When an autumn frost descends on southwestern Pennsylvania, NETL’s Thomas Tarka can sometimes detect an aroma in the crisp fall air that can only mean one thing.

A growing roster of technology companies from around the globe are partnering with NETL to unleash direct air capture (DAC) as a powerful tool in the fight to mitigate the climate crisis.

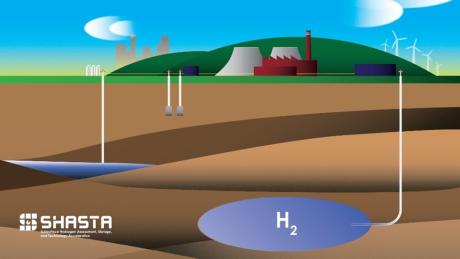

Researchers at NETL and the University of California San Diego have completed a series of studies that found hydrogen — a low-carbon fuel with tremendous potential to help the United States meet its climate change goals — can be stored in the subsurface without significantly altering the layer of protective shale caprock, which seals the storage reservoir and prevents the migration of the gas.

A recent analysis published by Stanford University included 24 current and former NETL researchers in the top 2% of global scientists, demonstrating the level of talent and expertise the Lab is bringing to bear on the nation’s decarbonization goals.

Researchers at NETL and their partners have received $1.7 million from the U.S. Department of Energy’s (DOE) Advanced Research Projects Agency-Energy (ARPA-E) to develop and field-validate H2-SMART — novel distributed fiber optic sensors with an artificial intelligence-driven model to locate and quantify hydrogen emissions from pipelines with enhanced accuracy and efficiency.

A research team consisting of private sector and academic partners and led by NETL is working on a new ultra-conductive carbon aluminum composite cable technology that could increase the electrical conductivity and strength of transmission cables leading to higher grid capacity and efficiency to accommodate future power generation demand.

WASHINGTON, D.C. — The U.S. Department of Energy’s (DOE) Office of Fossil Energy and Carbon Management (FECM) today announced more than $518 million to support 23 selected projects across 19 states that will fight climate change by developing the infrastructure needed for national decarbonization. The projects, funded by the Bipartisan Infrastructure Law, will provide for the development and validation of commercial large-scale carbon storage infrastructure to significantly and responsibly reduce carbon dioxide (CO2) emissions from industrial operations and power plants, as well as from legacy emissions in the atmosphere, while supporting good jobs and environmental priorities in local communities. DOE is also seeking information from stakeholders on carbon storage infrastructure needs prior to opening the next round of this funding opportunity.

WASHINGTON, D.C. — The U.S. Department of Energy’s (DOE) Office of Fossil Energy and Carbon Management (FECM), with DOE’s Hydrogen Fuel Cell Technologies Office (HFTO), today announced more than $58.5 million in federal funding for 11 projects to help develop a commercially viable carbon dioxide removal industry in the United States. The funding will support pilot projects and testing facilities to demonstrate and scale carbon dioxide removal technologies that reduce carbon dioxide (CO2) pollution by removing it directly from the atmosphere.

NETL is announcing that the U.S. Department of Energy’s (DOE) Office of Fossil Energy and Carbon Management (FECM) anticipates soliciting applications for additional projects similar to those solicited under DE-FOA-0002730. These projects would receive funding from the Bipartisan Infrastructure Law to conduct front-end engineering and design (FEED) studies that support and accelerate the planning for carbon dioxide (CO2) transport from anthropogenic sources to CO2 conversion or secure geologic storage locations. Carbon capture sources may include a combination of CO2 removal (e.g., direct air capture and biomass carbon removal and storage (BiCRS)), and point sources (e.g., industrial and power generation). All modes of CO2 transport (pipeline, truck, rail, barge, and ship), including any combination of transport modes, may be considered. If a solicitation is issued, it could be a reissuance of funding opportunity announcement (FOA), DE-FOA-0002730, or a new solicitation.

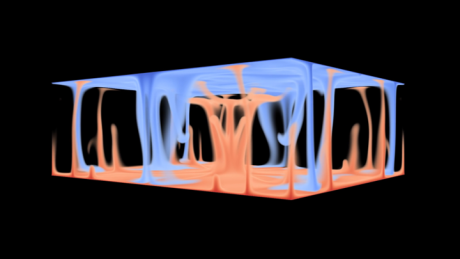

NETL and partner Cerebras Systems of Sunnyvale, California, have been awarded $8 million by the U.S. Department of Energy (DOE) to advance the study of scientific phenomena using the Cerebras Wafer-Scale Engine (WSE).