Basinal Phase (Phase 1): Carbon Ore, Rare Earth and Critical Minerals (CORE-CM) Initiative

The basinal phase will focus on the following six objectives:

1. Basinal Assessment of CORE-CM Resources

CORE-CM projects will conduct an initial basinal resource assessment. Each basinal assessment will address resources and volumes in the following five categories:

- Coal sediments (sedimentary layers associated with coal beds);

- Coal ash (ponded materials; combustion fly ash/bottom ash by-products);

- Refuse (coal; other ores);

- Acid mine drainage (coal; other ores);

- Other. This resource category is required to be basin specific and may be identified for future rare earth element and critical mineral resource assessments. “Other” may include, but not be limited to, gasifier char materials, coal or other ore tailings or prep plant wastes, and produced water (petroleum industry byproducts and other produced waters).

![]()

The initial Basinal Resource Assessments will address previous and, if applicable, ongoing studies that identify and assess resources and volumes of the REE and CM concentration and mode of occurrence within each of the above categories using best practice methodologies such as those defined by USGS or State Geological Surveys.

The initial Basinal Resource Assessment will include but not be limited to:

- A review and assessment of prior state-of-the-art (SOTA) REE and CM data as well as, if applicable, ongoing studies, that will address how these data were/are being obtained.

- Identification of the carbon ore-based resources and/or other resources, their location within the basin, and estimates of the quantity of each resource contained within the basin.

- Identification of coal waste streams (coal ash, refuse, acid mine drainage, etc.), their location within the basin, and estimates of the quantity of each material contained within each basin.

- The results of a gap analysis that addresses the potential need for additional field sampling activities to adequately reflect the basin’s resources.

- A description of the requirements, processes and methodologies for acquiring additional field materials and performing respective characterization analyses of resource materials in each U.S. basin.

The initial Basinal Resource Assessment is a high-level prospective assessment and will serve as the foundation for future data and information refinements of the basinal REE- and CM-containing resources.

This effort will serve as a preliminary evaluation identifying the most promising resources within each U.S. basin. With respect to coal sediments, REE and CM geologic models will initially be developed that include structural and stratigraphic frameworks, paleo depositional environments, and post-depositional processes.

The geologic model initiated in Phase 1 and completed during Phase 2 will be extrapolated across the basin and may include newly generated REE and CM assay information as well as coal chemistry and geochemistry information needed to develop a reasonable, more informed research plan. Assays that can be directly associated with specific stratigraphic clay intervals should additionally be addressed and included in the geologic model. If available, other geophysical data such as well logs, seismic and geochemical information, etc., are being identified.

In Phase 2 or Phase 3, the predictive capability of the resource assessment geological models will be validated.

Based on the initial Basinal Resource Assessment gap analyses, a Characterization and Data Acquisition Plan will be developed that addresses and justifies the need for acquiring, characterizing, and analyzing additional field samples in order to provide an accurate account and future prediction of the REE, CM and carbon resource within the basin for future commercial use.

The Characterization and Data Acquisition Plan will include:

- A description of what additional data are needed to fill the information gaps in order to develop geologic models that identify and predict deposits (resources and volumes) and waste stream materials with the highest REE and CM concentrations as well as their potential ease of extraction (mode of occurrence). The proposed data acquisition plan should consider piggybacking on existing planned drilling activities within the basin.

- A detailed description of the proposed geologic sampling (method and location) and analysis plan and how this effort will serve to fill the data information gaps related to REE and CM concentrations for each of the five resource categories previously described. The sampling plan should consider piggybacking on existing planned drilling activities within the basin.

- A description of the methods and accuracy of the analytical characterization techniques that will be utilized to determine REE and CM concentrations. If needed, field sampling and characterization on a limited basis may include, but not be limited, to acquiring additional surface outcrop or subsurface resource materials or may include acquiring archived well bore or core sample materials in order to develop a more informed Phase 1 Characterization and Data Acquisition Plan.

Determining the elemental REE and CM concentrations in these materials, as well as obtaining critical stratigraphic well log information or geophysical data, etc., may be essential with respect to the development of basinal geological models expected during subsequent Phase 2 and Phase 3 activities.

