Carbon Storage Atlas

- Why this Location

- Main Research Q&As Discovered

- Advice for Future Operators

- Field Site Story of Interest

- Geologic Details

- Links to EDX

- Project Introduction and Site Operations

- Site Characterization

- Risk Assessment

- MVA

- Commercialization

- Sites

Lat/Long

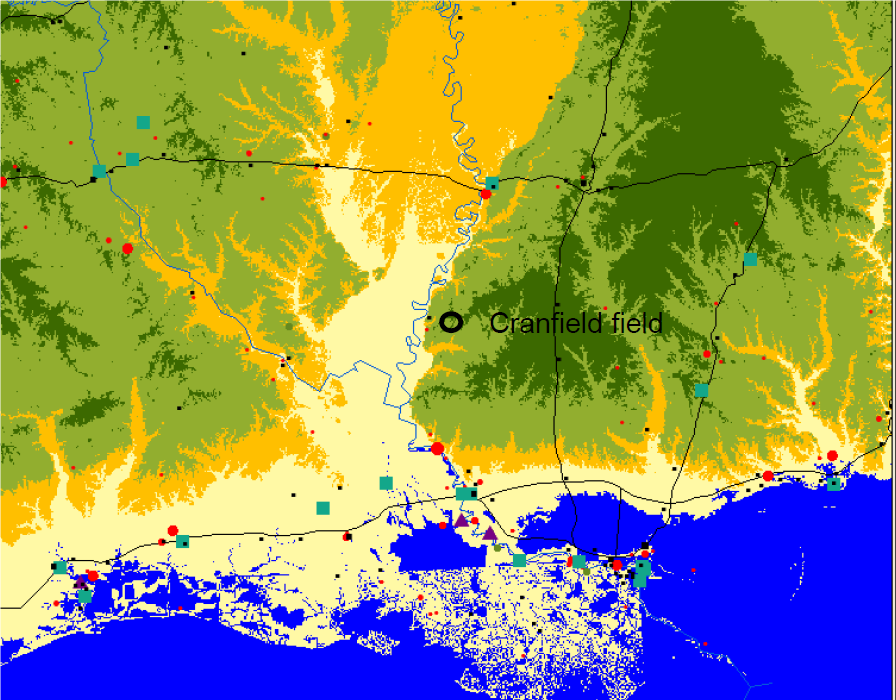

The Cranfield Project was conducted at Cranfield oilfield in southwestern Mississippi, operated by Denbury Onshore LLC. The center of the field is located approximately 21.7 kilometers (13.5 miles) from Natchez, Mississippi. The detailed area study (DAS) injection well CFU 31-1 is located at 31.563533 and -91.141487.

