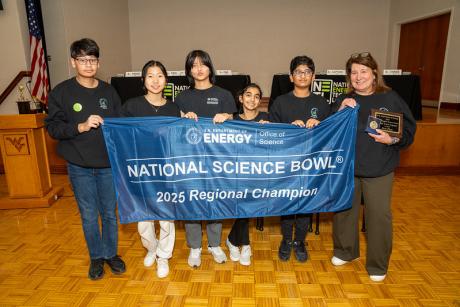

Suncrest Middle School Team 1 captured first place in the 2025 West Virginia Science Bowl (WVSB) middle school competition, which was held Friday, Jan. 31, at the West Virginia University Mountainlair in Morgantown.

WASHINGTON, D.C. — The U.S. Department of Energy’s (DOE) Office of Fossil Energy and Carbon Management (FECM) today announced $13.7 million in federal funding for four projects that will advance large-scale conversion of carbon dioxide (CO2) emissions into environmentally responsible and economically valuable products. With funding provided by the Bipartisan Infrastructure Law, projects will help develop conversion technologies that feasibly produce crucial fuels, building materials, and other carbon-based products from captured carbon emissions.

WASHINGTON, D.C. – The U.S. Department of Energy’s (DOE) Office of Fossil Energy and Carbon Management (FECM) today announced up to $100 million in federal funding for large-scale conversion of carbon emissions captured from industrial operations and power plants into environmentally responsible and economically valuable products. Provided by the Bipartisan Infrastructure Law, the funding will advance the pilot scale testing of carbon conversion technologies with high technology readiness levels (TRLs) capable of achieving significant carbon mitigation via biological, catalytic, or mineralization pathways.

WASHINGTON, D.C. — The U.S. Department of Energy’s (DOE) Office of Fossil Energy and Carbon Management (FECM) today announced $45 million in federal funding for six projects to create regional consortia to accelerate the development of critical mineral and materials supply chains including novel nonfuel carbon-based products from secondary and unconventional feedstocks. Realizing the value of secondary and unconventional feedstocks, such as coal and coal by-products, effluent waters from oil and gas development, and acid mine drainage will enable the United States to rebuild domestic supply chains for critical minerals and materials. By focusing on abundant American secondary and unconventional sources, these investments will support dependable and enduring supplies for American manufacturing and production of technologies essential to clean energy and our nation’s defense.

WASHINGTON, D.C. – The U.S. Department of Energy’s (DOE) Office of Fossil Energy and Carbon Management (FECM) today announced $101 million in federal funding for five projects to support the development of carbon dioxide (CO2) capture, removal, and conversion test centers for cement manufacturing facilities and power plants. Accelerating the responsible development and deployment of technologies to capture CO2 emissions from industrial operations and power generation and to remove CO2 directly from the atmosphere will help reduce CO2 emissions, provide new job opportunities, and strengthen the Nation’s energy security.

Susteon Inc., with project management from NETL, is working to develop and deploy direct air capture (DAC) technologies by conducting fundamental research and bench-scale testing of new materials and processes that could result in integrated systems capable of continuous atmospheric carbon dioxide (CO2) capture and conversion to valuable products.

NETL has updated its previous life cycle analysis (LCA) focused on the U.S. natural gas supply chain, specifically studying the production, gathering and boosting, processing, transmission and storage, and distribution of natural gas to domestic consumers. The new research expands the LCA to include more measurement-based data and incorporates important modeling changes including regionalization of processing, transmission, and distribution stages, which aim to improve the understanding of life cycle impacts associated with natural gas and help inform effective mitigation and business strategies towards a sustainable future.

WASHINGTON, D.C.—The U.S. Department of Energy (DOE) and the U.S. Environmental Protection Agency (EPA) today announced approximately $850 million for 43 projects selected for negotiation that will help small oil and gas operators, Tribes, and other entities across the country to reduce, monitor, measure, and quantify methane emissions from the oil and gas sector as part of President Biden’s Investing in America agenda. The funding builds on unprecedented action across the Biden-Harris Administration to dramatically reduce methane emissions, with agencies taking nearly 100 actions since 2023, including the finalization of an EPA rule that is expected to reduce methane emissions from covered oil and gas sources by 80% from 2024 to 2038 compared to projected emissions without the rule.

WASHINGTON, D.C. — The U.S. Department of Energy’s (DOE) Office of Fossil Energy and Carbon Management (FECM) today announced it is re-opening a funding opportunity to make up to $500 million available for projects that will help expand carbon dioxide (CO2) transportation infrastructure across the United States. Accelerating the development and deployment of carbon management technology to capture CO2 emissions from industrial operations and power generation, as well as directly from the atmosphere, requires a safe and reliable system that can transport the captured CO2, either for permanent geologic storage or for conversion to useful, durable products. These efforts will reduce CO2 emissions, provide new job opportunities, and enhance our Nation’s energy security.

With the recent announcement of Kelly Rose and James Bielenberg as the senior fellows for Computational Science & Engineering and Materials Science & Engineering, respectively, NETL establishes a full cohort of senior fellows, which also includes Nathan Weiland (Energy Conversion Engineering), Alexandra Hakala (Geologic & Environmental Systems), and John Wimer (Systems Analysis & Engineering).