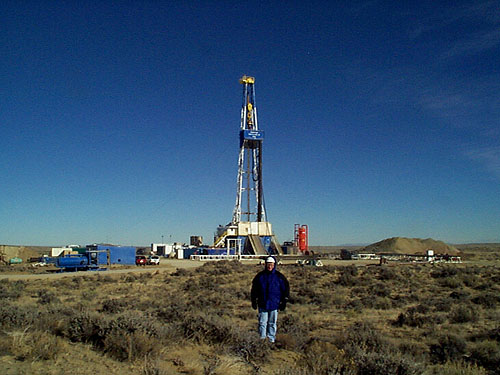

- One of the deepest horizontal tight gas sandstone wells in the world (14,950').

- Deepest horizontal cores in the world.

- Reduced the drilling time and expense for vertical wells deeper than 15,000' to less than half of the average time and cost encountered by industry during the last decade. This is critical to making the deep, vertical or horizontal tight gas sand wells a viable option.

- One of the highest gas flow capacities ever encountered in the tight-gas province of the Cretaceous Frontier formation in Wyoming (12 to 20 mmcfd).

- Geosteered 1750' of horizontal lateral within a 20' window.

- 400 open fractures intersected in 1750' of horizontal section.

- The initiation of ongoing plans for a horizontal drilling effort by industry to evaluate and exploit the previously unattainable resource.

- The well was placed on production on May 15, 1999. The initial rate was 13.6 MMCFD and produced 1.2 BCF of gas in the first 3 months of production. As of Nov 22, 1999, the well had produced at total of 2.2BCF of gas and the current rate is 9.5 MMCFD.

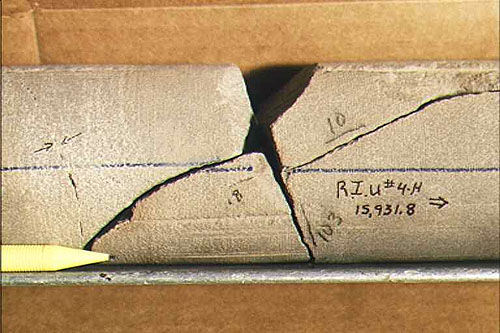

- 58.6 feet of core was recovered from UPR's Sidewinder #1H well on Nov. 10, 1999. This well is located approximately 1.5 miles to the east of the Rock Island 4H well. The core had a total of 41 visible fractures, of which 31 were open. The core was recovered at a deeper depth (15,493' - 15,499' TVD) than that of the Rock Island 4H well cores.

UPR selected a site designated as the Stratos site for the location of the proposed well. The site was located in Section 24, Township 22 North – Range 107 West (T22N-R107W), Sweetwater County, Wyoming. The site selection was based on regional geology and existing wells within the region. The most influential wells were the Blue Rim Federal #1-30 and the Blue Rim Federal #1-31. Core analyses from these wells confirmed matrix permeabilities of less than 0.1 millidarcy, however despite the low permeabilities, the Blue Rim 1-30 tested at 1.3 MMcfd from the Second Frontier sandstones. The cores also indicated dirty sandstone with less secondary quartz mineralization. It was thought that this relatively high flow rate from the very low permeability rocks most likely reflected the presence of natural fractures in the Second Frontier reservoir.

Upon DOE approval of the proposed well site, UPR proceeded with Phase 2. The Stratos Federal #1 well was drilled through the Second Frontier to a total depth of 16,250 feet. In an effort to facilitate the fracture characterization portion of the project, the well was deviated starting at a depth of 13,872 feet on through the Second Frontier in an effort to increase the probability of intersecting one or more vertical fractures during drilling. The well encountered 8 gross feet and 4 net feet of fluvial channel sandstones and approximately 40 gross feet and 19 net feet of marine sandstones. Oriented cores were taken through the fluvial and marine sections of the Second Frontier to aid in the understanding of the reservoir and in designing the completion of the well. A total of 109.8 feet of core was retrieved from the well. Core porosities ranged from 3.3 to 7.3 % in the fluvial sandstones and from 3.5 to 11.4% in the marine sandstones. The unstressed horizontal permeabilities to air ranged from <0.01 to 0.25 millidarcies in the fluvial section and from <0.01 to 0.1 millidarices in the marine. Open hole logs were also run to aid in the characterization of the reservoir. The vertical well was then cased and readied for testing.

