Site: Lignite Field Test

Type: Saline

Lat/Long:

48.55 -102.25

Why This Location

Phase I of the Plains CO2 Reduction (PCOR) Partnership identified carbon dioxide (CO2) injection into deep unmineable coal seams, enabling enhanced methane production, as an opportunity for market-driven, commercial geological storage.

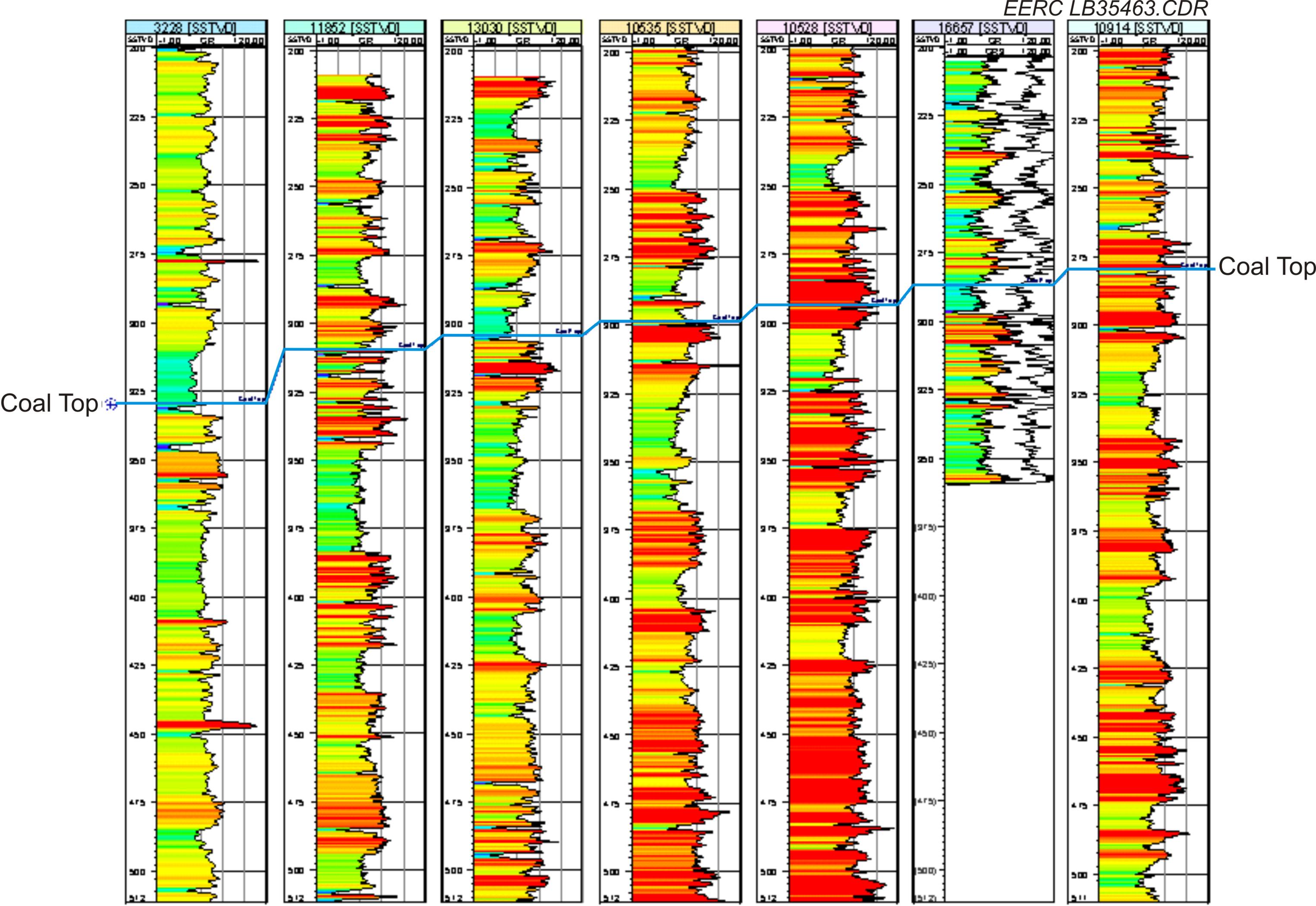

Both technical and non-technical factors provided site-selection criteria for the field test site. Subsurface data from the North Dakota Industrial Commission (NDIC) Oil and Gas Division provided characterization data from historic wells, allowing screening out of coals with economic and technical potential for future mining operations. Several coal seams of the Tertiary/Paleocene-aged Fort Union Group provided potential injection targets for the test; various technical criteria led to the selection of a target lignite coal seam at approximately 335 meter [1,100 feet] depth below surface. The location of the site in Burke County, northwestern North Dakota, was driven by landownership and mineral rights considerations, with clear preference for state-controlled land to host the test site.

Research Q&As Discovered

The field test was undertaken with the intention of providing evidence to help resolve key questions around enhanced coalbed methane (ECBM) production and associated storage of carbon dioxide (CO2). First and foremost, could CO2 be safely injected and stored in a coal seam? The field test successfully injected 80 metric tons of CO2 across nine phases of operation, eight of which injected gas-phase CO2 and one liquid-phase CO2. Challenges were, however, encountered in execution of the field test; most notably, the coal seam was significantly under-pressured in comparison to anticipated conditions, affecting well-drilling, injection, and completion activities. Combined with the intrinsic low hydraulic conductivity of the coal seam, this under-pressure precluded pumping tests typically used to determine hydraulic characteristics. Without the use of standard industry well stimulation techniques such acidization, which would have complicated interpretation of petrophysical characteristics of the coal, injection rates achieved during the test were relatively low. Injectivity remains a significant challenge for future commercialization of coalbed storage and ECBM.

The field test also sought to assess technology options for monitoring CO2 storage in coal seams. Owing to the relatively low injectivity achieved by the field test, several monitoring technology options, including microseismic monitoring and tracer studies, were not successfully applied. However, time-lapse crosswell seismic tomography provided imaging of the injected CO2 distribution where distances between wells were relatively small. Comparison of downhole logging data before and after injection also proved effective in delineating the distribution of injected CO2.

