The information from the MWD sensors in the bottomhole assembly must quickly be relayed to the drill operator for real-time navigation of the drill bit. One common method of transmitting downhole sensor data to the surface is by sending extremely low-frequency (e.g., 40 Hz) signals though the layers of the earth to reach a receiver antenna located on the surface, typically some distance from the drill string. This method is inherently slow because of its low frequency of operation and narrow bandwidth. The other common communication method uses wirelines or fiber optics embedded in the drill pipe to provide high-speed communications with the topside receiver. This is generally expensive. The DTS develop dby this project is designed to be a cost-effective alternative to these MWD communications methods.

Currently, the location of the drill bit in the hydrocarbon reservoir relative to the top and bottom boundaries of the reservoir during horizontal drilling s determined using gamma ray, neutron, and resistivity sensors. No tool is available to let the horizontal drilling operator know the distance between the drill bit and the bounding strata of the reservoir in real time. DSR eliminates this deficiency.

Results

Stolar Research Corporation (Stolar) has successfully developed pre-commercial prototypes of two technologies, the Stolar Data Transmission System (DTS) and the Stolar Drill String Radar (DSR), for application in coiled tubing drilling environments. These technologies are also applicable to conventional segmented pipe drilling.

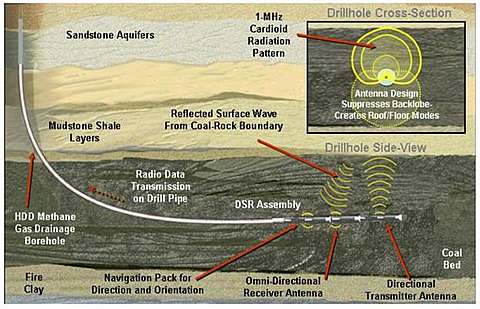

To track the boundary rocks in a hydrocarbon reservoir during directional drilling, a prototype digital signal processing-based Drill String Radar™ (DSR) capable of coherent detection of radio waves has been designed and fabricated. The DSR system allows for the MWD guidance and navigation of coiled tubing. The modulation scheme can be changed to accommodate the geology (e.g., coal or oil) under investigation, and the new DSR system allows the modulation scheme to be modified “on the fly.” The modulation schemes required for various target depths are being investigated.

The DSR is based on the coherent detection of reflected, continuous-wave signals. The operating frequency and the dynamic range of the DSR depend on the electrical properties of the host rock. Because of coal’s high resistivity, higher operating frequencies can be used in a coal seam than in an oil reservoir. An algorithm for processing the data from a stepped-frequency radar system has been developed that reduces the clutter effects. This system’s design range for boundary rock detection is 15 meters.

A data transmission system (DTS) has been developed that uses only the outer surface of the drill pipe to propagate communications signals. The DTS uses frequency-shift keying modulation of 91.5-kHz signals. The system requires no added wires to the drill pipe. Radio waves are inductively coupled to and from the drill pipe skin using loop antennas. The radio waves propagate along the bare metal skin of the drill pipe. The system takes advantage of the natural waveguide properties of the hydrocarbon seam; the entire drill rod and the immediately surrounding layers of rock become the data transmission channel. The DTS transmits data collected by the DSR at a rate of 2,400 bits/second. The system also is equipped with a downhole navigation package (three-axis magnetometer and accelerometer) that provides bottomhole assembly orientation data that complements the data from the DSR. The DTS is capable of two-way communications between the surface and downhole instruments.

The importance of these two technologies has been recognized nationally. For example, R&D Magazine selected Stolar’s DSR and DTS technologies for R&D 100 Awards in 2005 and 2006, respectively. These prestigious awards are given to designate the 100 most technologically significant products of the year.

Benefits

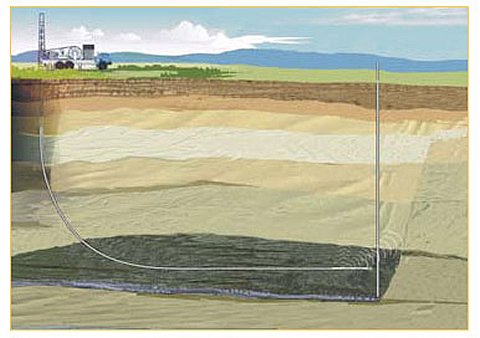

DSR and DTS allow real-time navigation and imaging during exploration using coiled tubing drilling (CTD). With CTD, there is minimum land disturbance, less wastewater production, and fewer drillholes. The horizontal laterals that can be drilled using CTD and DSR improve the recovery efficiency of shallow production wells. Through real-time navigation, the operator can eliminate the expensive practice of sidetracking in horizontal drilling. DSR directional drilling avoids the need to stimulate vertical coalseam wells using cavitation.

Summary

With an in-situ DSR system operating at 20 kHz, the resistivity of an oil-saturated limestone deposit was found to be 150 ohm-m. In an oil reservoir, the conductive nature of rocks allows only the propagation of low-frequency signals, which precludes the use of conventional radar modulation schemes that employ wide bandwidths. To track the boundaries in an oil reservoir, DSR operates at 1 MHz with multiple transmitter and receiver antennas configured as compound antennas to provide directionality and spatial diversity.

A prototype DSR system has been designed and fabricated that can detect and map the boundary rocks of a hydrocarbon reservoir. The prototype 800-kHz system, which employed a transmitter-receiver pair of loop antennas, was tested in a deviated borehole. Test results showed that the resonant frequency and transmission loss can be used in tracking an air-soil boundary in conductive soil.

A prototype radar system was tested inside a coal mine. Test results were inconclusive but indicated a need to improve the algorithm for suppressing the reflections of near-field targets while enhancing the reflections of more distant targets.

Researchers also have partially mapped the directional field of the DSR’s compound antennas in shallow, vertical, uncased boreholes. Test results indicated that a directional field was formed, but better phase control between the elements of the compound antenna is needed.

A proof-of-concept DTS prototype suitable for propagating communications signals along the outer skin of a metal drill rod has been designed and fabricated. During aboveground tests that simulated borehole conditions, the system was successfully tested over 1,700 feet of pipe. During underground testing over 500 feet of pipe inside an uncased, water-filled test hole in Deer Creek coal mine in Utah, the downhole transmitter sent bottomhole assembly orientation data to the topside receiver. The signal-to-noise ratio at the receiver for the one-way communications test was better than 30 dB.

A more robust DTS preproduction prototype, capable of data communications under actual drilling conditions, has been designed and fabricated. It focuses on strength, fluid flow, abrasion resistance, integrated power production and distribution, explosion proofing, intrinsic safety, user and maintenance friendliness, modular design, upgradeability, scalable design, antenna accuracy and optimization, vibration dampening, durability, economy, and immunity to radio frequency interference (RFI).

Researchers have designed an explosion-proof battery pack that integrates a turbine generator and facilitates power distribution and software control of power functions.