Carbon Storage Atlas

- Why this Location

- Main Research Q&As Discovered

- Advice for Future Operators

- Geologic Details

- Project Introduction and Site Operations

- Site Characterization

- Risk Assessment

- MVA

- Stakeholder Engagement

- Sites

Lat/Long

-88.893410, 39.876963

Why this Location

During Phase I and Phase II, the Midwest Geological Sequestration Consortium (MGSC) identified potential carbon dioxide (CO2) sources in the region. MGSC’s Phase II enhanced oil recovery (EOR) and enhanced coalbed methane (ECBM) projects used trucked-in CO2. Because MGSC decided to increase the size of the original Phase II saline project to a large-scale project, they needed to find alternatives to trucking CO2. Rob Finley, the original Principal Investigator for MGSC, approached Archer Daniels Midland (ADM) Company as a potential source to buy CO2. The initial intent was to buy CO2 from ADM and either truck it or build the pipeline to somewhere south of Decatur, Illinois. ADM is very engaged in research, development, and demonstration (RD&D) in Decatur, and at the time had a new CEO who was very interested in environmental technologies, climate change mitigation, and risk. She recognized the potential benefits of capturing CO2 from ethanol production, so ADM offered a project site that made the Illinois Basin – Decatur Project (IBDP) possible and created a long-lasting partnership responsible for storing more than 2.7 million metric tons (as of April 2020) as part of two projects (IBDP and the Illinois Industrial Carbon Capture and Storage Project [IL-ICCS]) at the ADM site.

Main Research Q&As Discovered

There were three main research questions for the Illinois Basin – Decatur Project (IBDP):

-

Could the Midwest Geological Sequestration Consortium (MGSC) safely and effectively demonstrate the full carbon capture, utilization, and storage (CCUS) value chain in a saline reservoir?

-

Could MGSC demonstrate injectivity and containment within the Mt. Simon Sandstone and Eau Claire Shale storage complex at the site?

-

Could MGSC demonstrate, using monitoring technologies, that the activities were protective of human health and safety and environmental safety?”

MGSC fully demonstrated, from start to finish, the value chain of carbon capture and storage (CCS) in a saline reservoir in conjunction with biofuel production at Archer Daniels Midland (ADM), with construction of an above-ground pipeline and storage of carbon dioxide (CO2) at more than 7,000 feet beneath the subsurface at the IBDP site. A comprehensive deep, shallow, and near-surface environmental monitoring program substantiated the finding that there are no out-of-bounds environmental conditions—indicative of no leakage of CO2 from the storage complex.

Advice for Future Operators

Future operations would benefit from the integration of monitoring with existing systems. For example, the Illinois Basin – Decatur Project (IBDP) monitoring data stream (e.g., real-time information on injection operations and downhole conditions in the observation well, the injection well, and the geophone-equipped seismic monitoring well) goes into the supervisory control and data acquisition (SCADA) system, which is the data system Archer Daniels Midland (ADM) Company uses to run their entire plant. Future operators would benefit from an early consideration of the surface infrastructure footprint, from working with people who have experience in injection operations, and from interfacing injection/monitoring operations with existing plant infrastructure.