Conclusions on the economic feasibility of ECBM could not be drawn from the field test, since methane concentrations in the lignite coal seam encountered by the test were low. However, many of the technical findings of the field test can help inform future projects, and the issue of under-pressurization may have wider regional significance.

Lessons Learned that Impacted Phase III Design?

The Plains CO2 Reduction (PCOR) Partnership did not pursue a Phase III large-scale field test for coal seam injection under the U.S. Department of Energy’s (DOE) Regional Carbon Sequestration Partnership (RCSP) Program. However, experience gained from the Phase II Lignite Field Test provided valuable lessons for the conduct of any future larger-scale demonstration injection projects.

Detailed well information on the relatively shallow depths that typify regional opportunities for unmineable coal seam injection may be sparse. Unexpected subsurface conditions for drilling and injection are possible and may require contingency planning; downhole logging techniques can provide invaluable data prior to injection. Injectivity is likely to be a challenge for coal seam injection, and acidization (a standard technique for coalbed methane operations) can complicate demonstration test data interpretation.

The Phase II field test also provided much of the information used to formulate a Regional Technology Implementation Plan (RTIP), freely available on the PCOR Partnership website.

Story of Interest

The Phase II Lignite Field Test represented the first opportunity for University of North Dakota Energy & Environmental Research Center (EERC) staff working on the Plains CO2 Reduction (PCOR) Partnership Program to establish prospects for carbon dioxide (CO2) geological storage through drilling and sampling of the subsurface. Now Vice President for Research after a long and distinguished career at EERC, Ed Steadman was at the time principal investigator for the PCOR Partnership. Ed recalled the sense of excitement in August 2007 as field operations commenced and data accumulated.

“Driving over the brow of a nearby hill and seeing the drilling rig set up for the first time was an emotional moment for me, feeling very much like the culmination of years of PCOR Partnership desk-based research and months of detailed planning for site operations. We were, of course, indebted to many PCOR partners, not least the amazing support of the North Dakota Industrial Commission. The downhole conditions encountered during drilling proved different from those anticipated, most notably because of relatively low pressures in the targeted injection zone. Nevertheless, we installed all required infrastructure and proved that CO2 could be injected into deep unmineable coal seams.”

