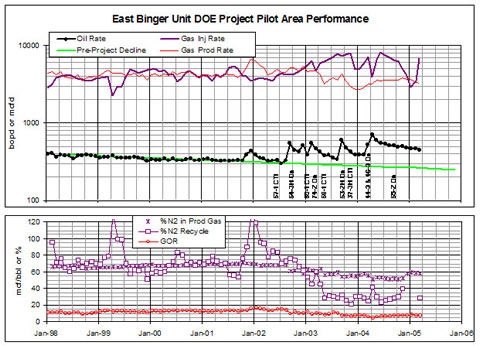

The East Binger (Marchand) Unit has been under miscible gas flood since unitization in 1977, first with flue gas and then with nitrogen. As with any flood, the injected fluid finds its way to producing wells (cycling) and must be handled. This flood was no different, except that the degree of cycling was high for the level of recovery. Initial review indicated the injected nitrogen was overriding the oil (gravity segregation) and moving to producers without mixing with and swelling the oil. It was believed that by placing horizontal producing wells at the base of the reservoir, miscibility could be improved and cycling reduced.

Project Results

Through the process of evaluating the benefits of horizontal wells in this setting, a greater understanding of the reservoir flow mechanisms has been obtained, allowing further development and improved recovery for the field. This geologic and reservoir setting, combined with the recovery mechanism employed, has proven to be more appropriate for vertical well development.

Based on results achieved, additional drilling beyond the scope of the original project has been completed. Project development work has added 200-300 barrels of oil per day to field production, roughly doubling production in the project area.

Binger Operations has completed the following:

- Drilled and completed three horizontal and seven vertical wells.

- Converted five wells to injection service.

- Completed modeling and fluid flow characterization work to identify critical fluid flow mechanisms.

- Evaluated over 200 gas samples to monitor gas cycling and the effects of producer-to-injector conversions.

Benefits

Three horizontal wells have been drilled into the Pennsylvanian Hoxbar formation of the Eastern Anadarko Basin, where previously only one such well had been drilled. Drilling difficulties were encountered and overcome. Although these technologies were not proven to be the most cost-effective for this field-in large part due to the recovery mechanism employed-they very likely will be the most cost-effective drilling technique in similar reservoirs with different recovery mechanisms. The lessons learned here will thus benefit industry, the State, and the general public through improved oil recovery.

In addition to the development of horizontal drilling practices in this area, the State and general public also will benefit from the improved understanding of the nitrogen flood underway in the East Binger Unit. With this improved understanding, the operator will apply additional knowledge to increase economic oil recovery from the field, providing monetary benefit to the State and local tax bases. The public also benefits through improvement in the labor market.

Project Summary

Project researchers have:

- Improved understanding of flow mechanisms in the Pennsylvanian Hoxbar formation of the Eastern Anadarko Basin.

- Successfully drilled and completed three horizontal wells in the Pennsylvanian Hoxbar formation of the Eastern Anadarko Basin, in which only one horizontal well had previously been drilled.

- Tested the viability of horizontal wells in a tight sandstone formation under nitrogen miscible flood.

Through the process of implementing the project, it was determined that the initial assumptions of flow mechanisms in the reservoir were largely incorrect. Directional flow driven by fracturing-not gravity segregation-appears to be the primary flow mechanism. With this improved understanding, methods to improve recovery are being implemented.

Horizontal well development was tested and found to be economically inferior to vertical well development. Based on the newly identified reservoir flow mechanisms, the optimal pattern configuration is a line drive, with lines of injectors and producers oriented in line with the direction of natural and hydraulic fracturing. As such, horizontal wells should be drilled along this line. Due to the low rock quality, all wells-including horizontal wells-must be fracture-stimulated to be productive. The optimal flood pattern configuration, combined with the need to fracture-stimulate, makes vertical infill well development economically superior to horizontal infill well development.