Geologic Details

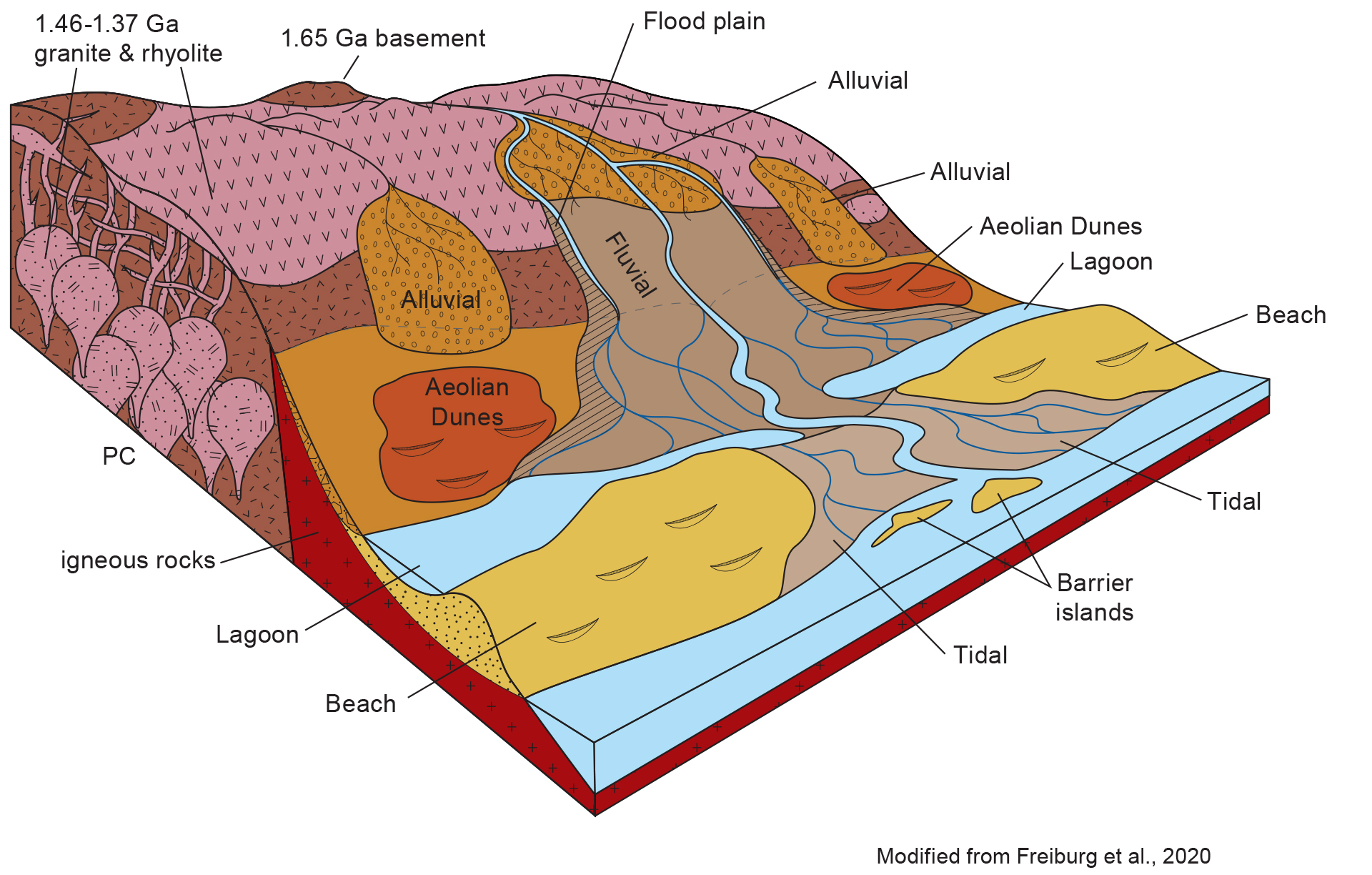

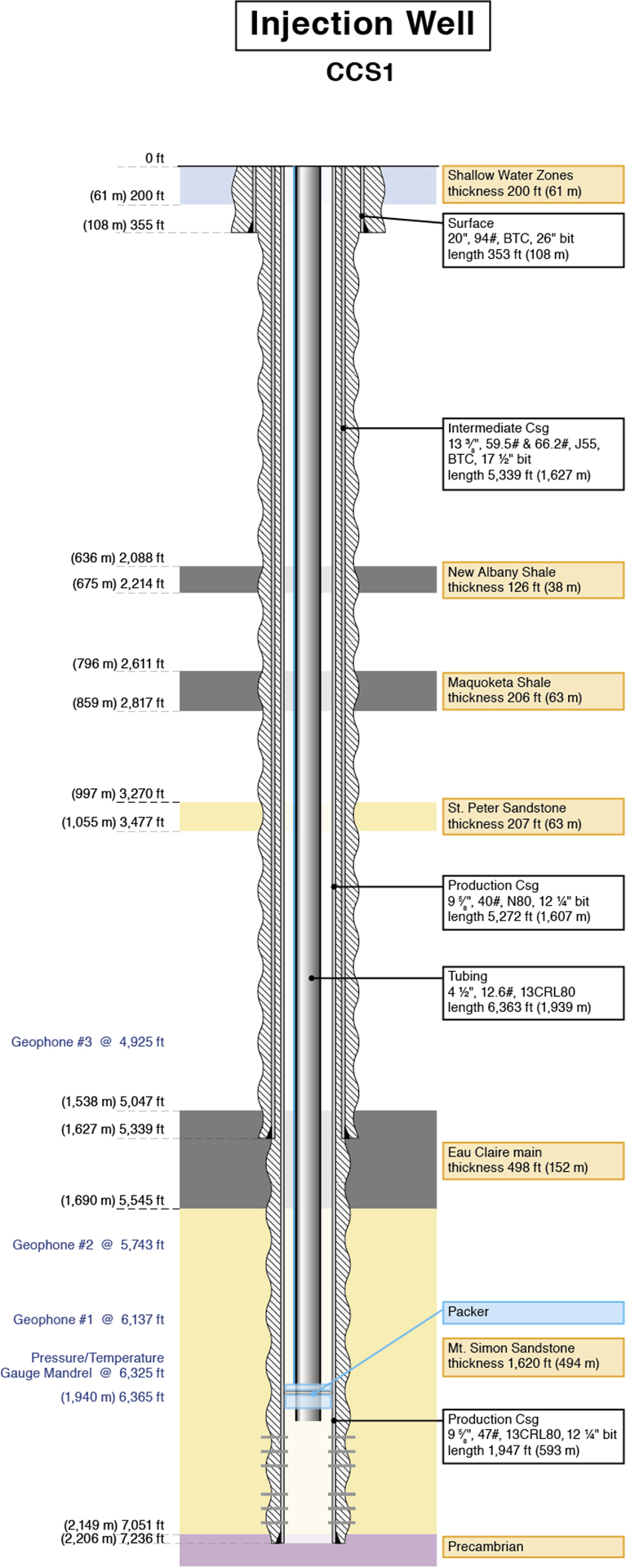

The thickest and most widespread saline reservoir in the Illinois Basin is the Cambrian-age Mt. Simon Sandstone. It is overlain by the Cambrian Eau Claire formation, a regionally extensive, low-permeability unit of shale and other lithologies. The Mt. Simon Sandstone is underlain by Precambrian igneous basement rock.