Why this Location

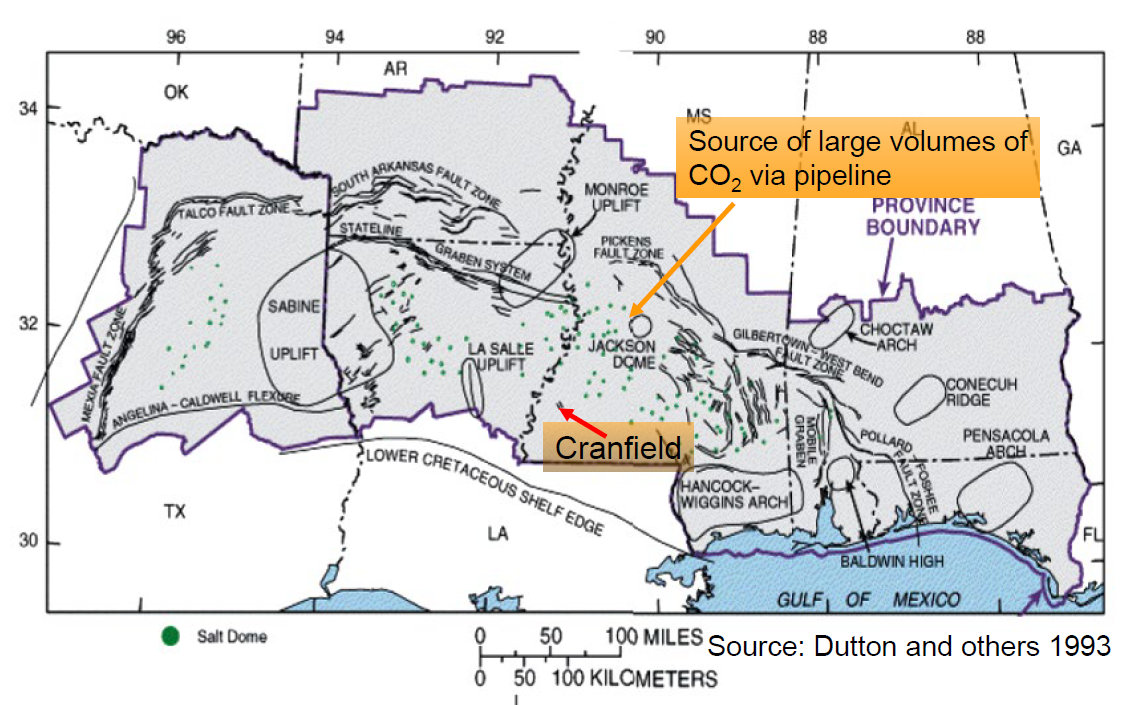

Cranfield oilfield was selected because a program goal of Phase III was to “stress the system” by injecting 1 million metric tons (MMT) of carbon dioxide (CO2). Planned capture projects would take time to develop, so an “early test” was selected so that large volumes of injected CO2 could be monitored. The enhanced oil recovery (EOR) project that hosted one of the Southeast Regional Carbon Sequestration Partnership’s (SECARB) Phase II projects had assured that more than 1 MMT of CO2 could be supplied via the near-completed retrofit of the Sonat pipeline in a short amount of time with high certainty. To document the viability of “stacking” EOR with saline storage, the downdip saline part of the field was selected, and an experimental site, the detailed area study (DAS), was developed with injection and monitoring wells completed in the lower Tuscaloosa D and E sandstones. In addition, other downdip and EOR patterns were included and monitored to assure that the injection target could be met.

The Cranfield oilfield had been idle for 40 years prior to the start of injection. The site was similar to saline settings typically found in the area because the pressure had returned to nearly hydrostatic conditions, rather than being pressure-depleted like most mature fields.

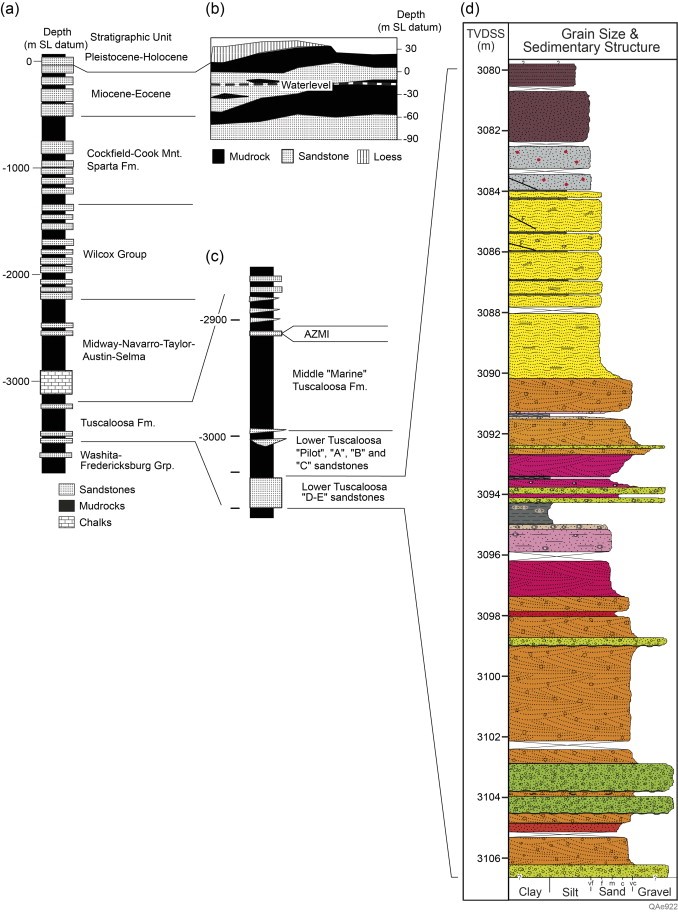

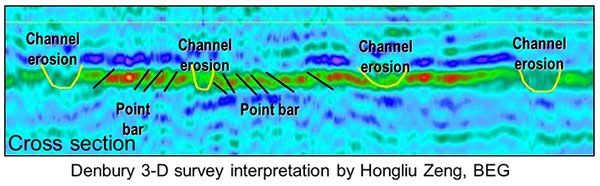

The lower Tuscaloosa in this area is composed of a sequence of channel-filling conglomerates and sandstones with depositional units a few meters thick by 1,000 meters wide. However, the channels are incised into each other, creating amalgamated sandstone flow units tens of meters thick and separated only locally by thin, fine-grained zones. The unit is well connected for single-phase flow (pressure); however, its response to two-phase flow (CO2 and brine) is complex.