All field sample characterization analyses generated during Phase 1 for each U.S. basinal area will be assimilated by award recipients into two database templates that are provided by NETL. Once submitted to NETL as a Phase 1 deliverable, the first database template which identifies a general description of the resource material and its sampling location will be uploaded into NETL’s REE-CM EDX website. That information will be made publicly available, similar to data obtained for all projects performed in the NETL REE-CM portfolio.

Once populated and submitted to NETL, a second database template which contains a detailed description of the resource material and specifics relative to sampling location will be utilized by NETL EDX sampling and analysis template.

NETL’s RIC personnel will develop parallel and potentially collaborative predictive geologic models. Recipients will provide NETL with a single split REE and CM sample for each type of material or core sample assessed in Phase 1 (and if appropriate in continuing phases) that reflects the highest achieved REE or CM concentration identified during conduct of the project effort, and which reflects materials used by the award recipient for its economic assessment.

2. Basinal Assessment for Reuse of Waste Streams

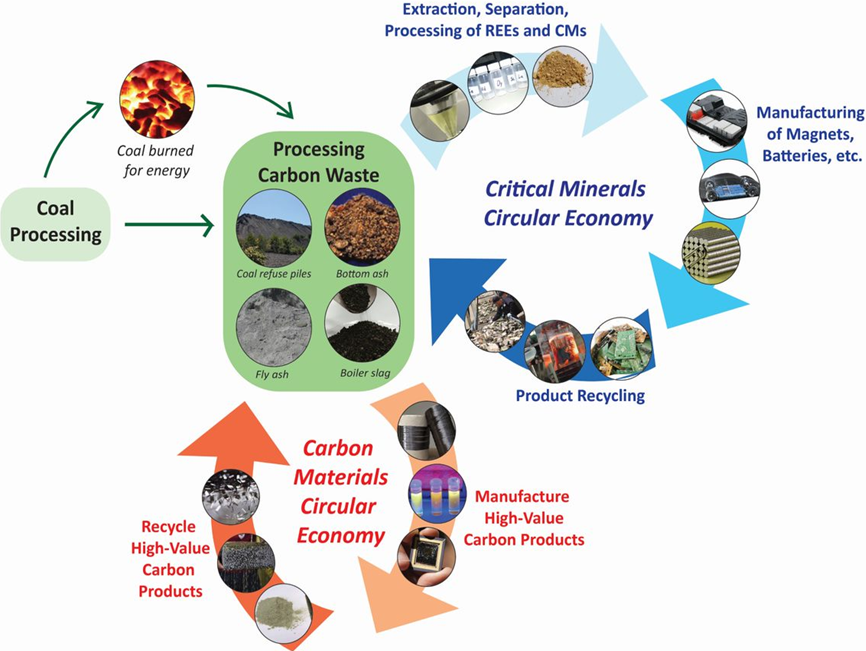

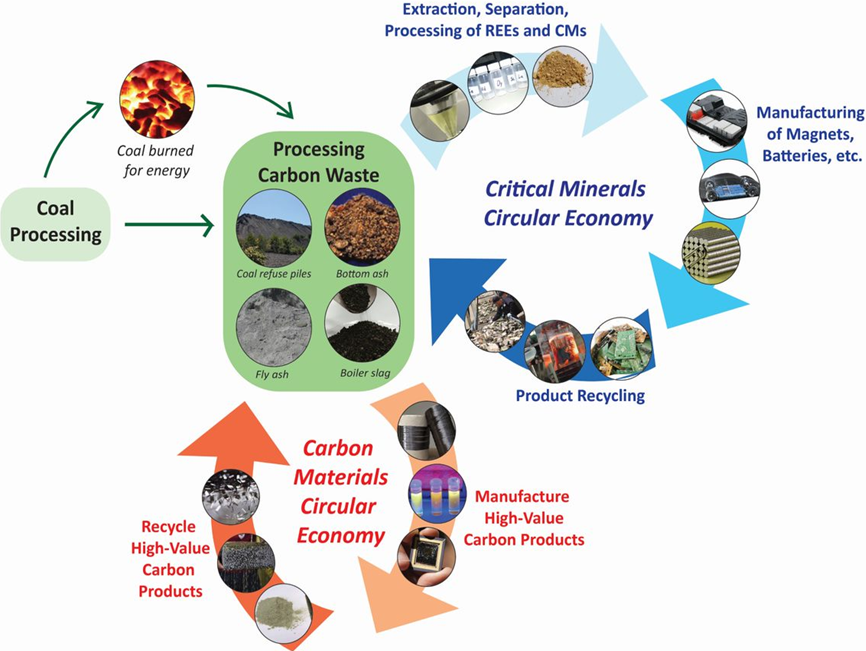

CORE-CM projects will assess regional waste streams (including wastes and byproducts associated with carbon-ore mining) that could be reused as fuels, feedstocks, or consumables in processes that produce REE, CM and/or high-value, nonfuel, carbon-based products and other by-products. The assessment will include acquiring existing data, identification of information gaps, and the development and implementation of R&D plans to fill those gaps and enable future projects within the region.

A preliminary Waste Stream Reuse Plan will be developed that addresses:

- Potential engagement with energy, environmental and reclamation state and federal entities relative to waste stream materials.

- Identification of potential partnerships with other entities for conducting future small-scale R&D projects for innovative waste stream material technology and/or test facility development.

- Innovative waste stream material technology development may include potential co-product production as well as process development. For example:

- Extraction and recovery of REE and CM from fly ash, with utilization of residual aluminum in the cement or aggregate industry sectors.

- Utilization of sulfuric acid generated from coal-based acid mine drainage as the chemical leaching media to extract REE and CM from coal or alternate resource feedstock material.

- The challenges and potential solutions needed to realize the above and/or alternate waste stream reuse opportunities.

3. Basinal Strategies for Infrastructure, Industries and Business

