid density logging showed the slow breakthrough process in this site was not well-connected to injectors. Methane-enriched gas arrived before pure CO2.

AZMI pressure showed geomechanical signal in the initial stages, followed by evidence of cross-zone fluid flow at a distant pathway, validating the use of this method, which has classically been used to monitoring gas storage, but not previously for CO2 storage.

Lessons Learned

The Phase II study advanced methods for using pressure to monitor within the complex fluid of the enhanced oil recovery (EOR) setting, such that the response of the down-dip saline setting became the focus of the Phase III study; however, the Phase II observation well continued data collection. The value of pressure for documenting conformance and zonal isolation during Phase II was positive and continued to be a focus into Phase III. Well and instrument durability in these corrosive and hot environments (3 kilometers [~1.86 miles] deep) remained a problem, and the team decided to avoid the dual perforation multiple packer system during Phase III in an effort to allow repair as needed.

Public outreach managed by professional landmen working with local residents was found to be a locally accepted and beneficial method of obtaining public acceptance; project hosts were comfortable with access fees paid for monitoring activities.

Story of Interest

In an enhanced oil recovery (EOR) setting, the principle leakage risk is the integrity of pre-existing wells. Wells at Cranfield were constructed in 1943 and 1944. After production decline in the mid-1960s, most wells were plugged and abandoned (P&A). Returning the field to production using carbon dioxide (CO2)-EOR involved the operator locating, reentering, and bringing the wells back into service, which was, in general, a successful cost-reduction measure. However, the P&A well remediated to be the Southeast Regional Carbon Sequestration Partnership (SECARB) observation well had multiple problems and did not turn out to be a low-cost well. The upper part of the long string casing had been removed and had to be repaired. Heavy tubing made of recycled drilling pipe was left in the well, and multiple gas-lift mandrills required pulling out and sending down different tools to remove and then fish these elements. At the bottom of the well, the perforated zone had been weakened and partly collapsed during reentry, so a liner had to be installed in the bottom of the wells. Drilling out the bottom of the well recovered the original perforation equipment, bullets that had been shot into the casing. This well completion cost almost as much as a new well; however, fears of poor zonal isolation did not materialize. During a remedial squeeze to assure zonal isolation, the cement and other materials in the casing-rock annulus showed zonal isolation because the compartments of the well resisted circulating cement and showed pressure isolation. This experience illustrates the risk of infrastructure reuse.

Geologic Details

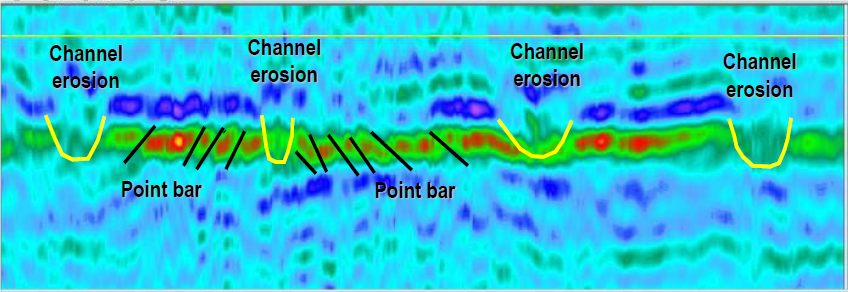

The Tuscaloosa Formation at Cranfield is a highly complex environment, both in terms of the heterogeneity of rock units and in terms of fluid occupancy. The Cretaceous lower Tuscaloosa was deposited by highly sinuous coarse-grained streams, which incised into previous channel deposits, creating an amalgamated sandstone complex with strong internal heterogeneities. Depositional heterogeneity was enhanced by diagenetic alteration, which included dissolution of volcanoclastic grains and precipitation of chlorite and quartz cements. Chlorite cement enhanced preservation of permeability at 3 kilometers (~1.86 miles) depth; however, quartz cemented zones are very low permeability.

Links to EDX

The data uploads to EDX contain commingled results from Phase II and Phase III.

SECARB Pressure Monitoring Data

doi 10.18141/1468461

Bottom-hole, above zone monitoring interval, and injection zone pressure data collected during the SECARB project in Cranfield, Mississippi to assess the relationship between pressure field and multiphase field. Submission includes 10-second interval data from Detailed Area of Study wells: CFU31-F1 (injector), CFU31-F2 (observation), CFU31-F3 (observation) and Ella G Lees no. 7 (observation) well located west of the DAS.

https://edx.netl.doe.gov/dataset/secarb-pressure-monitoring-data

SECARB Petrographic Data and Photos

doi 10.18141/1468452

Thin sections, sedimentary graphic logs, and XRD results from CFU31-F2 and CFU31-F3 wells. Data collected as part of geologic characterization phase of SECARB project at the Cranfield oilfield in southwest Mississippi. Thin sections for CFU29-12 well also included.

https://edx.netl.doe.gov/dataset/secarb-petrographic-data-and-photos

SECARB Cranfield Well Logs

doi 10.18141/1468455

Borehole logs from the SECARB project at the Cranfield oil site in Franklin, Mississippi. Well logs are a part of the geologic characterization phase of SECARB; CFU 31F-1, CFU 31F-2, CFU 31F-3 well logs from Detailed Area of Study (DAS) and other well logs.

https://edx.netl.doe.gov/dataset/secarb-cranfield-well-logs