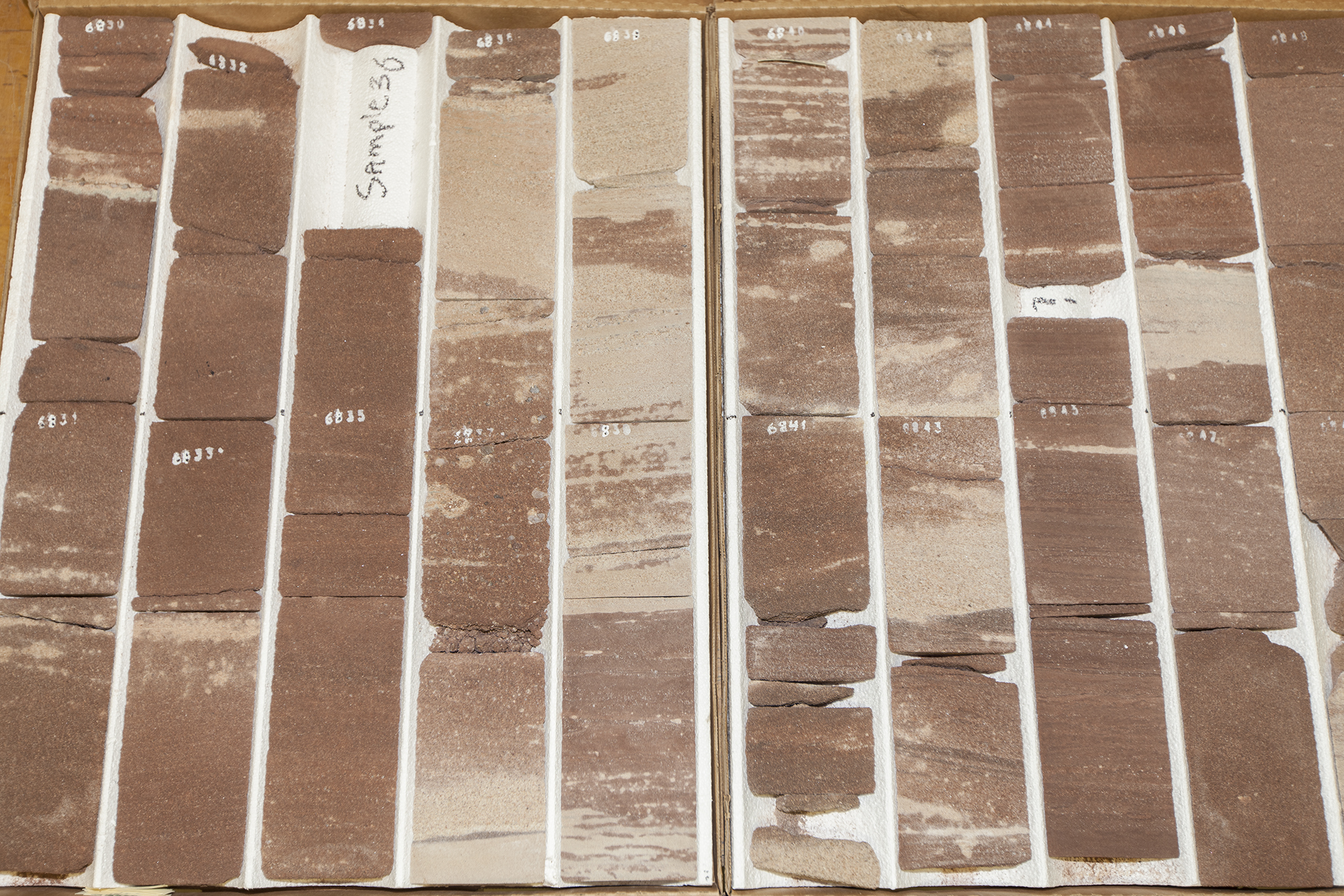

The deposition of the Mt. Simon Sandstone is commonly interpreted to be a shallow marine to deltaic environment with thick braid plain sequences. At the Illinois Basin – Decatur Project (IBDP) site, the upper part of the Mt. Simon Sandstone is comprised of interbedded quartz arenite and mudstone that is interpreted to have been deposited in a tidally influenced system. This upper portion of the Mt. Simon Sandstone is a reservoir for natural gas storage in central and northern Illinois. The basal 183 meters (600 feet) of the Mt. Simon Sandstone is largely comprised of arkosic sandstone that was originally deposited in a fluctuating fluvial-eolian system with possible influence of a nearshore beach environment. The lower Mt. Simon Sandstone is the principal target reservoir for storage due to its anomalously high porosity resulting from diagenesis of feldspar grains forming abundant amounts of secondary porosity.

In general, the paleogeography of Illinois at the time of Mt. Simon Sandstone deposition was one of a low-relief subsiding basin that was open to the ocean to the south. At IBDP, the lower-most Mt. Simon Sandstone unconformably lies on about 36 meters (110 feet) of low porosity and permeability sandstone and conglomerate referred to as the Argenta Unit, which in turn rests on the rhyolitic Precambrian basement.

Project Introduction and Site Operations

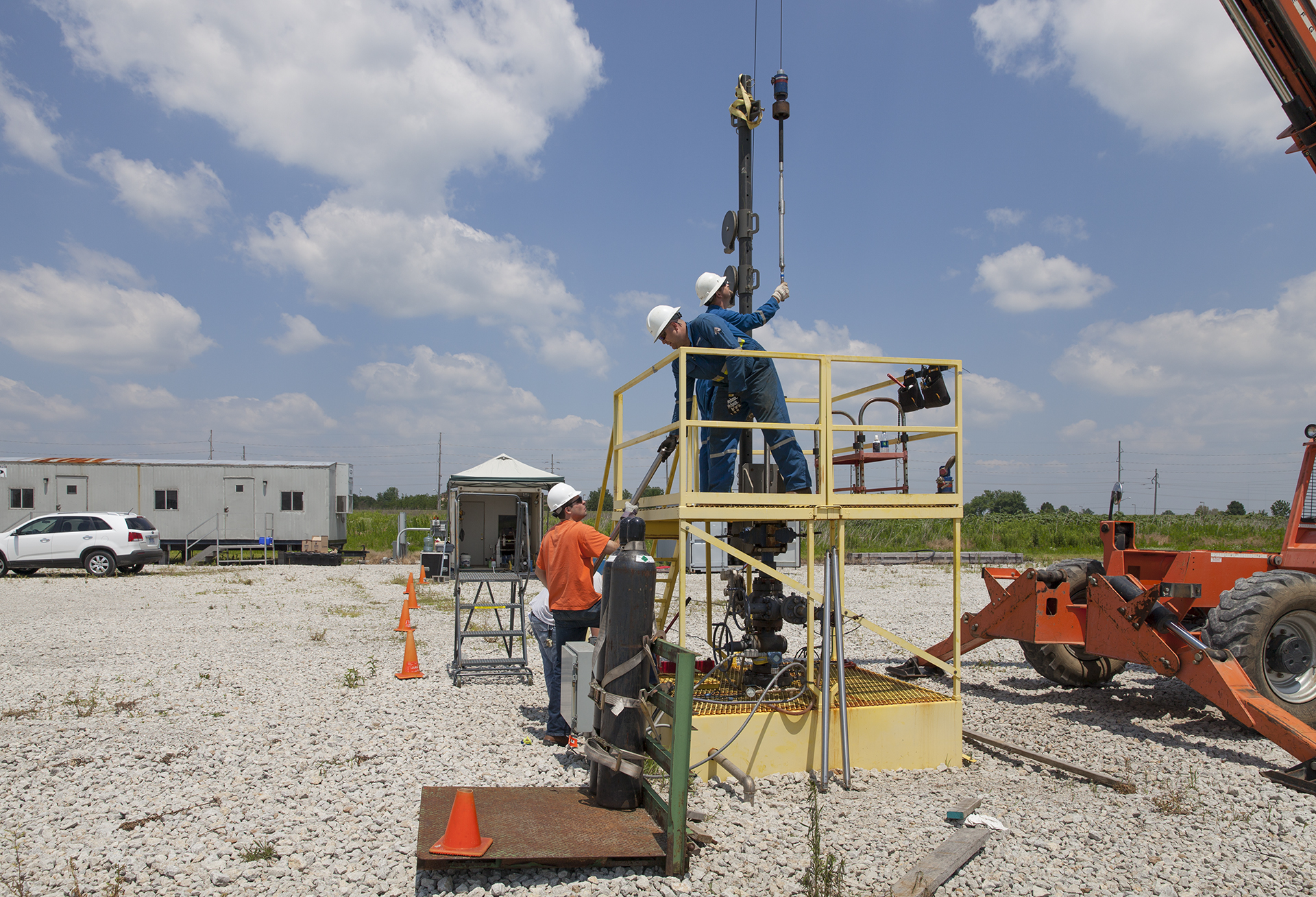

The Midwest Geological Sequestration Consortium’s (MGSC) Illinois Basin – Decatur Project (IBDP) is a collaboration of MGSC, Archer Daniels Midland (ADM) Company, Schlumberger Carbon Services, Trimeric, and other subcontractors to inject 1 million metric tons of anthropogenic carbon dioxide (CO2) into a saline reservoir, the Mt. Simon Sandstone, in Decatur, Illinois. Operational CO2 injection began on November 17, 2011, at a nominal rate of 1,000 metric tons per day. After three years of operations, the injection goal was met in November 2014. Capacity, injectivity, and containment potential have met and/or exceeded pre-injection expectations.