Main Research Q&As Discovered

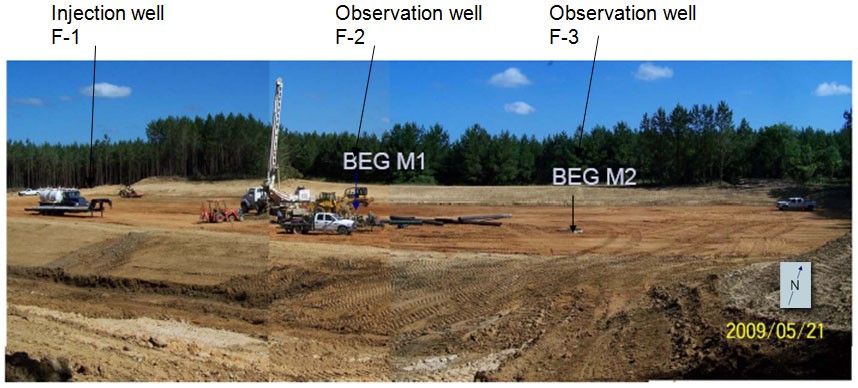

The Cranfield Project broke new ground in that it was both a large-volume injection and it was closely monitored to validate flow models. The main research question was how the evolving carbon dioxide (CO2) plume would interact with the heterogeneous injection zone facies. A linear array of an injection well and two observation wells (at 60 and 100 meters away [~197 to 328 feet]) were drilled and instrumented to assess flow processes at high spatial and temporal resolutions.

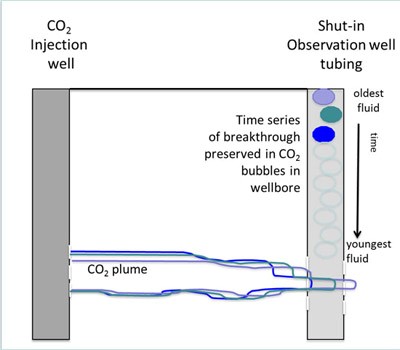

Multiple instruments were used to measure CO2 saturation changes. The purpose was both to test tools and advance tool development, as well as to measure reservoir response to injection in as much detail as possible. One of the novel deployments was electrical resistivity tomography, a first in deep carbon capture and storage (CCS) application. The array of electrodes on non-conductive casing was designed by Sandia National Laboratories (SNL) and operated and assessed by Lawrence Livermore National Laboratory (LLNL). The tools were able to detect changes in CO2 saturation in the flow field between the observation wells during the entire injection without showing a plateau in response as saturation increased from moderate to high. In addition, complex flow was observed. Initial slow breakthrough of CO2 to the nearer observation well in the upper part of the flow unit occurred as expected. However, only a few days later, large amounts of CO2 arrived in the lower part of the flow zone in the further observation well. The lower and faster travel path was not observed in the nearer observation well, documenting the importance of sinuous channels to flow paths.

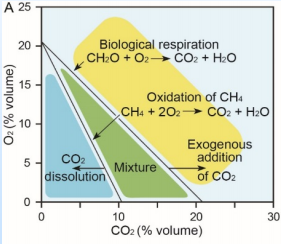

The same flow complexity is evident in the chemistry of arriving fluids. The front of the plume had high methane, a result of dissolution of CO2 and exsolution of methane as the plume interacted with brines. As injection rates increased, development of new flow paths are marked by a sharp increase in methane as well as slower-than-expected breakthrough times. Similar complex flow paths are evident in the enhanced oil recovery (EOR) part of the field, where the timing of CO2 and oil arrival is highly variable.

Advice for Future Operators

The amounts and types of monitoring conducted at the Cranfield Project were valuable for research and development (R&D) advances; however, they would not be repeated in a commercial setting. In particular, intensive cross-well monitoring that documented the evolution of the plume though time was informative in this context, but tracking a plume in this detail would not be of value in a commercial application. The complex response of both faster- and slower-than-expected arrival times resulting from complex flow paths can neither be completely or uniquely history-matched. This outcome documents an important point: only through assembling models of the complete range of possible reservoir responses to injection can confidence in secure retention be attained. In a complex geologic system, no one model can match or uniquely illustrate the range of possible outcomes of continued injection and stabilization.

In addition, although very dense data were collected, the challenging (deep, hot, and corrosive) downhole environments created limitations of both tool response and tool durability. In a commercial setting where monitoring outcomes must be reported, the operator must anticipate and budget for sufficient redundancies or work around this challenge to assure that the needed data can be collected. Simpler, more durable, and more repairable installations will be needed for commercial monitoring, and this highlights a need for improvements in monitoring equipment design.

