- x

- Loudon EOR I: Single-Well Test

- Mumford Hills EOR IIL Liquid CO2

- Sugar Creek EOR III: Immiscible Test

- Tanquary Coal Test

Carbon Storage Atlas

- Why this Location

- Main Research Q&As Discovered

- Lessons Learned

- Field Site Story of Interest

- Geologic Details

- Links to EDX

- Sites

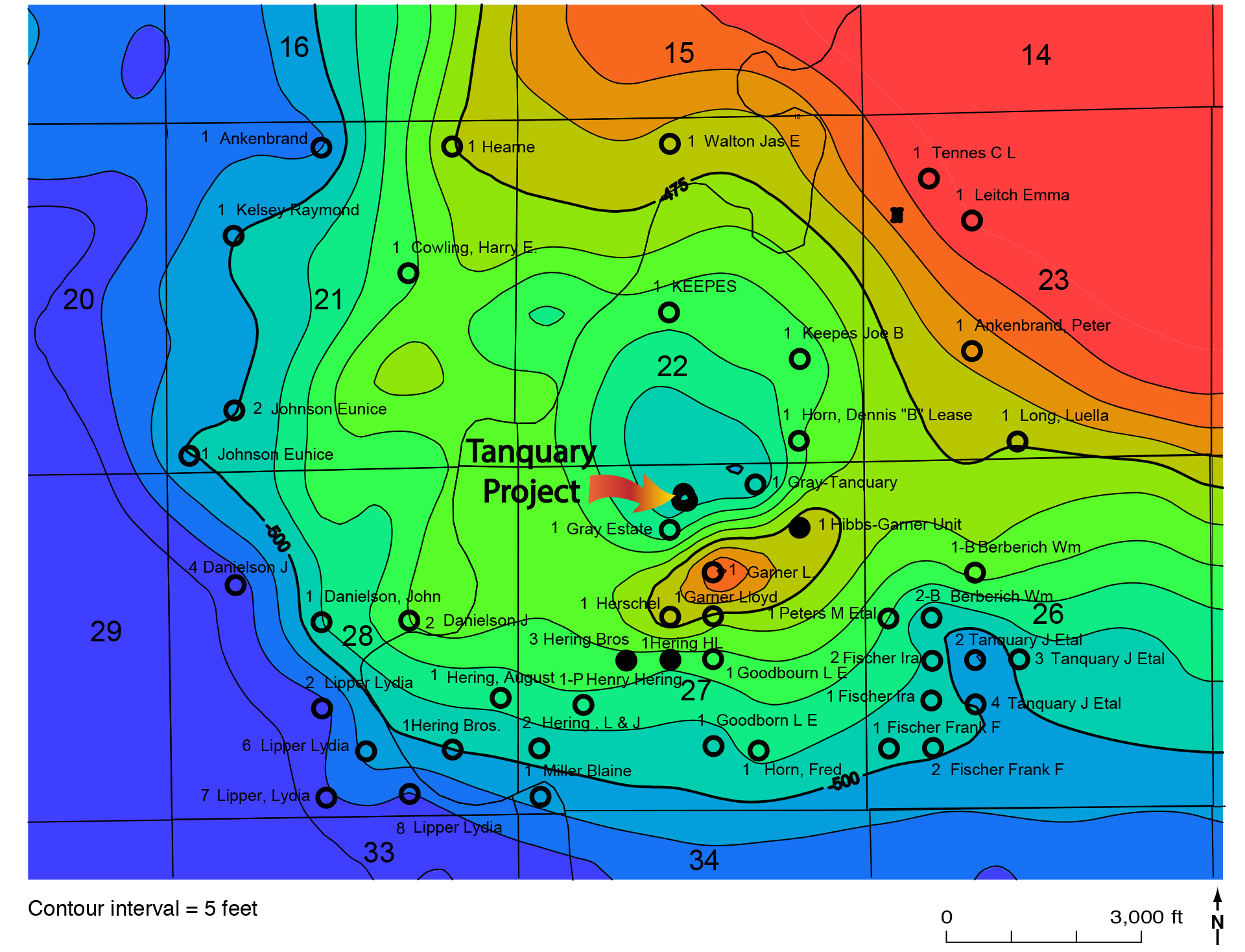

Why this Location

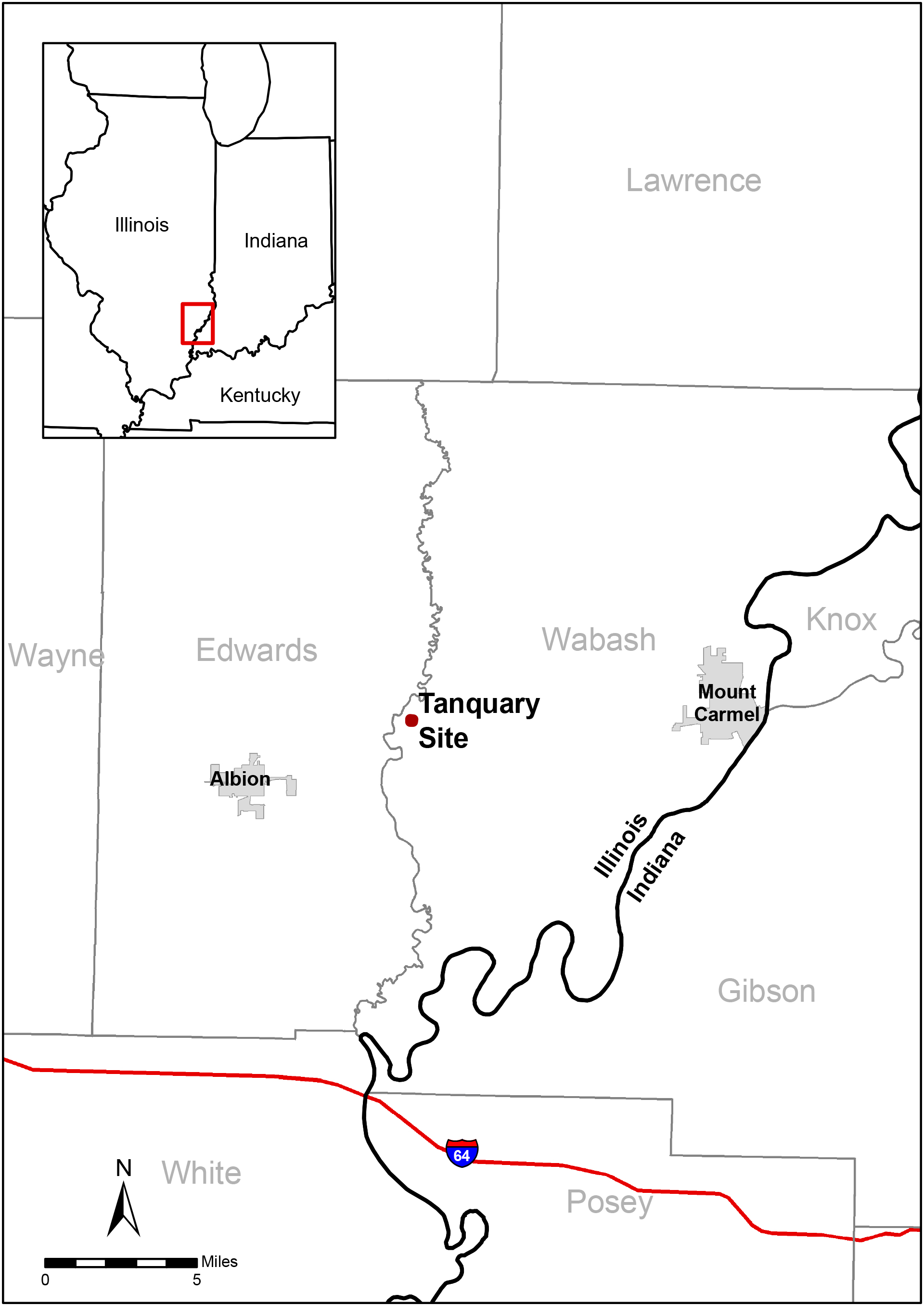

This site was chosen near Browns, Illinois, in western Wabash County in the southeastern part of the state, and is called Tanquary based on the local farm name. The location was chosen because several potential coal seams were identified in nearby oil well logs. Well records existed for all plugged and cased wells within a 0.8-km (0.5-mi) radius. These records indicated that there was overlying groundwater protection provided by casing or plugging cement over the entire aquifer interval, which meant that the site met Illinois regulatory requirements for injection wells in oil and gas fields. The site had adequate size for the pilot operations, good road accessibility, and no surface considerations nearby (e.g., residences). Finally, the owners of the coal rights were agreeable to granting a lease for access, drilling, and carbon dioxide (CO2) injection and monitoring for the duration of the project.

