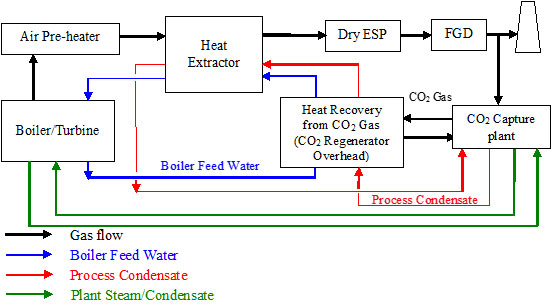

Southern Company Services, Mitsubishi Heavy Industries America (MHIA), and URS Group have teamed to develop viable heat integration methods for the capture of carbon dioxide (CO2) produced from pulverized coal combustion plants, improving upon the current state-of-the-art for solvent-based capture processes. An advanced level of heat integration between the power plant and the CO2 capture facility will be investigated by incorporating a waste heat recovery technology into an existing amine-based CO2 capture process. The project will incorporate MHIA’s High Efficiency System (HES) heat recovery and integration technology into an existing 25 megawatt electrical (MWe) pilot plant demonstration of the Kansai Mitsubishi Carbon Dioxide Recovery (KM-CDR™) CO2 capture process at Southern Company’s Plant Barry. The HES heat integration technology will use waste heat streams to provide needed process stream heating, reducing the amount of low pressure (LP) steam extracted for the solvent regeneration system. The recovered heat will also be used to heat boiler feed water, further reducing the extraction steam demands on the LP turbine and increasing the LP steam available for power generation. The HES has been successfully demonstrated at several low-sulfur, coal-fired power plants outside of the United States, though not with CO2 capture. This project will examine the HES performance with high-sulfur flue gas, and as integrated with a CO2 recovery system. A preliminary techno-economic analysis has indicated that HES with advanced heat integration can reduce the total energy impact of a CO2 capture system by 26 percent, a significant step toward meeting the Department of Energy’s goal for the cost of electricity.

Presentations_plp

- Waste Heat Integration with Solvent Process for More Efficient CO2 Removal from Coal-Fired Flue Gas [PDF] (Aug 2017)

Presented by Shintaro Honjo, Mitsubishi Heavy Industries America, Inc., 2017 NETL CO2 Capture Technology Project Review Meeting, Pittsburgh, PA

- Development and Demonstration of Waste Heat Integration with Solvent Process for More Efficient CO2Removal from Coal-Fired Flue Gas [PDF] (May 2017)

Project closeout meeting presentation

- Development and Demonstration of Waste Heat Integration [PDF] (Aug 2016)

Presented by Jerrad Thomas, Southern Company Services, Inc., 2016 NETL CO2 Capture Technology Project Review Meeting, Pittsburgh, PA

- Development and Demonstration of Waste Heat Integration With Solvent Process for More Efficient CO2Removal from Coal-Fired Flue Gas [PDF] (June 2015)

Presented by Jerrad Thomas, Southern Company Services, Inc., 2015 NETL CO2 Capture Technology Meeting, Pittsburgh, PA

- Development and Demonstration of Waste Heat Integration With Solvent Process for More Efficient CO2Removal from Coal-Fired Flue Gas [PDF] (July 2014)

Presented by Todd Wall, Southern Company Services, Inc., 2014 NETL CO2 Capture Technology Meeting, Pittsburgh, PA

- Development and Demonstration of Waste Heat Integration With Solvent Process for More Efficient CO2Removal from Coal-Fired Flue Gas [PDF] (July 2013)

Presented by Todd Wall, Southern Company Services, Inc., 2013 NETL CO2 Capture Technology Meeting, Pittsburgh, PA

- Efficient Use of Waste Heat to Reduce Parasitism of CCS [PDF] (July 2012)

Presented by Katherine Dombrowski, URS Corporation and Tiffany Wu, MHIA, 2012 NETL CO2 Capture Technology Meeting, Pittsburgh, PA

- Development and Demonstration of Waste Heat Integration with Solvent Process for More Efficient CO2Removal from Coal-Fired Flue Gas Fact Sheet [PDF] (Mar 2012)

- CO2 Capture Technology Status Sheet

Principal Investigator

Nick Irvin

jairvin@southernco.com

Project Benefits

This project is focused on improving energy performance by integrating a flue gas waste heat recovery technology into a pilot amine-based CO2 capture process at a host pulverized coal power plant. The HES provides efficient use of traditionally wasted heat in coal-fired flue gas and captured CO2 for process stream heating and boiler feed-water pre-heating, resulting in improved overall power plant performance and reduced capital and operating costs. The HES technology also has the potential for enhanced removal of sulfur trioxide and trace metals from the flue gas as a result of improved electrostatic precipitator performance. This improvement has the added benefits of reducing amine solvent loss and accumulation of metals, thereby reducing operating costs of the solvent capture process. Specifically, this project will demonstrate HES system integration with a 25 MWe KM-CDR pilot process at Southern Company’s Plant Barry.