Field Site Story of Interest

Because of the expectation that the fluvial lower Tuscaloosa reservoir would be highly heterogeneous, the team ran dozens of simulations of possible dense-phase carbon dioxide (CO2) breakthrough times at the two observation wells after an injection started on December 1, 2008. The range of predictions was large, from a few days to the end of January 2009. During breakthrough, the team needed to have several staff available at the well site on 24-hour shifts to collect geochemical and tracer data and analyze them in real time, so that additional samples could be taken at critical times. The solution to this problem was to set up Lawrence Berkeley National Laboratory’s (LBNL) quadrupole mass spectrometer in the field in a portable lab container with the U-Tube chemical sampling system and then hiring dozens of University of Texas geochemistry graduate students to come in rotation over winter-term break. One student even rotated in with her newborn baby and her mother (bringing experience in round-the-clock shift work). To celebrate the successful collection of dense data to document the fluid evolution as the first CO2 arrived at each well and the holiday, Christmas in the field lab was a festive occasion, with decorations festooning the sampling apparatus. It even snowed in Mississippi, making it one particularly memorable field season.

Geologic Details

The lower Tuscaloosa reservoir is comparable to most storage complexes: in some ways quite typical, but in others, it’s quite unique. The setting, a three-way closure above a deep-seated salt structure, is typical of many hydrocarbon fields and saline structures of the Gulf Coast. This setting is valuable because the structure enables the ultimate fate of the carbon dioxide (CO2), accumulation at the crest of the structure, to be easily assessed. However, like most similar structures, faults that accommodated extension forming a crestal graben must be determined whether they may form transmissive pathways. In this setting, hydrocarbon accumulations show that the graben-forming faults are sealing to both cross-fault and up-fault migration. The pressure response to injection showed that the faults are sealing to lateral flow in the project area.

The lithology is also both typical, being fluvial sandstones similar to many other high-quality storage reservoirs, and unique in that the sandstones initially contained high amounts of volcanoclastic grains. The volcanoclastic were dissolved during early diagenesis and served as a source for both thick rims of chlorite clays and later quartz cements. Chlorite cement prevented precipitation of later cement and preserved high porosity even to 3 kilometers (~1.86 miles) of burial.

Links to EDX

https://edx.netl.doe.gov/dataset/secarb-3d-vsp-data

Vertical Seismic Profile data collected in 2009 and 2010 as part of SECARB Phase III Early Test at Cranfield oilfield in Mississippi to determine CO2 induced change from seismic response. Data divided into 3D VSP and Offset VSP folders.

https://edx.netl.doe.gov/dataset/secarb-airborne-magnetic-and-conductivity-survey

Airborne survey data collected as part of the SECARB project from Cranfield oil site in Franklin, Mississippi. Data includes residual magnetic intensity, calculated vertical magnetic gradient, differential conductivity depth slices, and digital videos of survey flights.

https://edx.netl.doe.gov/dataset/secarb-bottom-hole-gravity-data

Borehole gravity measurements obtained during the SECARB project at the Cranfield oil site in Mississippi from CFU31-F2 and CFU31-F3 wells. Data was used to calculate density changes within the Cranfield reservoir and to test borehole gravity performance compared to a variety of other methods for monitoring the injected CO2 plume.

https://edx.netl.doe.gov/dataset/secarb-construction-and-site-info

Site information, well schematics, component diagrams, and casing tally from the SECARB project at Cranfield oil site in Mississippi.

https://edx.netl.doe.gov/dataset/secarb-core-analysis-data-and-photos

Core photos and analysis collected from Cranfield oilfield in southwest Mississippi as part of SECARB project. Cores are from CFU31F-1, CFU31F-2, and CFU31F-3 wells in the Detailed Area of Study. Data includes permeability and porosity measurements and gamma ray scans.

https://edx.netl.doe.gov/dataset/secarb-cranfield-well-logs

Borehole logs from the SECARB project at the Cranfield oil site in Franklin, Mississippi. Well logs are a part of the geologic characterization phase of SECARB; CFU 31F-1, CFU 31F-2, CFU 31F-3 well logs from Detailed Area of Study (DAS) and other well logs.

https://edx.netl.doe.gov/dataset/secarb-distributed-temperature-sensing-data

Distributed Temperature Sensing data files collected during the SECARB project from Detailed Area of Study wells (CFU F-1, F-2, F-3) at Cranfield oil site in Mississippi.

https://edx.netl.doe.gov/dataset/secarb-drilling-surveys-and-deviation

Daily drilling reports and surveys, deviation data, and gyroscopic surveys from wells CFU31F1, CFU31F2, and CFU31F3 collected from Cranfield oilfield in Mississippi as part of SECARB project.

https://edx.netl.doe.gov/dataset/secarb-electrical-resistance-tomography-data

Electrical Resistance Tomography Data collected as part of SECARB project at Cranfield oil site in Mississippi.