The Mt. Simon Sandstone represents the primary CO2 storage resource in the Illinois Basin and the Midwest region and is more than 457 meters (1,500 feet) thick at the IBDP site. The upper portion was deposited in a tidally influenced system, while the lower 183 meters (600 feet) is an arkosic sandstone that was deposited in a braided river/alluvial fan system. The lower Mt. Simon Sandstone is the principal target for storage, in part because the dissolution of feldspar grains has created good secondary porosity. The Eau Claire Formation is the primary confining layer, or seal, and is 212 meters (695 feet) thick. The lower Eau Claire consists of shale and the upper unit consists of low-permeability limestone and siltstone.

IBDP is unique in that it was the world’s first bioenergy carbon capture and storage (BECCS) project, an integrated industrial CCS system from source to reservoir. The project used CO2 from ADM’s ethanol fermentation process. Operations consisted of a compression/dehydration facility, a delivery pipeline, one injection well, one deep observation/verification well, a geophysical test well, and an integrated environmental monitoring system, all developed on the ADM-owned site.

The real-time acquisition and control (RTAC) and Well Watcher Connect systems were specifically created to provide continuous subsurface project data, such as wellhead pressure and temperature, downhole pressure and temperature, and annulus pressure, which is critical to operational monitoring. This data was recorded, archived, and continuously accessible. The software recorded and formatted pressure, temperature, annulus pressure, and injected volumes as required for permit reporting.

Site operations at IBDP were administered through the RTAC software. This real-time monitoring provided increased operational safety, as RTAC collected vast amounts of data on a high-frequency basis and provided a secure Internet site for project personnel to access real-time information on injection operations and downhole conditions in the observation well, the injection well, and the geophone-equipped seismic monitoring well.

Why is the Illinois Basin – Decatur Project Unique?

Injection Operations

Injection rate: 1,000 metric tons of CO2per day at a single well, CCS1.

Total injection: 999,215 metric tons of CO2 from November 17, 2011, through November 26, 2014.

Well Construction

Surface Delivery Pipeline: 15.24-centimeter (6-inch) carbon steel, length of 1.9 kilometers (1.2 miles).

Downhole Tubing: 11.43-centimeter (4.5-inch), 13Cr-L80, length of 1,939.4 meters (6,363 feet).

Well Total Depth: 2,205.5 meters (7,236 feet).

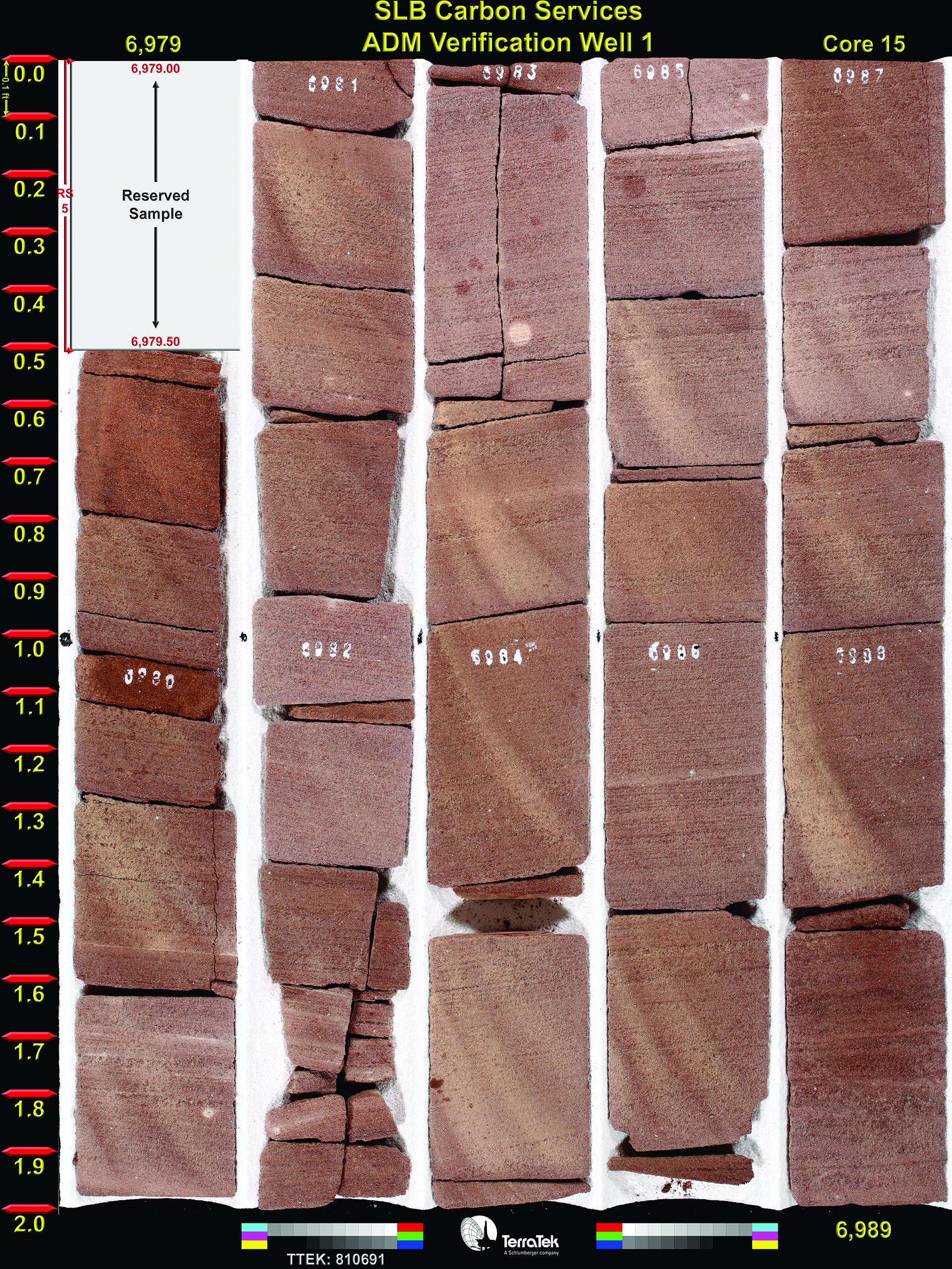

Depth of Injection Interval: 2,129.6 – 2,149.4 meters (6,985 – 7,050 feet).

