Carbon Storage Atlas

- Why This Location

- Main Research Q&As Discovered

- Lessons Learned

- Story of Interest

- Geologic Details

- Links to EDX

- Sites

Site: Appalachian Basin – FirstEnergy’s R.E. Burger Power Plant, Shadyside, Ohio

Lat/Long

Belmont County, Ohio

Appalachian Basin R.E. Burger Power Plant: 39.910716, -80.763165

Why this Location?

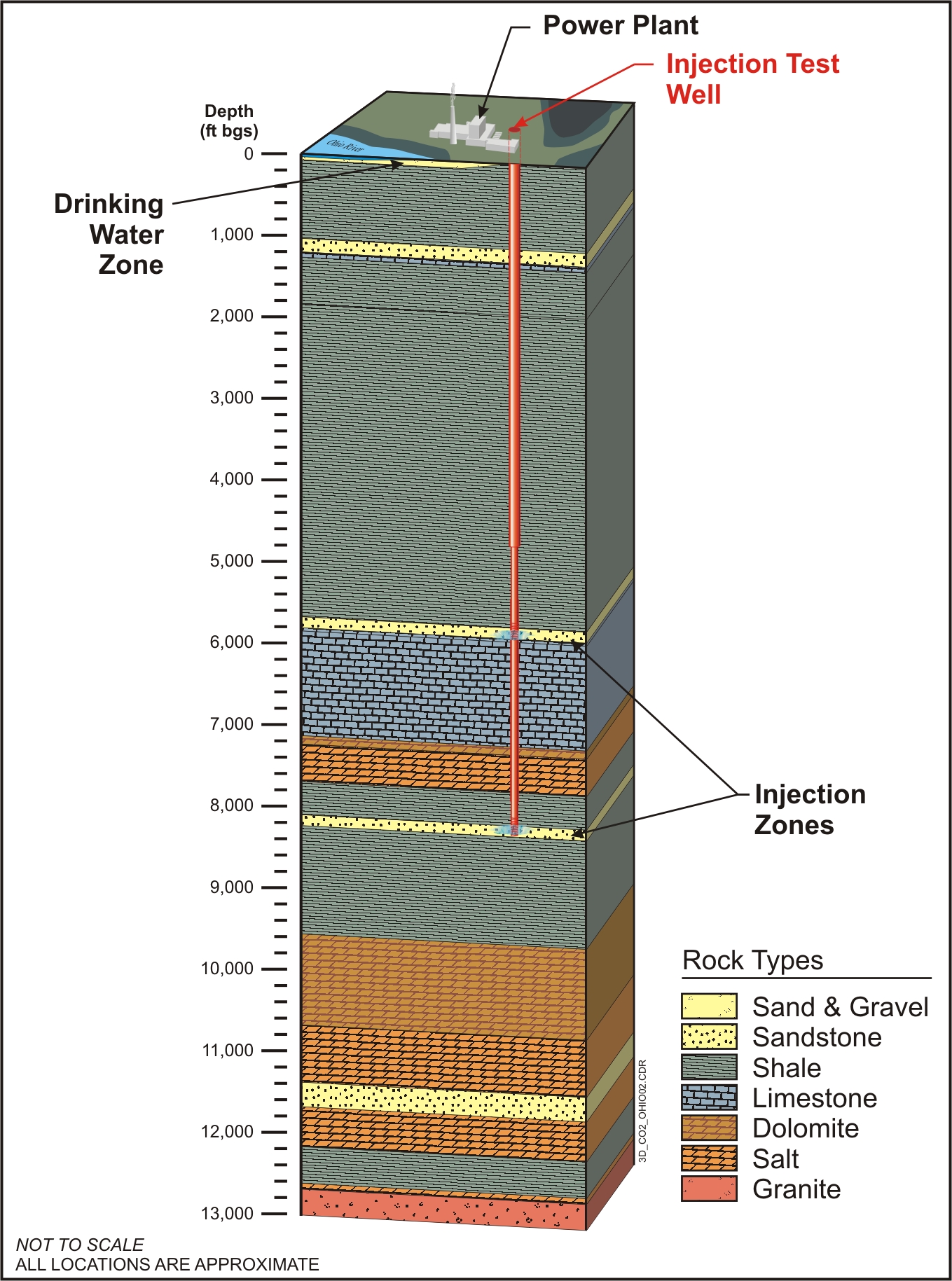

This field site location was selected because of its central location in the Appalachian Basin and close proximity to the Upper Ohio River Valley Power Corridor, which has nearly 20,000 megawatts of coal-fired capacity in the region. Additionally, the site had projected storage potential in the Oriskany and Clinton Sandstones, which are pervasive in the region. The site also benefited from the close proximity to the Burger Plant and willingness of the host company, FirstEnergy, to provide site access.

Main Research Q&As Discovered

The main objectives of this test site were to explore geologic storage targets in this area of the Appalachian Basin, to develop carbon dioxide (CO2) storage technology through drilling of a deep test well, and to conduct CO2 injection tests. Through the collection of sidewall cores and wireline logs, three injection zones were identified: the Oriskany Sandstone, Middle Salina Carbonate, and Clinton/Medina Sandstone. Hydraulic tests were conducted, which indicated that high-injection pressures would be needed for these formations due to low permeability. While 3,000 metric tons was planned for injection, less than 100 metric tons injection was possible due to limited injectivity.

Lessons Learned

This site was the first “dry well” encountered within the U.S. Department of Energy’s (DOE) Regional Carbon Sequestration Partnership (RCSP). Although injectivity at this site was less than expected, the test did help establish familiarity with carbon dioxide (CO2) storage technologies in the region and provided an important deep well data point in a strategically valuable portion of the Midwest Regional Carbon Sequestration Partnership (MRCSP) region. The test also highlighted the variability of geologic environments, especially in the geologically deep and complex Appalachian Basin. The Burger test described here, as well as the other two MRCSP Phase II tests, showed that characterization methods (rock core tests, wireline logging, and geologic logging) may only provide