CORE-CM projects will assess regional infrastructure, industries and businesses and formulate strategies to integrate and leverage those regional attributes to spur economic growth by utilizing the basin’s CORE-CM resources as well as other minerals and waste streams.

Projects will also identify regional infrastructure needs, economic challenges and supply chain gaps that must be addressed to successfully use those CORE-CM strategies to promote economic growth and create jobs.

An initial evaluation will be conducted to identify:

- Existing basinal industries and businesses, their energy needs and infrastructure.

- Basinal infrastructure available to mine or access coal or waste streams and transport these materials to basinal locations for further processing.

- Currently available or needed REE and CM mining and raw material refining infrastructure.

Additional information that may be needed to complete the analysis of the technologies and infrastructure available to mine or access coal, coal byproducts, waste streams, or alternate source materials, and transport these materials to current (or future) facilities that refine these raw resource materials into feedstock materials.

The results of the Basinal Strategies for Infrastructure, Industries and Business Assessment effort will serve as the basis for the development of an initial Basinal Business Commercialization Plan that will be completed in subsequent phases.

The initial Basinal Infrastructure, Industries and Business Assessment will begin development though the collaborative effort and expertise of coalition members across various technology supply chains during Phase 1.

As a commercialization plan, effort may address:

- The integration of current and possible future industries that utilize (or may potentially utilize) coal, coal-based resources and regional wastes as process feedstock materials; or that utilize REE and/or CM as materials incorporated into intermediate products such as magnets, batteries, sensors, lasers, phosphors fluorescents, catalysts and the like; or that further integrate these intermediate products into end products such as industrial gas and wind turbines, sonar and satellite communication and guidance systems, structural aircraft components, frictionless bearings, smart missiles and the like.

- The potential economic impact and challenges of not only producing REE, CM and high-value, nonfuel, carbon products within each specific U.S. basin, but also transport requirements for the development of environmentally safe and sustainable projects, businesses and industries.

- Infrastructure needs, potential business/industry integration, economic challenges and supply chain gaps that need to be addressed to promote economic growth and create jobs.

- Critical needs to realize the full economic value of the basin’s resources for producing and utilizing REE, CM, and high-value, nonfuel, coal products, and/or alternate non-coal-based resource materials.