Once the vertical well was completed, it was thoroughly tested and evaluated. The contract called for cased-hole stress testing, pre-frac well testing, mini-frac, and a main “Moxa-Type” frac. The stress tests and the pre-frac tests were performed and the results of these tests along with the various core and well log analyses demonstrated that the Second Frontier in the Stratos #1 well did not exhibit reservoir properties that would warrant the further expense of hydraulic fracture stimulations. Additional evaluation results also showed that the reservoir contained a massive clean sandstone cemented by secondary quartz with very few natural fractures, very little pronounced bedding, and very few hydrocarbon shows. The lack of open natural fractures was very detrimental to the well as an interconnected natural fracture system is needed in a low-permeability reservoir to make it economic. The few natural fractures that were identified in the cores were microfractures and were quartz-filled, therefore offering no passageway for the gas to flow. The Frontier formation as a whole in this well was very clean sandstone with very low porosity due to secondary quartz mineralization. Hydrocarbon shows were also scarce in the well and as a result the initial production from the well was only 20 Mcfd. As stated above, it was concluded from the testing results that even though the productivity of the Stratos well could be enhance by a hydraulic fracture treatment, the resulting production would not warrant the expense, as it still would only be in the few hundred Mcfd range. At this point, both DOE and UPR agreed that this was not an ideal location for a horizonal well, and that an alternate location should be sought.

During the time that the Stratos well was being drilled and in the months following, several wells were drilled through the Second Frontier on the east side of the Rock Springs Uplift. These wells were overpressured, and strong gas shows and cores taken from those wells contained both partially open and cemented natural fractures. One of those wells was the Government Union #4 well, which was drilled by Texaco for completion in a formation deeper than the Frontier formation. However, while drilling through the Frontier, the well had a very large gas show in the Frontier formation and core taken in the Frontier contained a very large open natural fracture. Texaco attempted to seal off the Frontier and complete the well in a deeper formation, however their efforts were unsuccessful. They eventually completed the well in the Frontier formation, where initial production from the well was 6 MMcfd and had continued at a steady rate. With this information known, UPR then proposed a site 1.5 miles to the northeast of the Government Union #4 as an alternate location.

Before approving the site, DOE was in a unique situation to integrate two research projects together. ARI had developed a geomechanical model under another DOE contract and was in the field testing phase of the project. DOE discussed with ARI the possibility of using the proposed UPR well location as one of their field test locations, to which ARI agreed. The significance of the geomechanical model is that it identifies high stress zones, which indicate a high likelihood of natural fractures being present. The importance of natural fractures was shown in the Stratos well and DOE wanted to be certain that natural fractures would be present in the new location. UPR was very cooperative in this ARI effort of model validation and the results indicated that there was a very high possibility of intersecting natural fractures at this proposed location. After reviewing the goemechanical results and the reservoir data from surrounding wells, DOE approved the well location.

UPR spudded the Rock Island #4H well on October 14, 1998. The vertical section was drilled to a depth of 14,487 feet at which point the vertical section was logged and cased. The well was then kicked-off to go horizontal. Drilling was very slow through the turn of the well, however very few problems were encountered. Once the well had penetrated the upper marine section of the Frontier, core was taken in the well. Drilling then proceeded at an approximate angle of 80-85 degrees from vertical to follow the formation dip. The upper marine section was approximately 15 feet thick and was separated from the lower marine section by a 4 foot coal/shale stringer. The lower marine was approximately 21 feet thick. Both the upper and lower marine sections dipped to the northeast at an 85 degree angle. The horizontal section crossed several structural faults during the drilling. UPR was able to identify these faults and keep the wellbore proceeding in the formation only by the use of their patented geosteering technology. The well was drilled to a total measured depth of 16,784 feet and a true vertical depth of 14, 953 feet. This included a lateral section of 2,297 feet, which was completed in the marine section of the Frontier formation. The lateral section was just short of the planned 2,500 feet due to a structural fault that dropped the formation approximately nine feet below the wellbore. During the drilling, 79 feet of planned 90 feet of horizontal core was retrieved from the well. It was determined that this was the deepest horizontal core ever recovered in the U.S. The core contained several open natural fractures and a FMI log identified over 400 open fractures in the horizontal section. The cores confirmed the accuracy of the FMI logging in these highly fractured formations. The initial production for the Rock Island #4H well was 13 MMcfd and the well has produced over 4.5 BCF in the first 18 months of production. The well is still on production and is currently producing 6 MMcfd. These production numbers prove that this low-permeability resource can be produced economically.

At the completion of the Rock Island #4H well, it was determined that there was approximately $250,000 uncosted remaining in the contract. UPR approached DOE with a proposal to take extra logs and core in two new wells they had planned. The additional data would aid in the regional reservoir characterization of the Frontier formation. The proposed logs and core were above what UPR would normally take during a drilling operation. UPR proposed to cost share the additional logs and core at a 50/50 rate, to which DOE agreed. Logs were then taken in two additional wells, Sidewinder #1H and Sidewinder #2H, and core was retrieved from the Sidewinder #1H. This data was used to further characterize the region.