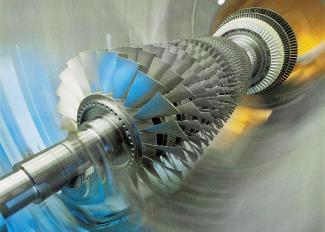

NETL scientists are advancing the development of high-entropy alloys (HEAs) that can withstand significantly higher temperatures and extreme stress to enable gas turbines to run with greater efficiency.

The development of these durable materials will not only enable industrial gas turbines to generate cleaner electricity using abundant domestic energy sources, they also may be used to manufacture the stronger components needed to build next-generation aviation turbines (jet engines) that require less fuel and produce fewer emissions.

As part of the Advanced Research Projects Agency-Energy (ARPA-E) Ultrahigh Temperature Impervious Materials Advancing Turbine Efficiency (ULTIMATE) program, NETL is partnering with the Oak Ridge National Laboratory and Carnegie Mellon University to advance the development of structural materials that can withstand the highest temperatures in a turbine, as well as the extreme stresses imposed on turbine blades.

The work could dramatically improve U.S. energy security. According to ARPA-E, a federal agency that advances high-potential, high-impact energy technologies, a 7% improvement in efficiency in natural gas turbines used for electricity generation represents an opportunity to save up to 15-16 quads of energy by 2050. One quad represents 293 billion kilowatt-hours, or the energy of 183 million barrels of petroleum, 38.5 million tons of coal or 980 billion cubic feet of natural gas.

ARPA-E estimates that improvements in turbines used for civilian aircraft represents another 3-4 quads of potential energy savings for U.S. air travel over the same time span.

NETL has focused on the development of HEAs — alloys that are constructed with equal or nearly equal molar quantities of five or more metals, combining the characteristics of individual elements into a superior substance. HEAs exhibit unique properties when compared to traditional alloys, including increased strength, wear-resistance, and corrosion- and oxidation-resistance — properties that increase the effectiveness of turbine hardware.

“HEAs can be used to manufacture more durable blades, vanes, nozzles, shrouds and other components so that natural gas-burning turbines can run at considerably higher temperatures while using less fuel to create more electricity and fewer emissions,” said Michael Gao, Ph.D., senior materials scientist, NETL.

“In the aviation industry, there is critical need for more efficient turbines using components manufactured with superior materials to achieve similar efficiencies and reduce fuel costs,” Gao said.

Temperature capability of turbine blade materials has improved steadily to 1100 ºC. At completion, the ULTIMATE project is expected to demonstrate a disruptive alloy and its advanced manufacturing for potential use in turbine blades for service at temperatures greater than 1300 °C (2372 °F).

NETL is advancing the use of an integrated computational materials engineering (ICME) approach in developing cost-effective HEAs for extreme environments. This approach and multiscale computational modeling and machine learning (ML) will help accelerate the design of new alloy compositions. Ground-breaking research at NETL validated the use of ML and data analytics to design next-generation alloys beyond the reach of experiments alone, saving time, money and materials.

In the first phase of the ULTIMATE program, which is scheduled to run for a maximum of 18 months, project teams will demonstrate proofs of concept for their alloy compositions, coatings and manufacturing processes through modeling and laboratory scale tensile coupon (sample) testing of basic properties.

In the second phase, to be conducted over a period of up to 24 months, approved project teams will investigate selected alloy compositions and coatings to evaluate a comprehensive suite of physical, chemical and mechanical properties, as well as produce generic small-scale turbine blades to demonstrate manufacturability.

NETL is well-positioned to serve as a leader in the ULIMATE program. The Lab maintains a complete alloy development research facility in Albany, Oregon, which includes a fabrication laboratory for prototyping alloy manufacturing.

The U.S. Department of Energy’s National Energy Technology Laboratory develops and commercializes advanced technologies that provide reliable and affordable solutions to America’s energy challenges. NETL’s work supports DOE’s mission to advance the national, economic and energy security of the United States.