An advanced solvent for post-combustion carbon capture developed through a partnership involving the University of Texas at Austin (UT Austin) and Honeywell is set for engineering-scale testing in October at the Technology Centre Mongstad (TCM), the world’s largest carbon capture test facility located in western Norway.

NETL’s expertise using science-based models, artificial intelligence and machine learning (AI/ML), data analytics, and high-performance computing to develop new, clean, efficient and affordable energy technologies was on full display in September at the 10th New York Scientific Data Summit.

Washington, D.C. — The U.S. Department of Energy’s (DOE) Office of Fossil Energy and Carbon Management (FECM) today announced $29 million for 12 research and development projects to fund two carbon management priorities—the conversion of carbon dioxide (CO2) into environmentally responsible and economically valuable products and the development of lower-cost, highly efficient technologies to capture CO2 from industrial sources and power plants for permanent storage or conversion. Accelerating the development of these technologies will advance the Biden-Harris Administration’s ambitious climate goals of achieving a carbon-neutral power sector by 2035 and net-zero greenhouse gas emissions by 2050 and help establish the foundation for a successful carbon capture, storage, and conversion industry in the United States.

A novel direct air capture (DAC) technology is being developed by Research Triangle Institute (RTI) International with funding and management support provided by NETL on behalf of the Office of Fossil Energy and Carbon Management (FECM). Through three collaborative research and development projects, RTI has selected a DAC sorbent material, completed initial testing of their air contactor design, and is now designing an integrated DAC process for field testing.

A team of researchers from NETL and academia have demonstrated the unique dynamic analysis capabilities available through the Lab’s Institute for the Design of Advanced Energy Systems (IDAES) to advance clean energy technologies.

NETL researchers developed an improved method for gasifying post-consumer plastic and biomass waste to generate clean hydrogen-rich syngas while reducing tar as an undesirable byproduct.

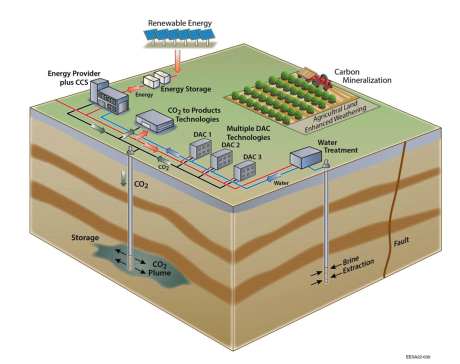

NETL has awarded and is currently managing 16 regional direct air capture (DAC) Hub projects throughout the country, putting into use the technologies developed by the Lab and partner organizations to address climate change.

NETL Director Marianne Walck, Ph.D., discussed how the Lab works to tackle climate change and helps to ensure a clean energy future as part of the Wilton E. Scott Institute for Energy Innovation Distinguished Lecture series at Carnegie Mellon University (CMU) in Pittsburgh, Wednesday, Sept. 25.

WASHINGTON, D.C. – The U.S. Department of Energy’s (DOE) Office of Fossil Energy and Carbon Management (FECM) today announced up to $4 million in federal funding to make clean hydrogen a more available and affordable fuel for electricity generation, industrial decarbonization, and transportation. Specifically, the funding opportunity will support research and development (R&D) projects that will expand the versatility and applicability of solid oxide fuel cell technology—a source of efficient, low-cost electricity from hydrogen or natural gas—with a focus on reversible solid oxide fuel cell (R-SOFC) systems. This technology has many energy efficiency and clean energy applications, including hydrogen production, hydrogen energy storage, energy conversion and storage for renewable and surplus energy, microgrids, combined heat and power, and more.

WASHINGTON, D.C. — The U.S. Department of Energy’s (DOE) Office of Fossil Energy and Carbon Management (FECM), in collaboration with DOE’s Office of Energy Efficiency and Renewable Energy (EERE), announced up to $19.5 million in federal funding to advance technologies that will help reduce costs for recovering critical minerals and materials from domestic secondary and unconventional sources. The projects will help restore the United States as a world leader in the extraction, separation, and refining of these materials—needed to produce solar panels, wind turbines, and other energy technologies, as well as components for defense systems and other electronics—while reducing our reliance on foreign supply chains.