Despite the established practices of large-scale CO2 injection for both dedicated storage in deep saline formations and enhanced recovery with associated storage, injection into coal seams remains elusive at industrial scale. “The technical potential remains for enhanced coalbed methane and resulting associated storage to play a significant role in future [carbon capture, utilization, and storage (CCUS)] deployment,” commented Ed.

Geologist Rock-Fest

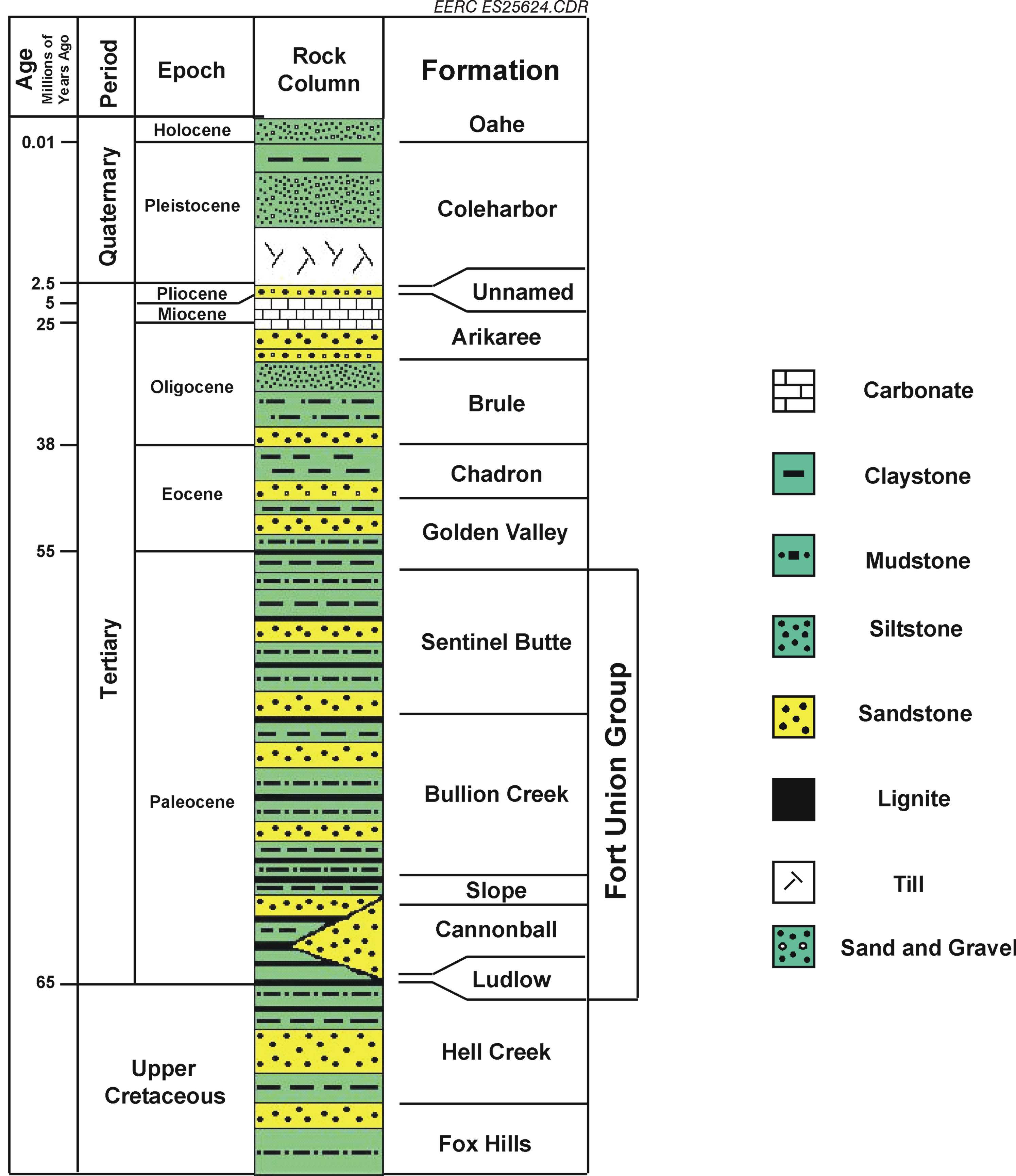

Most of the coal (lignite) in North Dakota is found within the sediments of the Fort Union Group (Tertiary/Paleocene). Fort Union Group sediments were deposited as a clastic wedge thinning from eastern Montana into North Dakota (Murphy and Goven, 1998). In general, the entire Fort Union Group can be described as consisting of alternating interbeds of sandstone, siltstone, clays, and lignite, with some limestone. The lignite beds (seams), as with most other Fort Union sediments, were deposited in a complex fluviolacustrine environmental system. Lignite seams vary in thickness and distribution and range from a foot to a few feet in thickness. The thickest lignite seams in North Dakota are in the 10-meter (30-foot) range (Murphy and Goven, 1998).

Through field test activities, the lignite formation, at a depth of approximately 335 meters (~1,100 feet), was found to be under-pressured (~345 pounds per square inch absolute [psia] versus an expected pressure of ~470 psia). The under-pressure resulted in overbalanced drilling and the plugging of potential permeability. The lower reservoir pressure was a likely cause of the observed low methane content in the formation. .

Reference

Murphy, E.C., and Goven, G.E., 1998, The coalbed methane potential of North Dakota lignites:

North Dakota Geological Survey Open File Report 98-1, 38 p.

Links to Phase II EDX Data/Documents

CO2 Flood Design for Simultaneous Evaluation of Carbon Sequestration and ECBM Recovery

https://edx.netl.doe.gov/dataset/CO2-flood-design-for-simultaneous-evaluation-of-carbon-sequestration-and-ecbm-recovery