https://edx.netl.doe.gov/dataset/secarb-geochemical-data

Hydrotest, gas composition, injection fluid, mass spectrometer, and U-tube gas sample analysis data gathered during SECARB project at Cranfield oil site in Mississippi. Geochemical data collected as part of geologic characterization phase of SECARB.

https://edx.netl.doe.gov/dataset/secarb-images

Picture and video records of SECARB field trips, DAS site, DAS instrumentation, and casing installations.

https://edx.netl.doe.gov/dataset/secarb-petrographic-data-and-photos

Thin sections, sedimentary graphic logs, and XRD results from CFU31-F2 and CFU31-F3 wells. Data collected as part of geologic characterization phase of SECARB project at the Cranfield oilfield in southwest Mississippi. Thin sections for CFU29-12 well also included.

https://edx.netl.doe.gov/dataset/secarb-pressure-monitoring-data

Bottom-hole, above zone monitoring interval, and injection zone pressure data collected during the SECARB project in Cranfield, Mississippi to assess the relationship between pressure field and multiphase field. Submission includes 10-second interval data from Detailed Area of Study wells: CFU31-F1 (injector), CFU31-F2 (observation), CFU31-F3 (observation) and Ella G Lees no. 7 (observation) well located west of the DAS.

https://edx.netl.doe.gov/dataset/secarb-soil-gas-monitoring-data

Soil-Gas monitoring data collected at the P-site and DAS study locations during SECARB project at Cranfield oil site in Mississippi. Data was used to study influence of gravel pad, pit, plants, and plugged and abandoned (P&A) oil well on near-surface soil-gas compositions.

Project Introduction and Site Operations

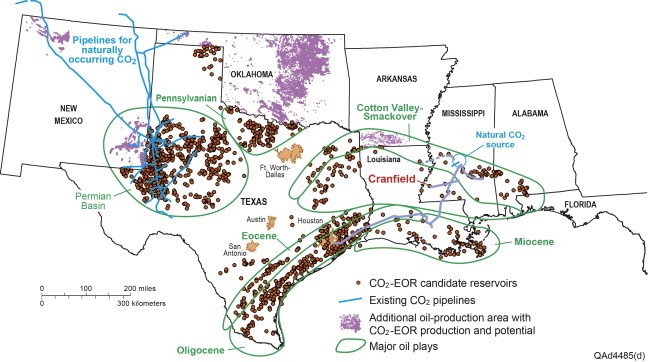

The Southeast Regional Carbon Sequestration Partnership’s (SECARB) Cranfield Project was designed to safely demonstrate large-scale, long-term carbon dioxide (CO2) injection and storage in a CO2-enhanced oil recovery (EOR) operation and associated saline reservoir. Storage during EOR operations has the potential to offset commercial costs, holding a significant promise for future large-scale deployment in the southeastern United States. Denbury Onshore LLC began CO2-EOR operations in July 2008 at the Cranfield oilfield located east of Natchez, Mississippi. The location offered an ideal setting to investigate storage monitoring at a commercial CO2-EOR operation. The field team, led by the Gulf Coast Carbon Center of the Bureau of Economic Geology at the University of Texas at Austin (GCCC), deployed the largest suite of monitoring, verification, and accounting (MVA) technologies to collect data to assess long-term CO2 utilization and storage.

The CO2 injection interval is within the 3,000-meter-deep (~9,843-feet-deep) fluvial lower Tuscaloosa Formation, a large and regionally extensive saline reservoir, at a broad four-way structural closure that defines the Cranfield oilfield. Tests were conducted in the oil-producing area, as well as in the non-oil-producing brine aquifer. The CO2 used during EOR operation was transported via pipeline from the Jackson Dome, a natural source of CO2.

