While additives in current cement compositions and well-designed placement techniques can enhance zonal isolation in high-temperature, high-pressure wells, industry experts continue to report a high incidence of failure in deep, hot wells, presumably due to inadequate placement and mechanical failure of cements. Even when cement is placed properly, temperature and pressure gradients encountered through production can induce very high stresses in the wellbore, exceeding the resistance capabilities of conventional Portland cement systems. Short-term and long-term fluid migration of water and/or gas can also affect the sealing properties of Portland cement, and mechanical cement failure is exaggerated in wells with narrow annuli because of the stress imposed by temperature, pressure cycling, and corrosive gases such as CO2 and H2S.

Failure of the annular seal provided by wellbore cements can be due to a number of factors and be manifested in several ways. The cement can experience a gross matrix integrity failure due to imposed stress, or it can lose its bond to (usually) the inner casing, causing a microannulus flow path between the cement and pipe.

The supercement will possess superior pipe and formation-bonding capabilities to ensure a tight annular seal at depths exceeding 16,000 ft. It will also have the tensile strength, permeability, compressive strength, and expansive properties required for long-term durability, minimizing the potential for mechanical failures at temperatures exceeding 350 °F and pressures exceeding 15,000 psi. The benefits of the proposed supercement include maximized production and elimination of costly remedial work for improved well economics. In addition, the supercement will be applicable worldwide, both for wells in deep, hot environments and wells in less extreme environments that still require high stress resistance or where gas migration is a known problem.

Results

Phase I work involved a literature search on cements and evaluation of Portland and non-Portland cement systems and various formulations within these systems. Laboratory work involved more than 1,100 tests on 169 different formulations. Baseline testing established a foundation for comparison. Conventional and unconventional mechanical tests were conducted, and many systems were tested at high temperatures. From this work six candidate systems comprising some 10 formulas were recommended for further analysis in Phase II: reduced water systems, magnesium oxide, molybdenum trioxide, fibers, epoxy (resins), and graded particle systems.

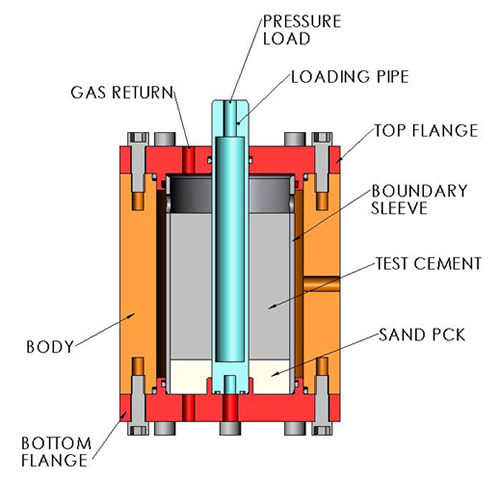

All of the mechanical testing demonstrated that no single material property is sufficient to determine annular seal effectiveness. An annular seal test fixture was developed to evaluate wellbore performance of cements. This apparatus represents a good approximation of stresses applied to cement in the wellbore.

During Phase II, researchers evaluated an epoxy-cement formulation in a gas well in the Gulf of Mexico at a platform operated by Chevron Corp. Prior attempts to use Portland cement to seal the annular area of this well had proved unsuccessful, allowing a persistent gas leak through this area. This leak was successfully sealed by the epoxy, which was subsequently applied to other wells at that platform.

Chevron then decided to apply this epoxy cement formulation, known as ULTRA SEAL®-R(LIQUID BRIDGE PLUG™), to a deeper problem, a leaking packer set at 10,599 feet inside 7-inch casing. This epoxy successfully set and sealed the leak where the temperature was measured at 205 °F. Per regulations, this seal passed a pressure test with an applied pressure of 1,000 pounds per square inch for 30 minutes. This performance qualified this epoxy cement formulation for further tests at higher temperatures and pressures.

A second supercement formulation was developed that is Portland-cement based and designed to generate substantial expansion during the curing process. This expansion in the confined wellbore environment develops significant cement matrix compressive stress during cure, resulting in a compressive pre-load. In practice, the compressive pre-load functions to elevate the effective tensile strength of the material because the compressive stress must be relieved before the material can experience tensile stress. Additionally, the pre-load functions to keep the material tightly bound to the wellbore tubulars, thereby reducing the tendency of repeated stress cycles to form a microannulus. A patent application is being filed for this material.

Benefits

Cement is a critical component in the long-term integrity and safety of any well. The objective of this project is to improve deep-well economics through the development of cements capable of tightly sealing annuli and providing the long-term integrity required in deep, hot environments. Systematic testing and analysis of various systems of Portland and non-Portland cements, as well as non-cement binding materials, will provide a few selected systems for field testing that might provide a long-term solution in high-temperature and high-pressure environments. Successful completion of this project can lower the overall maintenance costs of high-temperature, high-pressure well completions that can be productive for several decades.

Summary

The primary tasks associated with Phase III are field trials and results analysis of supercement formulations and technology transfer via seminars and technical papers.

Discussions with customers are ongoing to gain agreement to test both the resin and pre-stressed cement in wells for performance analysis. While a large number of jobs have been run with the epoxy material, researchers are looking for wells at higher temperatures. Unfortunately, expanding cements have been around for many years in the industry and do not enjoy a good reputation. Previous attempts at expanding cements focused on more modest expansion than the current pre-stressed cement material, in order to combat the inherent shrinkage of conventional cements during curing. Because of the moderate expansion, these cements do not perform substantially better than conventional cements, and claims to the contrary have soured the industry on the topic. Project researchers believe that the pre-stressed cement’s performance is significantly better than previous attempts at expanding cement but are having some difficulty convincing clients in spite of excellent lab performance testing.

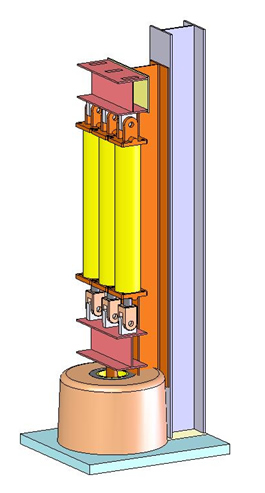

Limits to pre-stressed cement performance deal with the competence of the formation in which it is placed. Tests are ongoing to determine the level of formation competence required to provide sufficient constraint to allow the material to perform. These tests are full radial-scale shear bond tests utilizing artificial formations of various strengths.