Multi-Functional Distributed Fiber Sensors for Pipeline Monitoring and Methane Detections

Project Number

DE-FE0029063

Last Reviewed Dated

06/25/2020

Goal

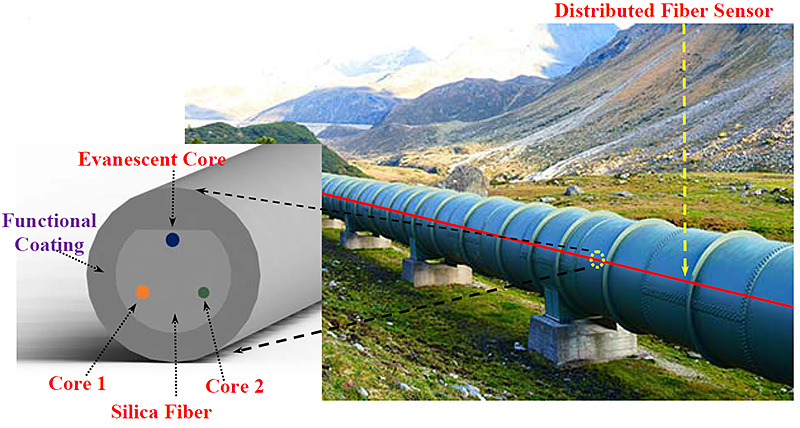

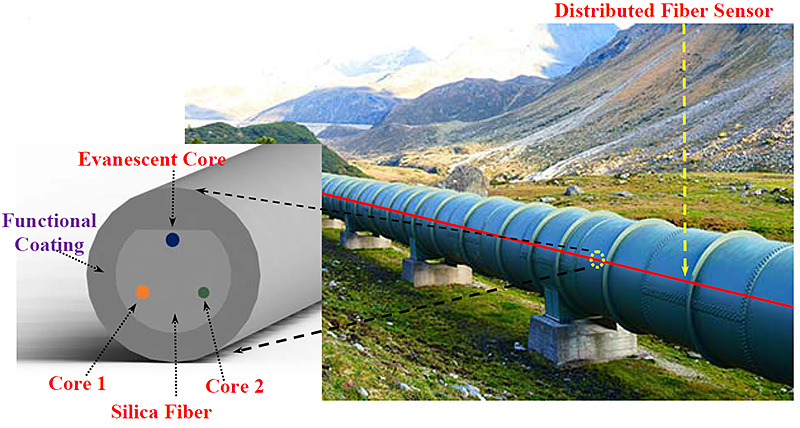

The goal of the project is to develop a new distributed fiber optical sensing technology that can perform multi-parameter and real-time measurements of natural gas pipeline systems including direct measurements of methane concentration across long interrogation distances (e.g., up to 100 km) with spatial resolution of 1 meter per measurement.

Performer(s)

University of Pittsburgh (Pittsburgh, PA) and Corning, Inc. (Corning, NY)

Background

The large-scale extraction and utilization of natural gas creates significant challenges on methane leakage. This problem is exacerbated by aging gas utility delivery systems including interstate high pressure pipelines and storage facilities. As a potent greenhouse gas, leaking methane could negatively impact US efforts to reduce carbon emissions.

The scope of this project involves development of a multi-core optical fiber for simultaneous temperature, strain and optical methane absorption measurements, development of a functional polymer coating for methane detection, and ultimately, integration and testing of a fully-functional distributed fiber optical sensing technology for real-time measurement of methane emission from natural gas pipeline systems.

Research to be performed is divided into three major tasks that shall be conducted over a three year period and is designed to achieve the research objectives in the most efficient and cost‐effective way. These include:

- Development of a multi-core fiber that can perform distributed temperature, strain, and absorption measurements in one fiber.

- Development of new functional polymer materials which can be coated on the fiber during the fiber manufacturing process. This task is further sub-divided into two aspects. The first sub-task will be to design, synthesize, and test curable functional polymer materials that swell sufficiently in the presence of methane such that strain-based distributed sensing can be achieved. Due to methane’s low solubility compared to most other organic substances, the second sub-task will investigate organic and inorganic solutes that are dissolvable in the elastic polymers in order to enhance the polymer’s methane affinity, thereby supporting improved absorption-based distributed sensing.

- Fabrication and testing of the new application-specific fiber and fiber coating designs for natural gas pipeline monitoring.

Impact

Distributed fiber sensing technology is generally limited to monitoring a single physical parameter, such as temperature or strain. This research will transform the technology by developing new multi-core optical fibers and functional fiber polymer coatings capable of monitoring both physical and chemical parameters across the entire fiber length with high spatial resolution. In addition, by changing polymer fiber coating compositions, the optical fiber can be designed to respond to different chemical species in gaseous or liquid phases beyond methane. This will dramatically increase adaptability of distributed fiber sensors for other applications beyond natural gas pipelines, such as monitoring of oil infrastructure, hydrogen facilities, CO2 and carbon storage, and water pollution.

Accomplishments (most recent listed first)

- Completed development of distributed fiber methane sensors based on intrinsic Fabry–Pérot interferometer chemical sensor array using spatial optical frequency domain reflectometry.

- Completed development of the methane-sensitive elastic polymer and Metal Organic Frameworks (MOFs) fiber coating on D-shape fiber and multi-mode fibers that supports Optical Time Domain Reflectometry (OTDR) distributed sensing scheme. System is approaching a methane detection sensitivity 0.1%.

- Established a fiber-optical wavelength modulation spectroscopy setup to interrogate methane using the methane-sensitive elastic polymer and MOFs coated fibers.

- Established a fiber-optical wavelength modulation spectroscopy setup to interrogate methane using the polymer-coated optical fibers.

- Tested polymer coated optical fiber to be responsive to methane gas.

- Prepared free-standing films consisting of functional polymers with and without MOF (Metal Organic Frameworks). These functional polymers have been successfully coated on the surface of the multi-mode fibers and D-shape fibers, and setup has also been fabricated for strain-based sensing and power loss sensing.

- Attempts have been made to dissolve and integrate MOF with an enforced cage structure within the appropriate size for CH4 molecule trapping into polymer matrices. The MOFs may be able to absorb methane with great quantity and specificity. MOF have been successfully synthesized and incorporated into polymer samples to form the uniform emulsions.

- Two kinds of UV curable system for absorption-based measurements and elastic polymer for strain-based measurements have been successfully fabricated. Controls on the refractive indices of both kinds of polymers were successful. The refractive index of the synthesized polymeric materials is less than 1.45, which is adequate for performing both evanescent absorption measurements and strain-based measurements.

Current Status

Current efforts are focused on developing reel-to-reel fiber sensor fabrication setup to produce sensing fiber up to 1000-meter long to achieve TRL5 for the fiber sensors and performing testing of distributed sensors using both methane absorptive and methane non-absorptive wavelength to determine appropriate laser wavelength for the sensor interrogation system.