This document describes the basic elements of the planned CO2 injection activities that were conducted as part of the PCOR Partnership Phase II Lignite Demonstration Project.

PCOR Partnership Phase II – CO2 Sequestration Validation Test in a Deep, [Unmineable] Lignite Seam in Western North Dakota Regional Technology Implementation Plan

https://edx.netl.doe.gov/dataset/regional-technology-implementation-plan-lignite-validation-test

Deliverable report of the regional technology implementation plan for the Lignite Validation Test.

PCOR Partnership Phase II – Burke County, North Dakota, Lignite Demonstration Site Finalized Drilling Prognosis for the Five-Spot Research Wells for the Lignite Field Validation Test

https://edx.netl.doe.gov/dataset/finalized-drilling-prognosis-for-the-five-spot-research-wells-for-the-lignite-field-validation-test

Finalized drilling prognosis for the Lignite Field Validation Test.

Lignite Field Validation Test in Burke, County, North Dakota: Sampling Protocol

https://edx.netl.doe.gov/dataset/lignite-field-validation-test-in-burke-county-north-dakota-sampling-protocols

Lignite Field Validation Test in Burke County, North Dakota, sampling protocols.

PCOR Partnership Phase II – Burke County, North Dakota, Lignite Demonstration Site Experimental Design Package

https://edx.netl.doe.gov/dataset/task-4-burke-county-north-dakota-lignite-demonstration-site-experimental-design-package

Lignite Demonstration Site experimental design package.

PCOR Partnership Phase II – Task 4 – Lignite Field Validation Test

https://edx.netl.doe.gov/dataset/lignite-field-validation-test-regulatory-permitting-action-plan

This Regulatory Permitting Action Plan (RPAP) describes the regulatory and permitting steps taken by the Energy and Environmental Research Center (EERC) and its partners to conduct the Lignite Field Validation Test. The RPAP discusses the general permitting requirements for EERC. Additionally, relevant federal and provincial regulatory summaries are provided.

PCOR Partnership Phase II –Lignite Field Validation Test – Outreach Action Plan

https://edx.netl.doe.gov/dataset/outreach-action-plan-lignite

The outreach action plan for the Lignite Field Validation Test.