indicators of injectivity. True injection potential needs to be proven with field injection tests. The Burger site highlights the value of these smaller, research-oriented tests, which allow valuable experience to be gained in site characterization, permitting, infrastructure implementation, and injection testing with significantly less capital investment compared to full-scale application. The negative finding in this well led to a more detailed storage potential assessment in Ohio’s Appalachian Basin, resulting in the emphasis on dolomitic vuggy carbonates as a primary storage target in deep mature basins. It also allowed the host company to determine an alternate future for the plant rather than installing a capture system at that time.

Story of Interest

When Scientists Meet Oil and Gas

The current state of carbon capture and storage (CCS) projects requires collaboration between scientists and oil and gas workers. The project at FirstEnergy’s Burger Power Plant started out with quite a few blank stares when plans were provided by the drilling company for the installation of the injection well, or when Battelle had plans to stop drilling so some “crazy” sample could be collected. By the end of the field effort, all sides had migrated to a middle ground of thought and the entire group had changed with an understanding and appreciation for what was trying to be accomplished. The following are just a few examples of understanding that came about through the process:

The oil crews realized that:

- “Making hole” as quickly as possible was not the objective and sometimes they needed to sit on their hands while characterization was taking place. Also, these slow periods provided an opportunity for fishing at the pond just off location or spotting deer from the derrick.

- Battelle was willing to pass up great oil and gas zones to get to some geologic formation that just held brine.

- They really are not allowed to work through a thunderstorm

Battelle realized that:

- The oil and gas crews really know quite a bit about geology and fluid flow, even though the crew members never took a college course in these subjects, and they help the project migrate through complicated issues.

- Sometimes there is no known tool to collect the samples that are needed; something would need to be custom made to do that.

- Yes, you can feed 20 people for $10 with a little salsa, mystery meat, and a slow cooker.