Site Characterization

The injection formation and primary seal are extremely well characterized at the Illinois Basin – Decatur Project (IBDP) site. Based on the well log and core analyses and interpretation of the injection and verification wells, the Mt. Simon storage complex and Eau Claire seal have been thoroughly characterized at the IBDP site. Between the injection and verification wells, almost 213 meters (700 feet) of whole core and more than 125 sidewall rotary core samples were acquired. A short-term pressure transient test was conducted to confirm the core-log permeability transform. Several publications (Freiburg et al., 2016; Leetaru & Freiburg, 2014) have examined the geology, depositional systems, and diagenetic history. As with all subsurface characterization, the spatial representation of the detailed characterization at each well bore is the challenge. Seismic characterization includes 2D, 3D, and vertical seismic profile (VSP) acquired to improve the understanding between wells and are the basis for several geostatistically generated geologic models of the site. Coherence interpretation of the 3D surface data has shown details of internal reservoir depositional heterogeneity, such as channel forms within the Mt. Simon Sandstone. The 4D surface seismic data are being used to further characterize the reservoir and understand reservoir pressure response to injected carbon dioxide (CO2).

Validated Technologies

The monitoring, verification, and accounting (MVA) program has served as an effective testing ground for technology/deployment validation. Some of these technologies include:

-

Westbay®: The deepest Westbay installation in the world was installed to 2,100 meters (7,000 feet), with nine zones into the Mt Simon Sandstone and overlying Eau Claire Shale. Over the course of approximately six years of deployment (roughly June 2011 to May 2017) and 11 sampling rounds that yielded 103 samples, a detailed sampling procedure was developed, which led to a comprehensive pre-injection deep brine characterization data set and validation/adjustment of geochemical modeling inputs.

-

Interferometric Synthetic Aperture Radar (InSAR): InSAR was deployed at the IBDP site to detect surface deformation monitoring. InSAR had been implemented effectively in the In Salah CO2 Storage Project in central Algeria. Comparatively, the IBDP site provided an opportunity to test the technology in an area with increased surface vegetation, which has the potential to hinder accurate displacement detection. An array of radar targets was installed at IBDP to compensate for increased vegetation and improve measurement of surface displacement. Periods of vegetative overgrowth has impacted signal return, requiring physical removal of vegetation, helping to refine InSAR techniques for sites with more extensive ground cover.

-

Greenhouse Gas Laser Imaging Tomography Experiment (GreenLITE): The GreenLITE system uses laser absorption spectroscopy to measure the 2D spatial distribution of atmospheric CO2 concentrations over areas between 1 and 30 square kilometers (~0.39 and 11.6 square miles) for use in MVA programs at carbon capture and storage (CCS) sites. The GreenLITE system was deployed at the IBDP site to demonstrate autonomous operation of the system in a real-world CCS environment over an extended period and under a wide range of operating conditions. With minimal human intervention following installation, this technology demonstrated a cost-effective, reliable method of monitoring CO2 leakage at large-scale CCS sites.

How the Illinois Basin – Decatur Project is Advancing CCS Technologies

Passive and active seismic monitoring have been ongoing at the IBDP site. Microseismic monitoring began well before injection started (approximately 1.5 years prior to the three-year injection) and continues to the present day for IBDP and a second project at Archer Daniels Midland (ADM). The system is designed to observe microseismicity (magnitude 2 or below events), a potential outcome in the subsurface at CO2 injection projects. Locatable microseismic events started two months after injection, with an average of approximately four locatable events per day during injection. These microseismic events began to form a series of elongate cluster pattern that occur in lower Mt. Simon Sandstone, pre-Mt. Simon Sandstone (Argenta), and top of the Precambrian in conjunction with the regional stress, and give an indication that Precambrian basement faults could be reactivated. The IBDP has the most comprehensive set of reservoir observations of microseismic activity associated with carbon storage. The ability to understand microseismicity is a major continuing research interest and the unique IBDP data set will contribute to the global understanding of microseismic activity related to CO2 injection and storage.

Risk Assessment

The Illinois Basin – Decatur Project (IBDP) risk management approach has been an evolving cycle of risk identification, assessment, evaluation, and treatment, with two constant objectives: (1) ensure that risks are identified and (2) ensure that all identified risks are reduced and/or held to acceptable levels. Three formal risk workshops (two pre-injection in 2008 and one in 2013), as well as an abbreviated risk workshop (December 2016), were conducted, focusing on plans and treatments for risks associated with technical challenges, health and safety, budget, and public interactions. Pre-injection risk looked at identification of features, events, and processes (FEPs) and scenarios, and addressed geologic, operational, regulatory, and social uncertainty. The risk profile has notably (though unsurprisingly) changed as the project has progressed from pre-injection to the current post-injection site care (PISC), leading to closure of the site and project.

Key findings included:

-

Establishment of project data baseline is critical to site characterization and reduction of project risk, but regular revision is needed.

-

Permitting can be time-intensive and should not be underestimated as a potential project risk.

-

Knowledge sharing is a vital element to a successful project.

Simulation and Modeling

IBDP modeling efforts were an iterative process of model improvements through the integration of 3D seismic, petrophysical, and borehole data, with the objective of developing the capability to perform consistent reservoir engineering and mechanical forecasting within a representative geological context.

Geologic Model: Static geological model development consisted of: (1) defining the structural/stratigraphic framework through regional mapping and integration of 3D seismic data with mapped stratigraphic horizons, and (2) populating the geologic model with data from geophysical log data, rock petrophysical properties, and 3D seismic data.

Reservoir Engineering Model: This dynamic model derived geologic framework from the geologic model and was used to perform forecasts of pressure and saturation for injection scenarios. The IBDP monitoring program includes real-time continuous measurement of rate, pressure, and temperature data at the injector, as well as measurements of carbon dioxide (CO2) saturations computed through repeated wireline reservoir saturation tool logging campaigns in the injector and the verification well.

Geochemical Modeling: IBDP geochemical modeling focused on the reservoir and the shallow groundwater aquifers. Reservoir-based modeling evaluated potential reactions between CO2-saturated brine and the reservoir. In the Mt. Simon Sandstone modeling, the total amount of reactivity was limited by the high amounts of quartz in the system and general slow kinetics of silicate mineral reactions. Batch experiments were conducted on reservoir materials and models to provide estimates of the kinetics of reservoir and confining layer mineral alteration and potential trace metal release. The shallow modeling examined the potential impacts to shallow groundwater systems in response to a CO2 leakage and the sensitivity of chemical parameters established through baseline data analysis of shallow groundwater samples taken from research and compliance wells, along with X-ray diffraction (XRD) analysis of shallow well cores, to the simulated addition of CO2.

Geomechanical Modeling: The geomechanical modeling workflow had two steps:

-

The integration of available geomechanical data to create the mechanical earth model (MEM). The IBDP geomechanical program included extensive mechanical characterization in three wells through acquisition and analysis of both core and specialized wireline logs, as well as through field testing.