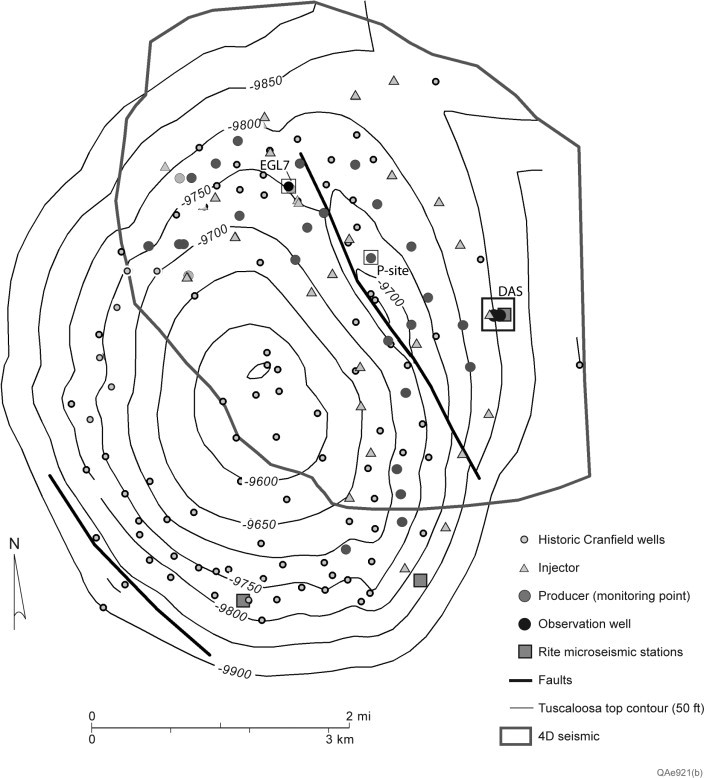

The study focused on four integrated research areas: (1) the High-Volume Injection Test area (HiVIT); (2) the detailed area of study (DAS); (3) the Geomechanical area; and (4) the near-surface observatory, also called the “P-site.” The injection of CO2 occurred at the HiVIT and the DAS.

The DAS is located downdip of the oil-water interface of the Cranfield oilfield. The well layout includes one injection well and two downdip observation wells.

The team was the first of the Regional Carbon Sequestration Partnerships (RCSPs) to monitor more than 1 million metric tons (MMT) of CO2. At the end of the project, the team monitored more than 5 MMT of CO2 stored.

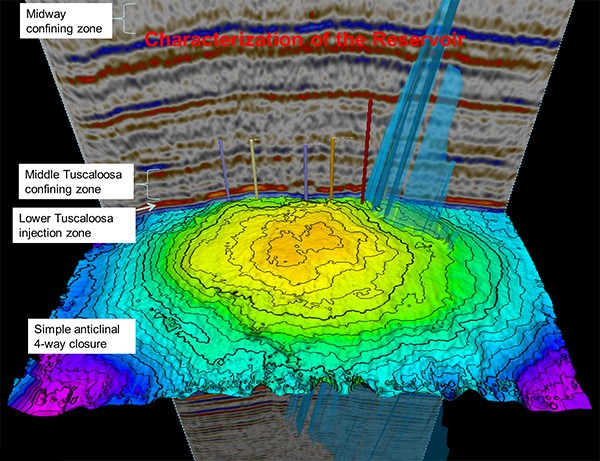

Site Characterization

The Cranfield Unit is in a large, domical structure at depths greater than 3,000 meters (10,000 feet), with a gas-tight mudstone seal atop the oil-bearing unit. The 20- to 28-meter-thick (~66- to 92-feet-thick) target injection zone is in the lower Tuscaloosa, which lies above a regional conformity in valley-fill-fluvial sandstones and conglomerates separated by alluvial and overbank within-unit seals. The reservoir is composed of stacked and incised channel fills and is heterogeneous, with flow unit average porosities of 25% and permeability ranging from 50 millidarcies (mD) to 1 Darcy.

The Southeast Regional Carbon Sequestration Partnership (SECARB) team characterized the surface and subsurface. Numerical models were developed and used to quantify the response of the reservoir to injection and migration of fluids. Monitoring was used to validate the conceptual and quantitative predictions made in the models and to support project goals.

The characterization study was based on 3D seismic data and analysis of three cores from the reservoir interval and one core from the middle Tuscaloosa confining unit. The drill cores were described and logged. Samples were taken from the cores for microscopy, X-ray diffraction, porosity, and permeability analysis. Carbon dioxide (CO2)-brine steady-state flow-through experiments were conducted to investigate relative permeability and residual saturation. A sedimentary and mineralogy and diagenesis characterization was conducted for the reservoir unit and an overburden characterization was conducted for the overlying zone. Further, the field characterization also provided insights into the trapping processes that help trap injected CO2. The four-way closure of the injection zone ensures effective structural trapping of buoyant CO2.

The historic use of the field yielded an abundance of operational and production data useful in assessing storage capacity. In addition to the extensive reservoir data for formation characterization available at the start of the study, the team augmented that data by collecting log suites, hydrologic investigations, two reservoir cores, and one mudrock core. The team also used stratal slicing to assess the 3D seismic volume. The team applied a risk assessment methodology to consider potential CO2 pathways to the surface and developed novel distributed temperature and above-zone pressure monitoring systems to assess the design effectiveness of isolation of the injection zone.