4. Technology Assessment, Development and Field Testing

CORE-CM projects will assess technology gaps across the full CORE-CM value chains for their basins, including: (1) innovative and sustainable mining techniques for coal and other basinal minerals; (2) processes to separate and purify REE and CM; and (3) technologies to incorporate coal-derived carbon, REE, and CM into value-added intermediate and end-use products. Both conventional and innovative products should be considered.

Projects will also formulate research strategies in Phase 1 to develop CORE-CM technologies to fill the identified technology gaps and to field test technologies to enable commercialization. An initial Technology Assessment, Development and Field-Testing Plan will be developed during Phase 1.

In this plan,

- SOTA and existing basinal technologies will be identified.

- Technologies will be assessed that address various segments of supply chains, from upstream exploration and characterization to innovative conventional and unconventional mining, beneficiation, separation and purification processes utilizing regional resources (coal, coal by-products and waste streams such as refuse, tailings, ash, acid mine drainage, and/or alternate non-coal materials).

- New technology may be identified that potentially results in enhanced environmentally benign processing, a reduced process footprint, or reduced overall operating costs within a basin. An example of new technology is, but is not limited to, unconventional mining practices such as horizontal drilling.

- New technology areas may result through the integration of current SOTA technologies with basinal host sites or industrial processes. For example:

- The integration of REE and CM extraction, separation and recovery at the coal mine site.

- The integration of REE and CM extraction, separation and recovery at carbon capture facilities (e.g., use of CO2 for mineral processing and recovery).

- New technologies may address the processing of alternate materials such as unmineable coal, and the like, to: (1) extract, separate and recover REE and CM; or (2) incorporate coal-derived carbon, REE and CM into value-added intermediate and end-use products.

In the initial Technology Assessment, Development and Field-Testing Plan, technical information gaps will be identified. The Technology Assessment, Development and Field Testing Plan will serve as the basis for the development of strategies that will be implemented in subsequent phases of the Carbon Ore, Rare Earth and Critical Minerals (CORE-CM) Initiative for U.S. Basins project, for advanced technology development and potential field testing and validation.

Notably, the technology gaps and proposed technology solutions will be specifically developed based on the unique characteristics of the basin, resources contained within that basin, and businesses and industries that currently exist (or may be developed in the future) in that basin.

5. Technology Innovation Centers

CORE-CM projects will formulate plans for technology innovation centers that will be developed and operated by basin-specific public-private partnerships. If implemented in subsequent phases, the technology innovation centers will provide a centralized and consistent platform to develop and validate CORE-CM technologies at laboratory-scale, including technologies that utilize advanced manufacturing techniques.

In Phase 1, coalitions will begin to address and propose, if applicable, the establishment, focus, organizational involvement and potential management of technology innovation centers within their basin. Each technology innovation center will advance the unique characteristics of its basin-specific geographic location, its contained coal and non-coal-based resources, as well as existing or potential future business and industrial opportunities, and the like.

The primary purpose of technology innovation centers will be:

- To accelerate research that will enable commercial deployment of advanced processing and production of REE, CM and high-value, nonfuel, coal products.

- To support engagement of public-private partnerships and basinal industries to advance new and innovative technology development as well as the potential for new product production.

- To advance opportunities for the education and training of the next generation of technicians, skilled workers, and STEM professionals. Technology innovation centers will include, but not be limited to, advancements in the areas of mining, beneficiation, processing and purification for domestic production of REE and CM. Technology innovation centers focused on high-value, nonfuel, carbon products will be based on basin-specific industries, manufacturing capabilities, and products.

In Phase 1, an initial Technology Innovation Center Plan will be developed that discusses the potential type of technology innovation center that is envisioned for the basin-specific CORE-CM Initiative for U.S. Basins project. This initial plan will discuss how the technology innovation center will potentially integrate the basin’s natural resources, infrastructure, industrial needs, and waste stream reuse opportunities.

To some degree, the technology innovation centers may be modeled after:

- The National Coal Council (NCC), Carbon Advanced Material, Manufacturing and Production (CAMP) Centers with expansion to include REE and CM.