-

Input MEM to a dynamic geomechanical simulator (Visage*) for forecasting projected stress paths at selected locations in the wellbore and reservoir for hypothetical injection scenarios.

The Midwest Geological Sequestration Consortium (MGSC) modeling has developed a basin-scale, multi-phase flow model of the Mt. Simon Sandstone for the Illinois Basin that covers most of Illinois and Indiana, which simulates fluid migration and pressure increases in the Mt. Simon Sandstone, pre-Mt. Simon Sandstone (Argenta), and Eau Claire formations, resulting from commercial-scale geologic carbon storage.

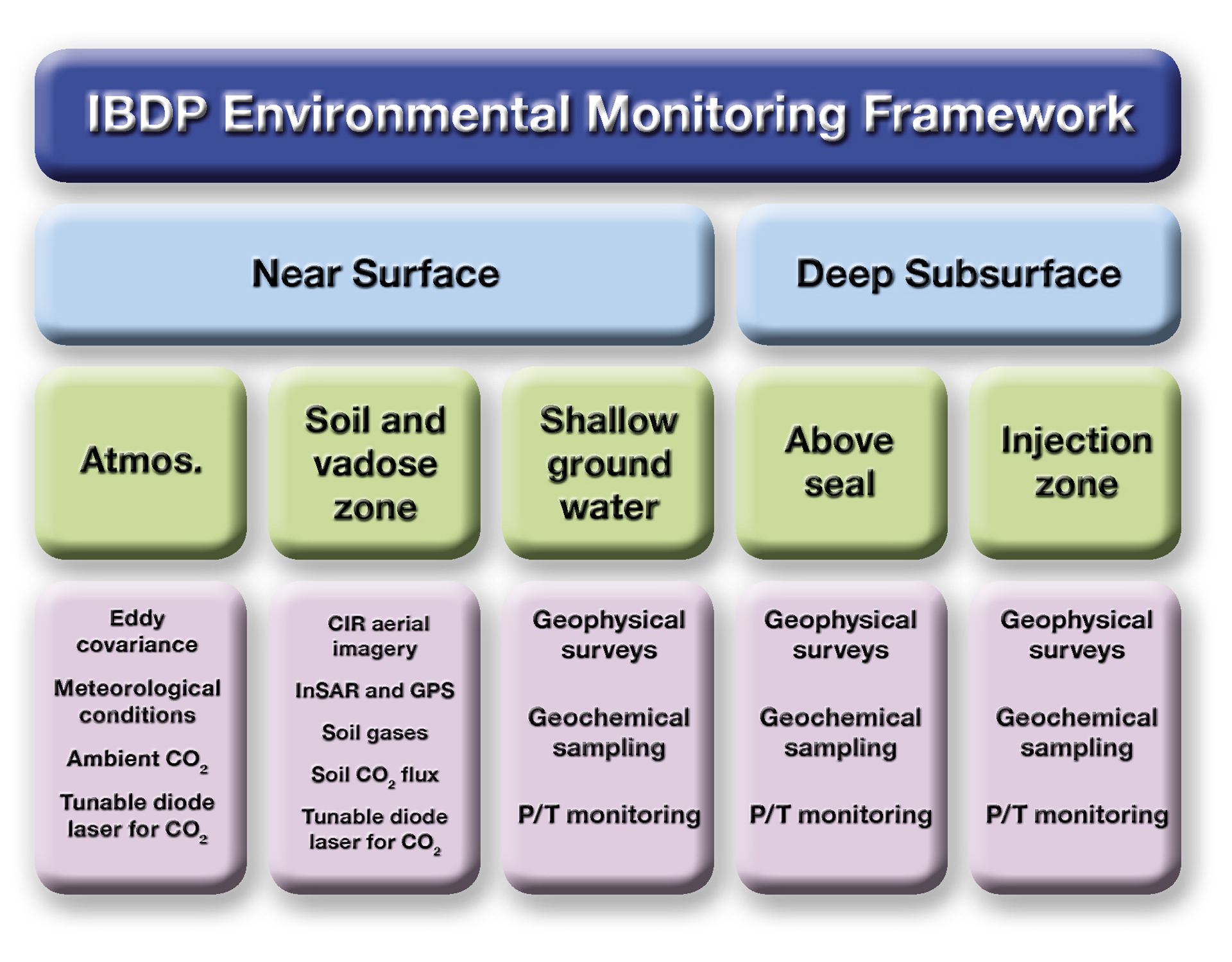

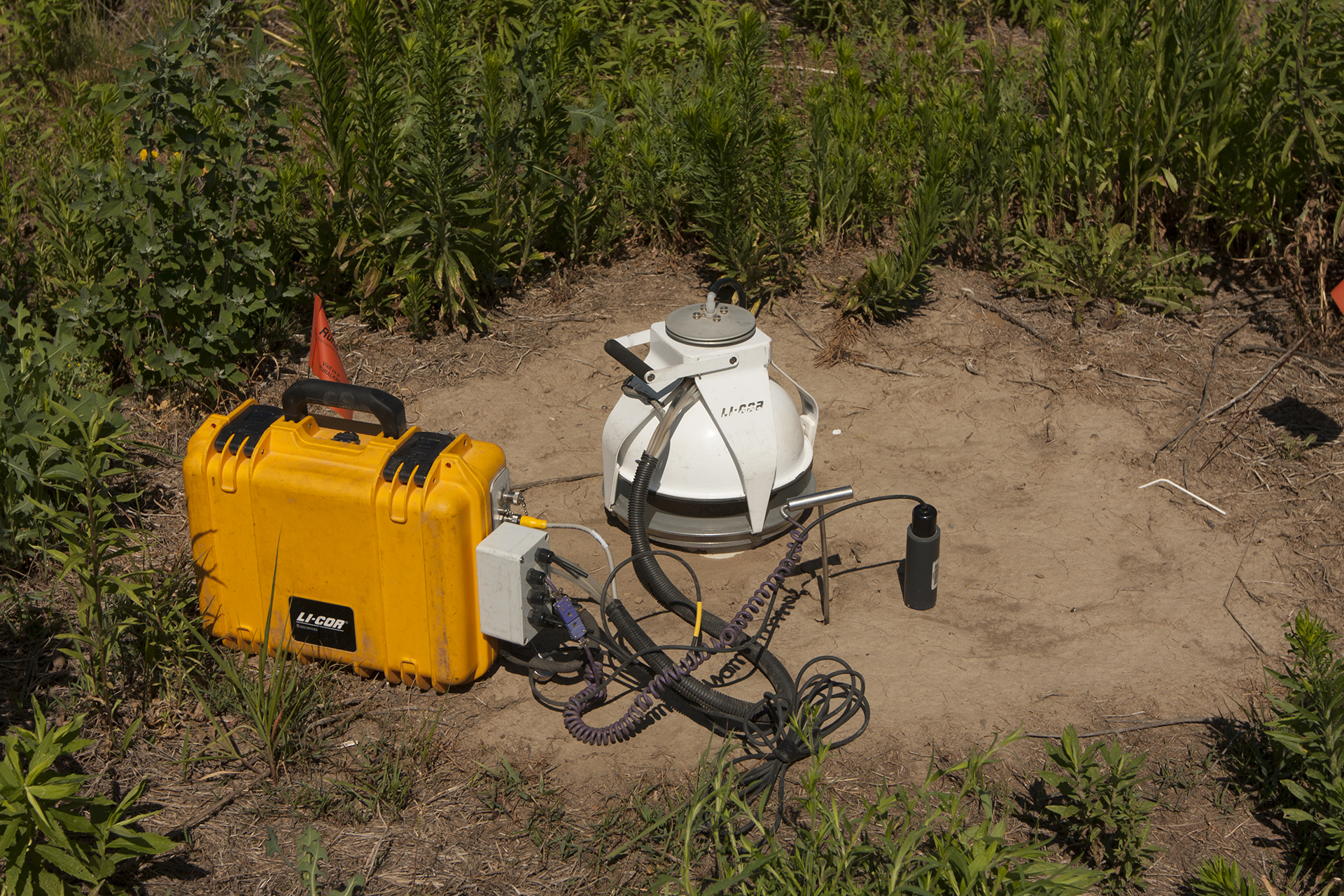

MVA

An extensive environmental monitoring, verification, and accounting (MVA) program was developed for the Illinois Basin – Decatur Project (IBDP), with the objectives of establishing baseline conditions to assess potential impacts from carbon dioxide (CO2) injection, demonstrating project activities are protective of human health and the environment, and providing an accurate accounting of stored CO2 during and after injection operations. The research monitoring program was initiated in 2008, allowing for up to 36 months of pre-injection baseline data acquisition. Since November 2014, the project has been in the post-injection site care (PISC) phase, with monitoring intensity significantly decreased in fall 2015. The PISC monitoring activities have been optimized to address the IBDP injection well (CCS1) Class VI permit conditions and are scheduled to continue through April 2021. The MVA program at IBDP is a collaborative effort in which more than 20 different near-surface and subsurface monitoring methods were tested throughout each of the project phases for their efficacy in monitoring large-scale carbon capture and storage (CCS) projects.

Monitoring of the near-surface environment includes high-resolution electrical earth resistivity, color aerial imagery, interferometric synthetic aperture radar (InSAR), continuous global positioning system (GPS), laser absorption spectrometer systems, shallow groundwater quality, soil CO2 fluxes, net-exchange CO2 fluxes, and vadose zone CO2 concentrations. Although many of the techniques implemented at the IBDP site have ceased and the installations have been removed, an optimized shallow groundwater monitoring program is active. Environmental monitoring data have shown no signs of CO2 release.

