Researchers from the National Energy Technology Laboratory (NETL) have successfully demonstrated a new oil-spill recovery process under simulated Arctic conditions. The work, which is being conducted under a grant awarded to NETL by the U.S. Department of the Interior’s Bureau of Safety and Environment Enforcement, is focused on verifying that this process can have real-world applications for oil recovery in a harsh Arctic environment.

Contrary to that old cooking adage, “a watched pot never boils,” keeping a careful eye on things—in the kitchen or in the laboratory—can be essential to making a useable (or edible!) final product. Take chocolate, for instance, that foundational block of the food pyramid. An important part of creating high-grade chocolate is a step called tempering, or the melting, stirring, and cooling of the liquid chocolate to align the crystals that give it a smooth texture and a glossy shine.

Fuel cell technology is a unique form of energy creation—an efficient, quiet, and clean method of transforming an energy source (such as propane, diesel, or natural gas) into electricity.

Traditional fossil-fuel power generation technology produce energy through combustion—harnessing the energy of a chemical reaction to power the mechanical processes that produce electricity. This is often a noisy process, and produces exhausts and toxic fumes that must be carefully contained.

Secretary of Energy Rick Perry took part in a ribbon-cutting ceremony today to mark the opening of Petra Nova, the world’s largest post-combustion carbon capture project, which was completed on-schedule and on-budget. The large-scale demonstration project, located at the W.A. Parish power plant in Thompsons, Texas, is a joint venture between NRG Energy (NRG) and JX Nippon Oil & Gas Exploration Corporation (JX).

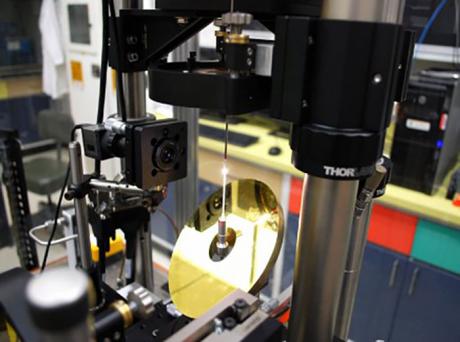

Solid oxide fuel cells (SOFCs), a promising technology that can efficiently produce energy using fossil fuels with no moving parts and low emissions, present a particularly perplexing economic challenge: current systems operate at maximum efficiency between 700 and 1000 degrees Celsius, but such high temperatures shorten their service life, requiring more frequent fuel cell stack replacements. Lowering the operating temperature makes them last longer, but requires additional cells in the stack to deliver the same performance, and that drives up costs.

The U.S. Department of Energy (DOE) announced today that the Illinois Industrial Carbon Capture and Storage (ICCS) project in Decatur, Illinois, has begun operation by injecting carbon dioxide (CO2) into a large saline reservoir. This project received a $141 million investment from DOE, matched by over $66 million in private-sector cost share.

In the 1960s, when humans were taking their first grand leaps into outer space, NASA needed a clean reliable way to supply electricity to its spacecraft. The answer to the problem was fuel cell technology. NASA’s manned space flights marked the first commercial use of the fuel cell, and they have been providing electrical power for space missions—and more down-to-earth applications—for more than 40 years.

In a project managed by the National Energy Technology Laboratory (NETL), GE Global Research has advanced a method to lower the energy requirement and cut the cost of recovering usable water from high-salinity brines. The new technology offers a way to turn a potential waste product into a usable source of water and minerals.

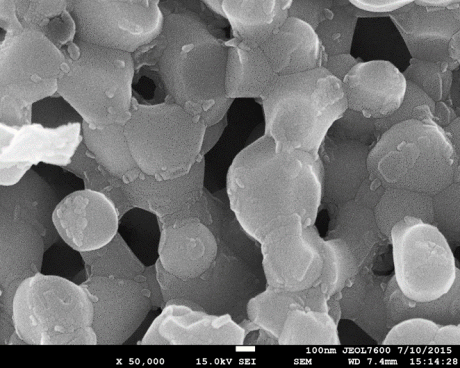

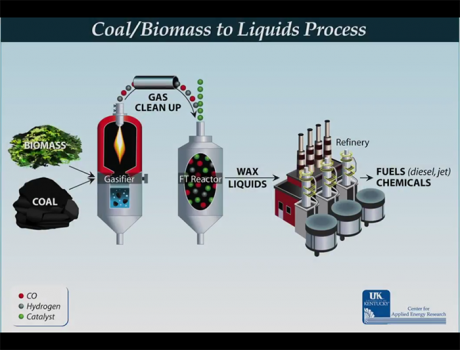

With an eye toward the development of cleaner coal-derived liquid fuels that can someday power cars, trucks, tanks, and even jets, the National Energy Technology Laboratory (NETL) has been supporting researchers at the University of Kentucky as they close in on an innovation that could someday advance the state of the art for transportation fuels production.

Just as the newest jet aircraft technologies require cutting edge innovations like carbon-fiber composites, polymers, and avionics to make them fly, the next generation of high efficiency and environmentally sound energy-producing technologies demand a very specific set of functional materials to make them capable of answering the nation’s increasing energy needs.