- The National Carbon Capture Center (NCCC) providing a host site for field validation and scale-up of processing and purification technologies.

6. Stakeholder Outreach and Education

CORE-CM projects will formulate and implement plans for stakeholder outreach and education that are necessary to support CORE-CM economic development activities.

Plans will include the development of best practices as well as education and training for technicians, middle-skills workers, and STEM professionals. Plans for stakeholder outreach should include exploring potential collaborations with other R&D projects funded by DOE that are relevant to the CORE-CM Initiative, especially if those projects have a nexus with the basin of interest. Plans for collaborations between CORE-CM projects and other DOE-funded projects could expedite technology transfer and commercialization.

Initial Stakeholder Outreach and Education Plan should include:

- Workforce training and education.

- Open workshops and forums to engage and disseminate information to stakeholder industries, such as mining companies, power plant operators, oil and natural gas companies, and entrepreneurs throughout the basin, as well as to the general public and potential future workforce personnel, addressing technical and non-technical challenges of CORE-CM projects being conducted in their basin.

- Open workshops and forums that address technology transfer between basinal businesses and industries. This is viewed as being essential to ensure that the full potential of the basin’s coal-based and alternate material resources can be realized.

- Engagement with tribal, federal, state, local governments, and non-profit/nongovernmental groups to provide information on technology development, environmentally sustainable pathways and economic potential within their basin for production of REE, CM and high-value, nonfuel, carbon products. At the conclusion of Phase 1, the coalition will have acquired and analyzed available data, and will have determined where the data gaps are for assessments of both the (1) potential basinal resources, and (2) the economic, industrial, and infrastructure status of the basin.

- This information will inform and may direct the efforts of Phase 2 projects.

Phase 2: Completion of CORE-CM Basin Assessments and Development and Initial Implementation of Strategic Plans

Based on the foundational work completed in Phase 1, projects selected for Phase 2 will perform R&D to complete initial assessments, formulate strategies and begin to catalyze regional economic growth and job creation by realizing the full potential value of CORE-CM resources as well as other minerals and waste streams.

The Phase 2 effort will include, but may not be limited to:

- Implementation of R&D plans prepared in Phase 1 to fill information gaps in the initial assessments of CORE-CM resources and regional waste streams.

- Based on the results of the Phase 1 Basinal Strategies for Infrastructure, Industries, and Business Assessment, the formulation of strategies to integrate and leverage regional infrastructure, industries, and businesses to spur economic growth by utilizing the basin’s CORE-CM resources as well as other minerals and waste streams. Strategies should address the regional infrastructure needs, economic challenges and supply chain gaps identified in Phase 1. Phase 2 may also include implementation of the first stages of those strategies.

- Formulation of research strategies to develop and field test CORE-CM technologies to fill the technology gaps identified in Phase 1. Phase 2 may also include implementation of the first stages of those strategies.

- Updating Phase 1 plans for technology innovation centers that will be developed and operated by basin-specific public-private partnerships to provide a centralized and consistent platform to develop and validate CORE-CM technologies. Phase 2 may also include implementation of the first stages of those plans.

- Updating Phase 1 plans for stakeholder outreach and education that are necessary to support CORE-CM economic development activities. Phase 2 may also include implementation of the first stages of those plans.

- Preparation of a Workforce Development Plan for the training of the next generation of technicians, skilled workers, and STEM professionals, including scientists and engineers, for securing domestic materials and component production. This will include integration of accredited mining schools and other academic institutions, training and workforce development organizations, and National Laboratories within the basin being proposed. The plan will address the training needs and plan to develop and implement training for (1) technicians, (2) skilled workers, and (3) STEM professionals (including scientist and engineers).

Phase 3: CORE-CM Strategic Plan Implementation

Building on the work completed in Phases 1 and 2, projects selected for Phase 3 will further implement the strategies and plans created in Phase 2. The Phase 3 effort will include, but may not be limited to:

- Continued implementation of research strategies to develop and field test CORE-CM technologies.

- Continued implementation of plans to develop and operate technology innovation centers.

- Continued implementation of plans for stakeholder outreach and education that are necessary to support CORE-CM economic development activities.