Subsurface monitoring efforts include 2D seismic, 3D seismic, and repeat vertical seismic profiles (VSPs); passive microseismic monitoring; injection zone temperature, pressure, and fluid monitoring; above-caprock temperature, pressure, and fluid monitoring; and open- and cased-hole logging.

The long-term CO2 storage effectiveness in the Mt. Simon Sandstone is being evaluated using pressure monitoring and fluid sampling through an in-zone verification well (VW1) designed to monitor the injection formation and formations immediately above the primary caprock. In May 2017, the Westbay® Instruments Multilevel Monitoring and Characterization System, a prototypical installation for a deep CCS project, was removed from VW1 after 11 rounds of sampling yielding 103 samples. The system was replaced with the Baker-Hughes Intelligent system that is currently in operation. A dedicated geophone well (GM1) facilitates repeat seismic imaging and microseismic monitoring over the life of the project.

The scale of IBDP has presented an opportunity to explore emerging technologies and develop methodologies with the long-term potential efficacy for monitoring of commercial CCS sites. The IBDP MVA program was established as a rigorous research effort to test high-density monitoring and multiple sampling techniques to gain increased knowledge of viable monitoring technologies. Based on this research, appropriate recommendations can thus be made for development of long-term commercial site monitoring programs.

The MVA program is a coordinated effort among the Illinois State Geological Survey (ISGS), Schlumberger Carbon Services, Archer Daniels Midland (ADM) Company, Lawrence Berkeley National Laboratory (LBNL), University of Illinois, TRE-Canada and the Carbon Capture Project, Physical Sciences Incorporated, Illinois Department of Transportation, and others.