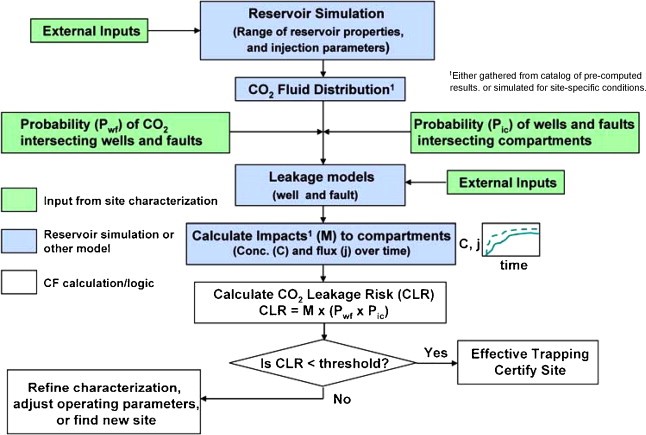

Risk Assessment

The Cranfield risk management efforts focused on assessing operational risks related to the site and demonstrating a formal risk assessment methodology supported by the U.S. Department of Energy (DOE) through the Carbon Capture Project (CCPII), known as the Certification Framework (CF). The CCPII team performed a risk assessment for the site, identifying vintage wells as the most significant risk. More than 60 vintage wells (1945 to 1950) intersect the injection interval. This risk is managed by the oilfield operator in accordance with Mississippi regulations.

The Cranfield Project employs an integrated simulation and modeling program that begins with characterization and extends through several types of predictive modeling, including monitoring planning, monitoring modification in response to improved data, and monitoring long-term injection. This iterative process is cross-disciplinary. Modeling is important to assess the integrity of each data collection effort, helping to reduce uncertainties.

A multitude of organizations and partners involved in the modeling program at Cranfield contributed to the application of an array of tool and approaches. A suite of subsurface modeling tools were deployed, including: analytical assessment of pressure from gas storage literature; one-dimensional seal flux assessment; an innovative use of simplification of fluid properties to represent water, oil, and gas in the far field; GEM-CO2 for the multiphase fields; and COMSOL for the geomechanical assessment. Multiple probabilistic realization of the quantitative static geocellular model were constructed in Petrel and input into GEM-CO2 for assessment of multiphase flow in the east side of the field around the detailed area of study (DAS). For geochemical assessments, PHREEQC and Geochemists Workbench are used for single-phase regions, and CORE2D and TOUGHREACT were used to model multiphase reactive volume transport and multiphase flow. Other teams modeled various perspectives of flow. Data was provided to the approach comparison study, SIM-SEQ. The Cranfield Project was the first application and validation of “above-zone monitoring interval” pressure monitoring at a CO2 storage site.

MVA

The Southeast Regional Carbon Sequestration Partnership (SECARB) adheres to a vigorous monitoring, verification, and accounting (MVA) program. For the Cranfield Project, sweep efficiency is monitored by saturation measurements along well bores, crosswell measurements, and vertical seismic profiling (VSP) and/or surface seismic methods. The team designed a field-wide monitoring program to document the storage of large volumes of carbon dioxide (CO2) and several focused field area projects.

The technologies used in field-wide monitoring include time-lapse 3D seismic survey, area-wide groundwater and soil gas surveillance, and a six-well microseismic arrays with commercial production data providing calibration points. The sensitivity of controlled experiment, aquifer characterization, and reactive transport modeling was assessed whether detection of CO2 release would be detected. An airborne magnetic and conductivity survey was conducted as an experiment to better characterize the shallow subsurface.

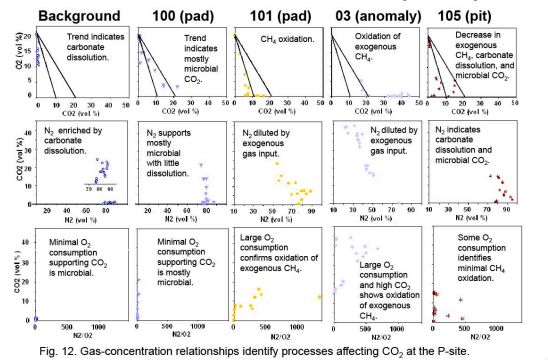

The soil gas study (P-site) assessed a local high methane concentration with ratios of nitrogen (N2), oxygen (O2), CO2, and methane indicative of gas migration. Gas ratios and stable isotopic relationships show that methane had been microbially oxidized to CO2. C14 analysis of the soil gas showed that it is not sourced from the target formation.