Main Research Q&As Discovered

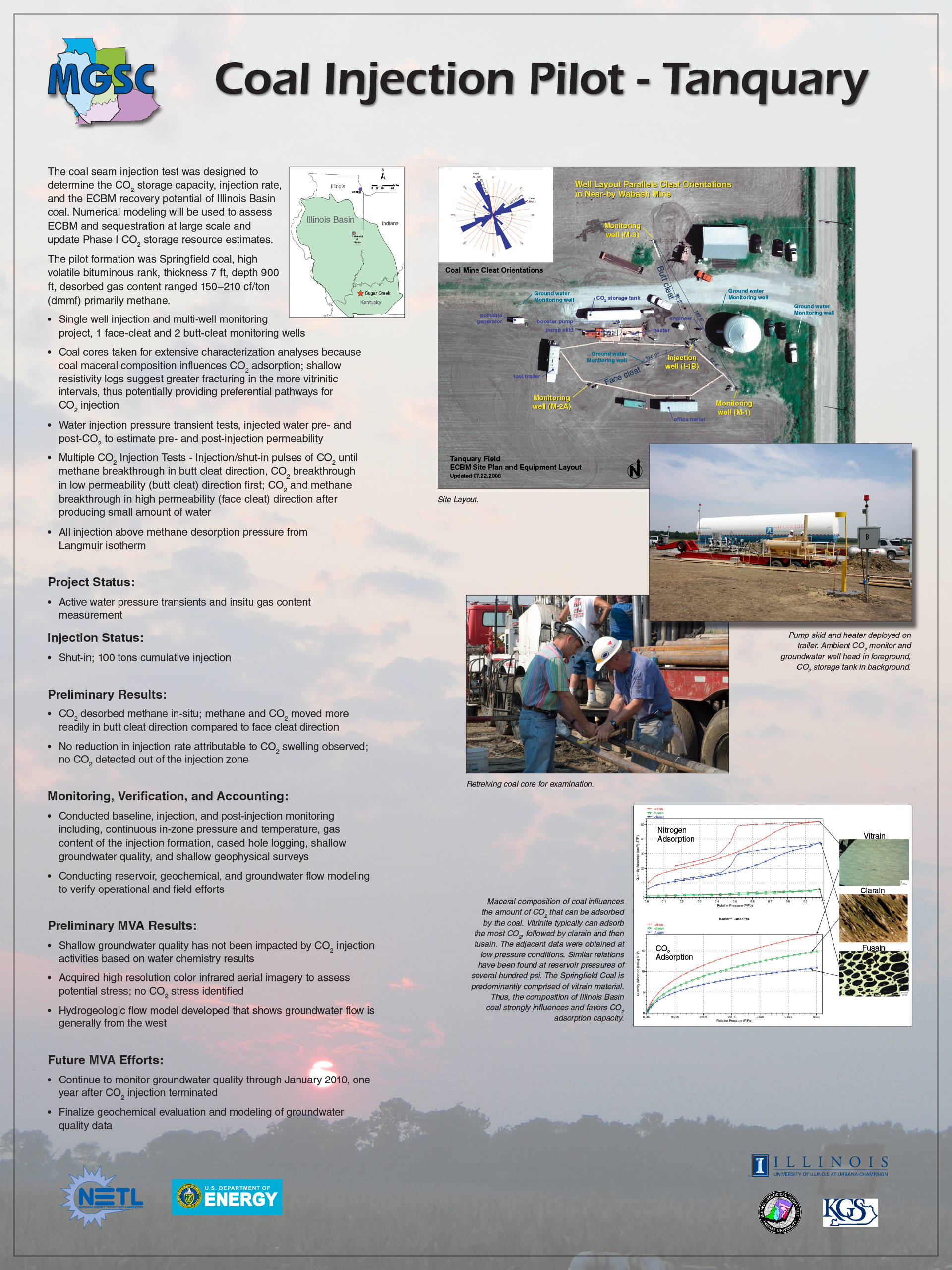

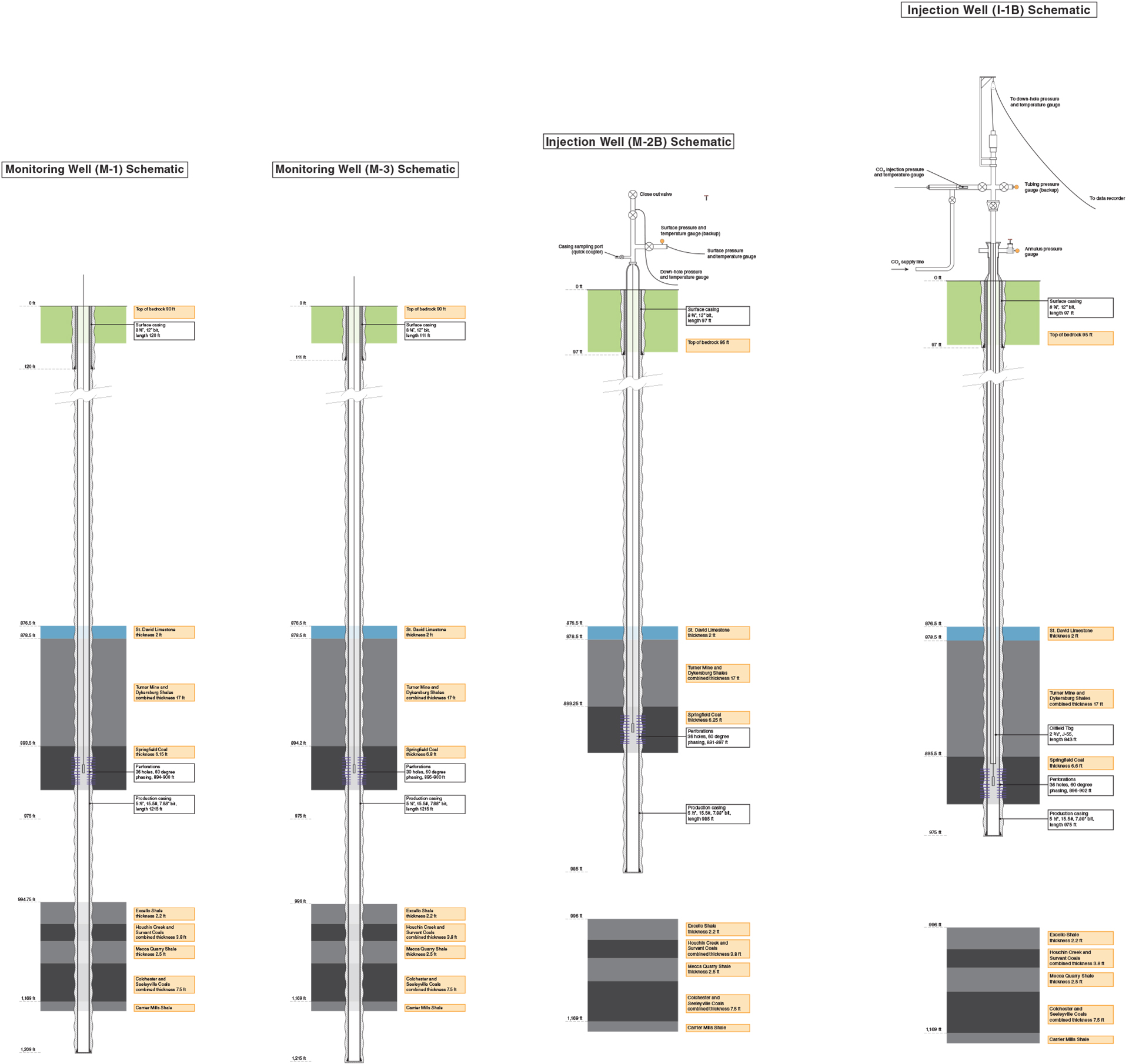

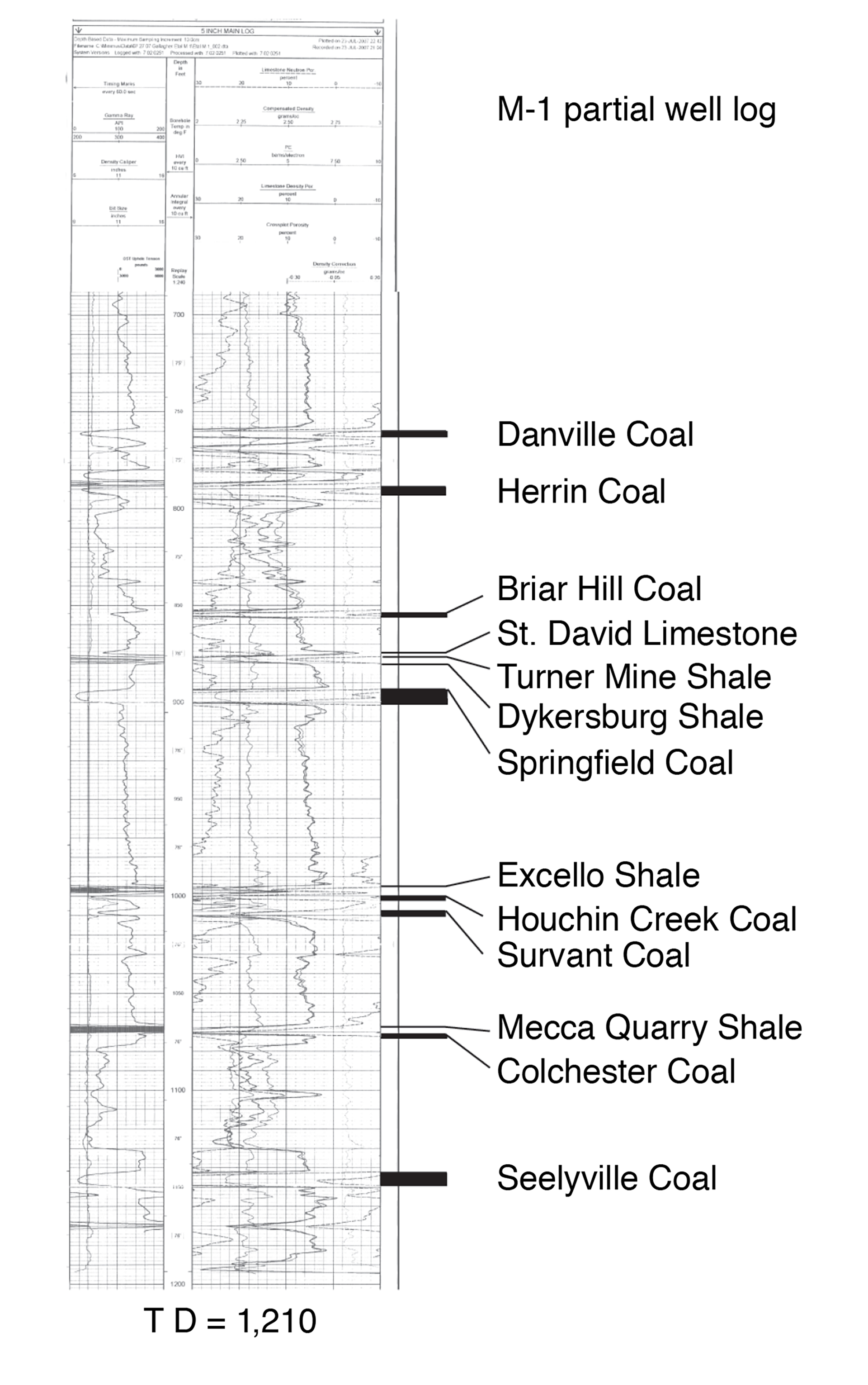

The coal seam injection test was designed to determine the carbon dioxide (CO2) storage capacity, injection rate, and the enhanced coalbed methane (ECBM) recovery potential of Illinois Basin coal. The project involved drilling four new wells into the Springfield coal seam at a depth of ~274 meters (900 feet). The four-well design—an injection well and three monitoring wells—was developed and implemented, based on numerical modeling and permeability estimates from literature and field data. Coal cores were taken during the drilling process and were characterized in detail in the lab.

