In California stranded gas, defined as gas that cannot qualify for commercial pipelines, has become a major problem, as it is inhibiting, or causing the early abandonment and loss of, domestic oil production. Traditional solutions to the stranded gas problem have been to either flare the gas, which adds to air quality problems without receiving any beneficial use from the gas; using valuable electrical energy to reinject the associated gas that must be re-produced later; or shutting down the oil production, leading to early abandonment of the oil well and thereby leaving the valuable resource in the ground. The Distributed Generation/Offgases project is developing the technology and expertise needed to turn this waste by-product into electricity, using a fuel previously considered unusable and uneconomic to produce.

Results

The project has demonstrated that distributed generation using waste or stranded gas from oilfields as a fuel is a viable and environmentally clean solution to disposal, reinjection, or abandonment of gas associated with oil production.

Benefits

This project seeks to add 75,000 barrels per day of domestic oil production within the next 10 years by preventing the waste of valuable oil resources through premature plugging and abandonment, or shutdown, of marginal oil wells due to economic and regulatory constraints. Based on an analysis by COPE, 40-60 percent of today’s cost of oil production and delivery is the cost of electricity. The objective of this project is to increase oil production by utilizing flared and shut-in gas from California’s oilfields to generate valuable low-cost electricity, displacing high-cost grid power. A successful project will extend the productive life of marginal oil wells and thereby aid in reducing our Nation’s reliance on uncertain foreign oil sources. Additional benefits include reducing our foreign trade deficit, lowering unemployment, reducing greenhouse gases and NOx emissions, and generating additional revenues for local, State, and Federal governments.

Summary

Project highlights include the following:

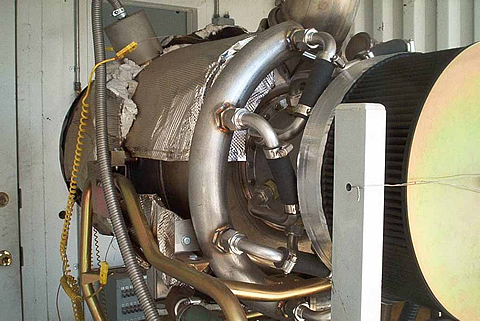

- The High-BTU project has enabled the return to production of a three-well marginal oilfield. This oilfield initially produced about 10 barrels per day of high-gravity oil but had been shut in for 8 years because the operator had no means to handle the natural gas associated with the oil being produced from the field. After reworking the wells, production increased to 23 barrels per day. Gas production was estimated at about 9,000 SCF per day of 1,650-BTU/scf gas. The researchers chose a Capstone 30-kW microturbine, using a horizontal scrubber to remove the produced water and a small compressor to achieve the line pressure needed by the turbine.

- The Medium-BTU project has returned an idle 19-well marginal oilfield back to production that is now capable of producing about 150 barrels of oil per day and had been at risk for abandonment because the operator had no outlet for the stranded gas production. The project performers chose three Capstone 30-kW microturbines for power generation, added a large compressor to achieve the pressure needed for the microturbines, a vertical scrubber to remove associated liquids, and a small refrigeration dryer.

- The Harsh Gas project is expected to bring a marginal oilfield into air quality compliance, eliminating or greatly reducing an oilfield flare. Hydrogen sulfide (H2S) is being scrubbed from the gas using a patented sulfur-treating system. An IR 70-kW microturbine is used to generate the electricity through an interconnect permit with Pacific Gas & Electric. There are two segregated streams of gas, one containing about 6,000 ppm H2S and the other sweet (containing no H2S). This allows researchers to test various concentrations of H2S.

- The Ultralow-BTU project is to utilize new technology—the ability to burn gas that was previously incombustible. The associated gas currently being produced is being spiked with 1,000-BTU commercial pipeline-quality gas so it can be flared, thereby also wasting the commercial pipeline quality gas. A 30-kW Flex microturbine is planned to generate the electricity. Researchers are to test the Flex turbine’s ability to handle this low-BTU gas in the field along with the durability of the catalyst used in the combustion process.