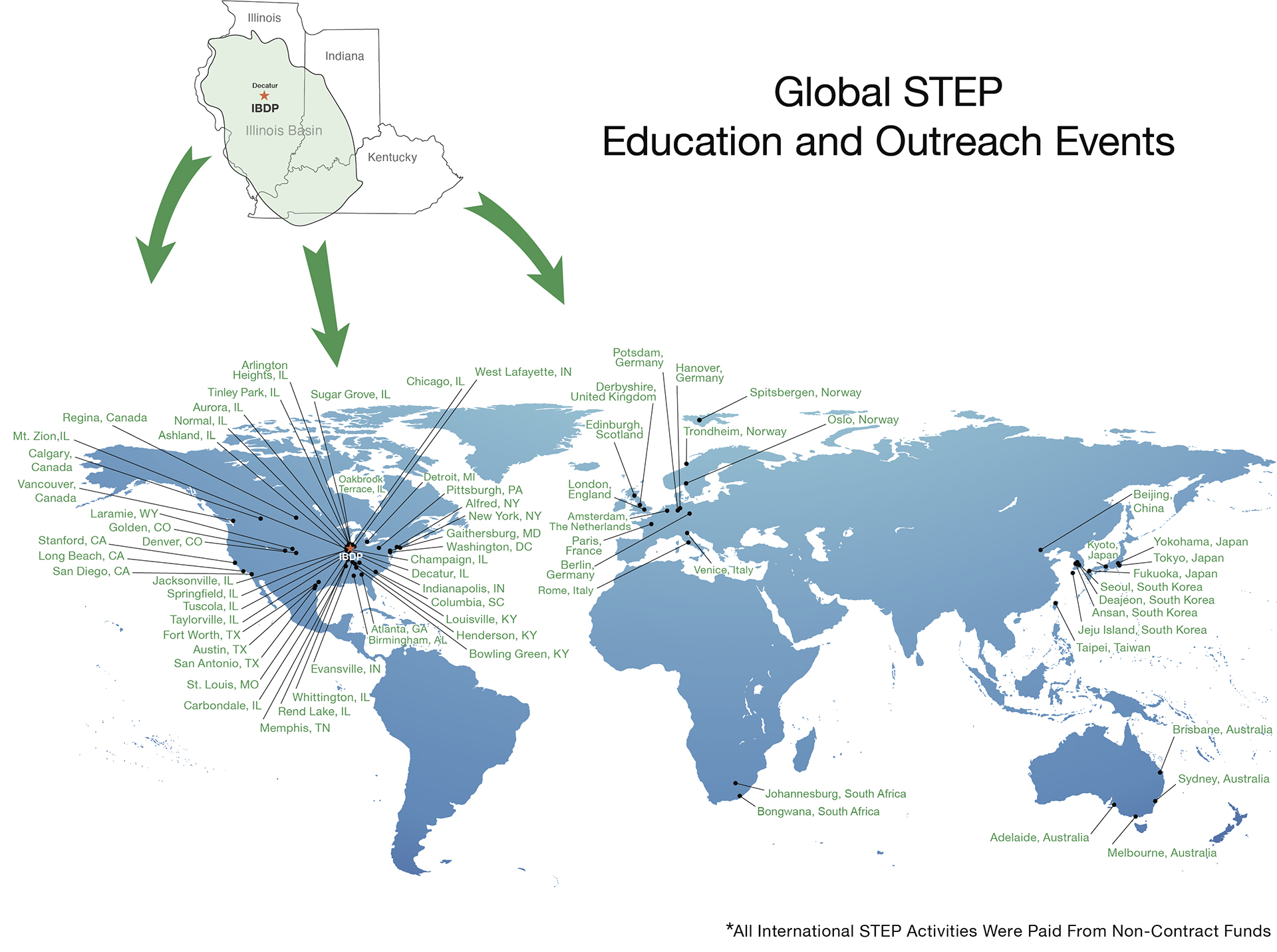

Stakeholder Engagement

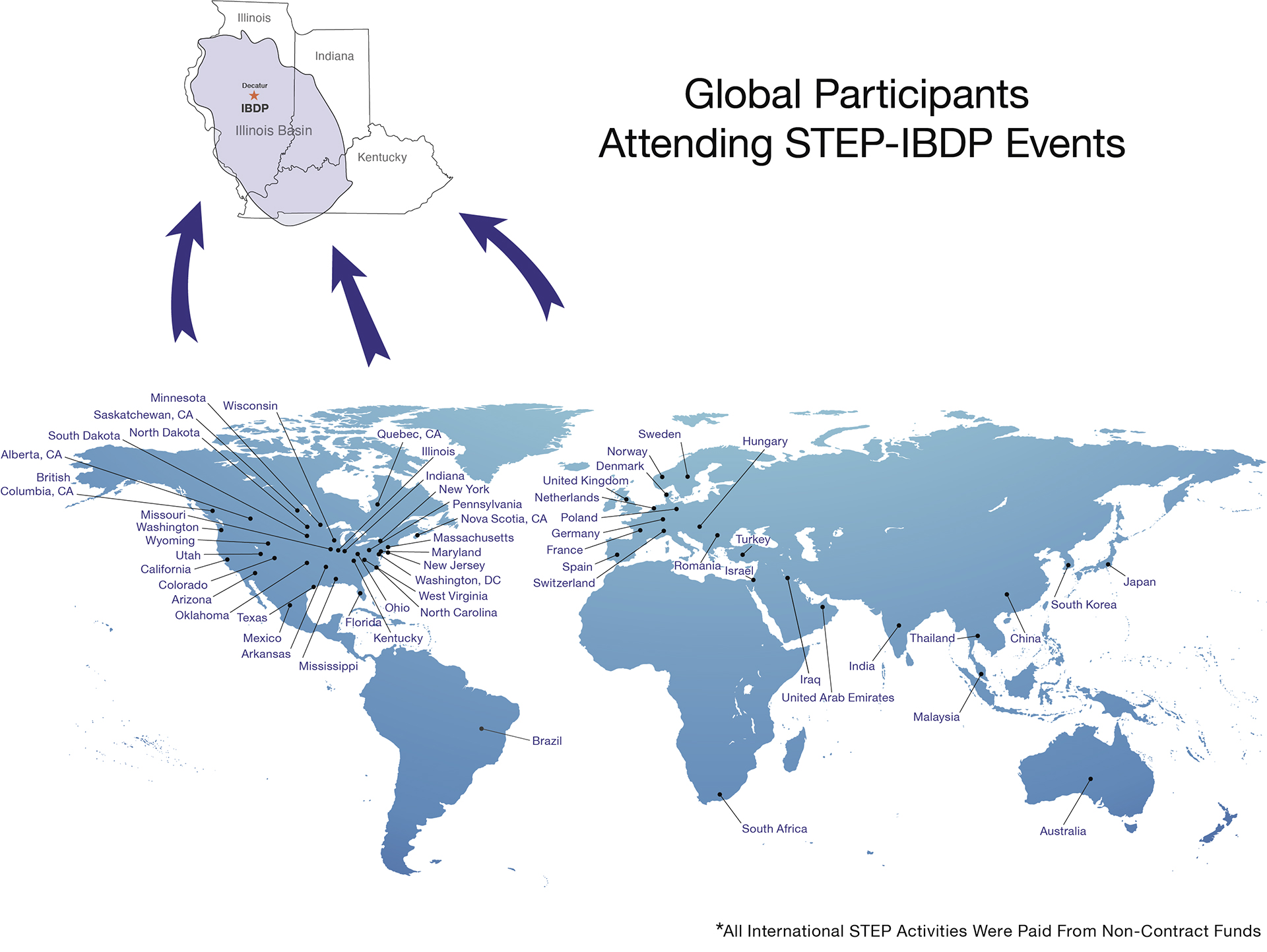

Stakeholder engagement has been a major focus of the Midwest Geological Sequestration Consortium (MGSC) throughout the Phase I, Phase II, and Phase III projects. MGSC developed strong stakeholder relationships as a function of Phase III and has demonstrated that stakeholder engagement is critical to building trust within projects. MGSC’s focus has been on developing a systematic approach to building relationships and conducting stakeholder analyses to understand the local, regional, and national context around projects and policy. Activities that have benefited the project the most involve establishing regional relationships and local relationships that build understanding and support. Engagement is a two-way communication activity necessary for commercial deployment of carbon capture and storage (CCS).

MGSC views public engagement as an opportunity to provide fact-based education and activities to engage stakeholders in issues surrounding CCS. To help build informed and supportive constituencies, MGSC outreach activities have engaged local, regional, and international stakeholders through print and online materials, open houses, presentations, model demonstrations, school visits, curriculum development, teacher professional development, stakeholder meetings, invited briefings, public hearings, short courses, workshops, and conferences.