Geologic Details

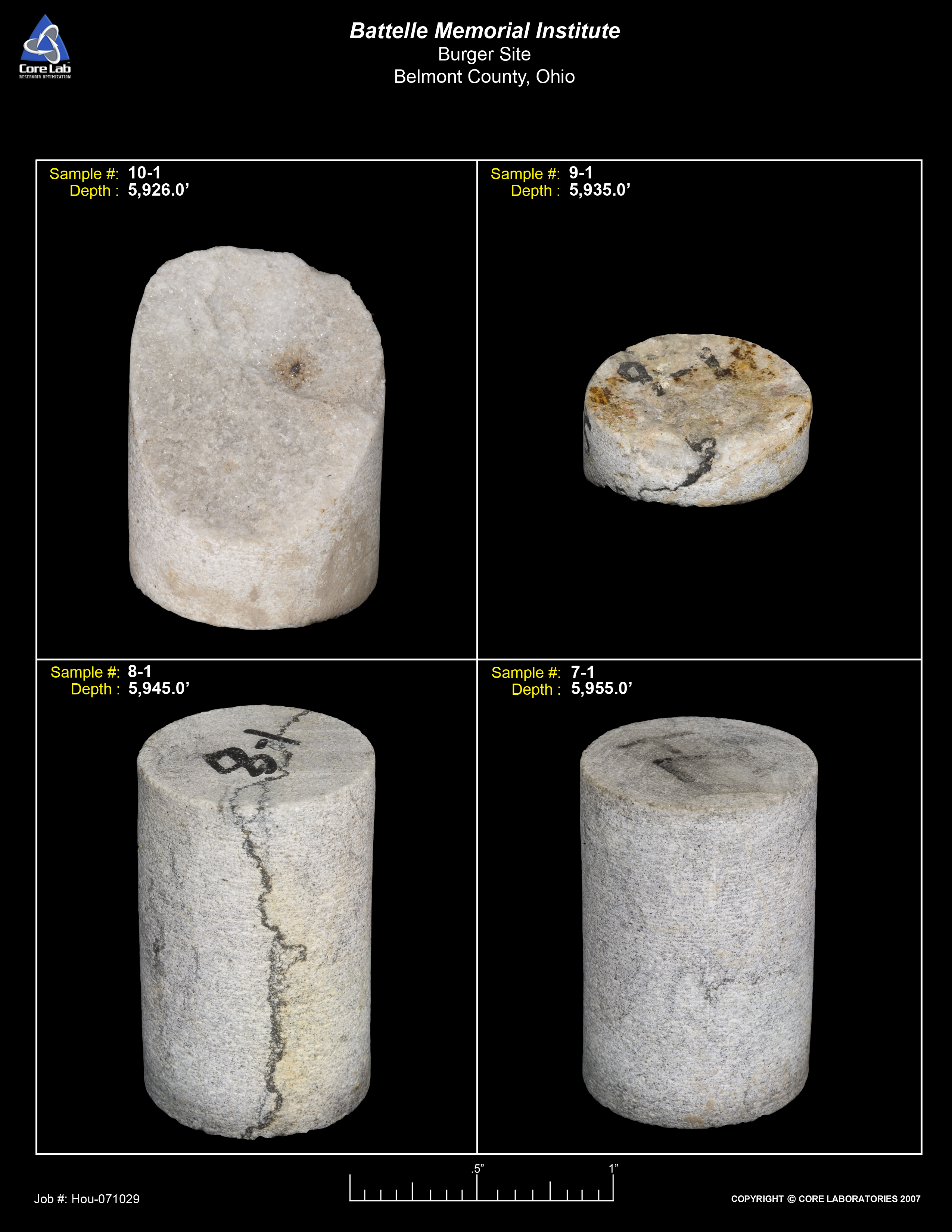

A full program of mud logging, wireline logging, sidewall coring, core testing, and petrophysical analysis was completed to characterize the geologic units. This information was used to identify three injection targets, define confining layers, and plan injection testing. Wireline logs showed zones of porosity between 2 and 10% within the key injection targets. Core samples were tested for porosity, permeability, mineralogy, and density, with standard procedures showing porosity less than 5% and permeability less than 1 millidarcy (mD) for most of the cores. The injection testing provided valuable information on field operations and well test data, showing rapidly declining injection rates when pressure was sustained at specific values.