Small downhole PDMs have limited power output and are prone to stall when run with aggressive polycrystalline diamond compact (PDC) bits. PDMs are designed to operate at a limited pressure differential on single-phase, water-based mud. Also, as lateral reach increases, the thrust available for mechanical drilling drops due to coiled tubing friction and helical buckling in the borehole. High-pressure fluid jets operating at 70 MPa (10,000 psi) have proven effective at cutting a wide variety of rock formations, particularly oil-bearing shales and sandstones. High-pressure jet drilling also dramatically reduces the torque and thrust required for drilling, thus increasing ROP and lateral reach. Unfortunately, coiled tubing fatigue life diminishes rapidly at pressures required for effective jet drilling of rock.

Results

In project results to date for the jet drilling BHA, researchers have: 1) completed review of the jet drilling system commercial market, configuration, and sizing, including integration with microhole-sized CTD equipment; 2) completed numerical modeling of gas separator, intensifier, jet drill, and circulation in coiled tubing; 3) completed design and fabrication of prototype gas separator, downhole intensifier, and jet drill; and 4) completed four rounds of testing in the project performer partner’s simulated downhole test facility using a fluid mixture of nitrogen and water.

Test results show that the BHA produced 49 kW (66 hhp) at the nozzle, demonstrating that the jet drilling BHA can deliver more power downhole than a 2.875-inch positive displacement downhole motor (PDM). The prototype BHA drilled a section of aged cement in 4.5-inch tubing at a rate of 100 ft per hour. The BHA has also endured 5 hours of continuous operation at the test facility. Results to date for the prototype gas separator connected to the inlet of a PDM are 1) that the cement drilling tests confirmed that the commingled gas was removed ahead of the PDM, and 2) that the PDM performed as it would on plain water.

Benefits

The economic benefits of the high-pressure waterjet microhole CTD system are derived from both increased capabilities and reduced drilling costs. This drilling system will be able to drill deeper and farther in deviated wells than current coiled tubing technology because of 1) increased downhole power, 2) the ability to drill underbalanced, 3) improved cuttings transport, 4) reduced tendency to stick in the hole, and 5) increased drilling efficiency in pressure-sensitive shales. Other economic benefits result from the decreased hole size. When the volume of a 3?-inch diameter hole is compared with that of a conventional 8½-inch diameter hole, 83 percent less fluid is required to fill and circulate the microhole. The gas separator connected to the inlet of a PDM will reduce PDM stator damage and smooth out operation during underbalanced drilling operations.

Summary

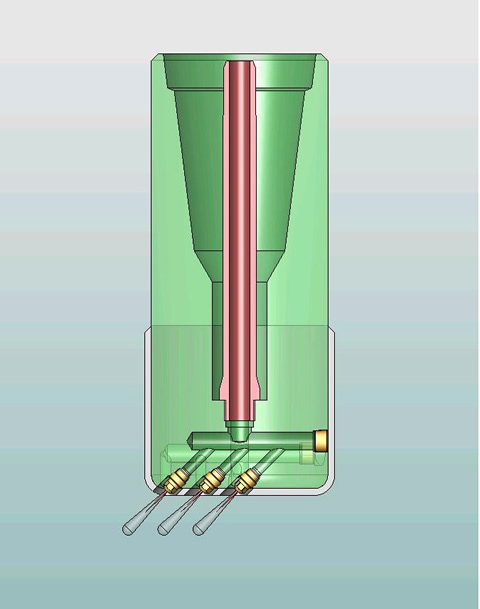

This project addresses these difficulties with a downhole intensifier (DHI) that boosts the hydraulic pressure available in conventional CTD to the level required for high-pressure jet erosion of rock. The first phase of the project consisted of three major tasks: 1) analyze the CTD system to define operating parameters for the drilling assembly, 2) design the downhole intensifier BHA, and 3) fabricate and test components in a test facility.

A review of high-pressure jet drilling and mechanically assisted jet drilling was carried out to define the BHA configuration and DHI performance specifications for CTD applications. Two BHA configurations were evaluated: 1) mechanically assisted high-pressure jet drilling with the DHI deployed below a PDM drill motor and 2) high-pressure jet drilling with the DHI deployed upstream of a rotary jet drill.

The analysis showed that high-pressure jet drilling with a PDM drill motor and DHI should allow drilling at three to five times conventional drilling rates. However, a drill motor was not found that reliably operates at the 28-35 MPa (4,000-5,000 psi) above ambient pressure as necessary for effective DHI performance. Altering seals and bearings of a PDM for this service was found to be impractical within this project. Accordingly, a high-pressure rotary jet drilling head is used in lieu of a PDM. A proprietary integrated turbine motor was also considered.

Analysis showed that underbalanced jet drilling with commingled gas and water not only reduces formation damage, the low-density fluid in the borehole enhances the effective range of the jet and increases the power available downhole. To take full advantage of these benefits, a downhole gas separator is used to remove gas from the fluid before being intensified and discharged through the nozzles. The gas separator also has applications in other two-phase fluid drilling applications, particularly when used with a PDM.

The downhole intensifier, gas separator, and high-pressure rotary jet drill designs represent modifications of existing tools designed and built by the project performer and operated by its partner for coiled tubing scale milling. The jet drilling system is expected to provide sustained drilling rates of 80 ft per hour or more with a microhole CTD system, while providing over 100 hours of reliable motor operation.