At the detailed area of study (DAS), approaches using different physics were employed to assess how CO2 migrated through the stratigraphically and diagenetically complex sand-rich fluvial injection zone. A first-of-its-kind, deep electrical resistance tomography (ERT) deployment was conducted between wells and inverted to provide high-frequency (daily) images of the change in the resistivity as CO2 was substituted for brine. The inversions show that flow meandered through channels, with higher saturation reaching the well furthest from injection, an effect also documented with tracers. For the first time, geochemical sampling detected dissolving CO2 led to methane coming out of solution. The closely spaced well array at the DAS enable unique observations of fluid flow.

The combination of diverse data collected at Cranfield and comparing whether they successfully captured CO2 movement was due largely in part to the complex suite of monitoring technologies deployed over various zones within and above the injection zone. Results demonstrate that the Cranfield oilfield and Tuscaloosa sandstones provide effective containment of CO2 when risks are managed properly.

Commercialization

Work completed during the Southeast Regional Carbon Sequestration Partnership (SECARB) project laid the groundwork for future fully integrated carbon dioxide (CO2) capture and storage (CCS) facilities in the southeast. In order to further the commercialization of carbon capture, utilization, and storage (CCUS) in the region, project partners share data, results, and lessons learned with the regional, national, and international community. The novel technologies and applications developed at the Citronelle and Cranfield Projects are used commercially and have been adopted at other CCUS sites as a standard of monitoring activities.

During project development, the SECARB partners focused on designing and operating a fully integrated project that would demonstrate the full CCUS value chain from a coal-powered electricity generating facility (the CO2 source) to a regionally significant geologic storage formation. The Citronelle Project was able to achieve and demonstrate the following objectives:

- Design and operate the largest commercial prototype pulverized coal integrated CCUS project in the United States.

- Investigate the CO2 flow, trapping, and storage mechanisms, both locally and regionally.

- Demonstrate the reservoir’s ability to maximize CO2 storage and minimize the areal extent of the CO2 plume.

- Investigate the adaptation of commercially available oilfield tools and techniques for monitoring, verification, and accounting (MVA) application.

- Investigate experimental CO2 monitoring tools that hold promise for future commercialization

- Document the complete permitting process.

- Assess and document a register of communication and project-related risks and a mitigation plan associated with the integrated project involving multiple entities and responsible parties.

- Analyze and assess the integration of project components.

The lessons learned from the Citronelle Project have been applied at several CCUS projects, including Mississippi Power’s Carbon Storage Assurance Facility Enterprise (CarbonSAFE; storage complex) project at Plant Ratcliffe and the Petra Nova Project in east Texas.

Proving the value and success in demonstrating a fully integrated CCUS project, SECARB’s 25-megawatt-electirc (MWe) demonstration at Alabama Power Company’s Plant Barry in Bucks, Alabama, served as the model for the Petra Nova 240-MWe capture system at NRG’s W.A. Parish Generating Station near Houston, Texas, completed in April 2017.

Within the SECARB region, there are significant geologic storage and CO2-enhanced hydrocarbon recovery opportunities that could be developed into commercial-scale CCUS projects. Opportunities for commercial-scale CCUS were initially focused on enhanced oil recovery (EOR), but the 2018 Balanced Budget Act made significant changes to previously available tax credits for CCS. The amendments to Section 45Q of the Internal Revenue Code (U.S. Code Title 26) tax credits increased the amount and duration of the tax credit available for geologic storage and storage resulting from utilization. The increased value of 45Q tax credits provides important incentives for the development of commercial-scale storage sites within the region. The ability to generate tax credits though utilization or geologic storage can be used to offset some, or all, of the costs of capture, making large-scale commercial application more viable in the region.

Within the SECARB region, several geographic areas have been identified that have good prospects for future commercial-scale CCUS projects:

- The Louisiana Chemical Corridor contains large concentrations of industrial emitters of CO2 and is located near oilfields that have been identified as good candidates for CO2-EOR.

- The Houston Ship channel contains large concentrations of industrial emitters of CO2 and is located near oilfields that have been identified as good candidates for CO2-EOR.

- Both the Louisiana Chemical Corridor and the Houston Ship channel have access to good onshore geologic storage options, as well as future offshore storage and utilization opportunities.

- Within Appalachia, enhanced shale gas recovery or enhanced coalbed methane may prove commercially viable through CO2 well stimulation.

- The Tuscaloosa Formation, which extends across large portions of the region, has similar properties to high-capacity storage formations in other regions and may be a good candidate for safe and secure geologic storage.

Commercialization efforts include education and outreach activities to foster additional support for commercial CCUS deployment within the region.

![Chlorite cement on sandstone grains preserves porosity even at 3-kilometer (~1.86-mile) burial depth (scanning electron microscope [SEM] photograph by M. Kordi).](https://netl.doe.gov/sites/default/files/Carbon%20Storage%20Atlas/SECARB/PhaseIII/Cranfield%20Fig%204.jpg)