Injection of CO2 gas took place from June 25, 2008, to January 13, 2009, but injection was suspended several times during this period due to equipment failures and other interruptions. Injection equipment and procedures were adjusted in response to these problems. Pressure responses during injection occurred most quickly and intensely at the face cleat well, M-2. However, methane was detected at the butt cleat wells (M-1 and M-3) within hours of CO2 injection startup, but did not occur at the face cleat well for approximately four months. Carbon dioxide breakthrough first occurred at M-1 (the butt cleat well nearest the injector) approximately one month after injection started, followed by M-3 (the distal butt cleat well) at approximately 120 days. Approximately 92.3 metric tons of CO2 were injected over the duration of the project, at an average rate of 0.93 metric tons per day.

A monitoring, verification, and accounting (MVA) program was set up to detect CO2 leakage. Atmospheric CO2 levels were monitored, as were indirect indicators of CO2 leakage such as plant stress, changes in gas composition at wellheads, and changes in several shallow groundwater characteristics (e.g., alkalinity, pH, oxygen content, dissolved solids, mineral saturation indices, and isotopic distribution). Results showed that there was no CO2 leakage into groundwater or CO2 escape at the surface. Post-injection cased hole well log analyses supported this conclusion.

Numerical and analytical modeling achieved a relatively good match with observed field data. Based on the model results, the plume was estimated to extend 152 meters (500 feet) in the face cleat direction and 54.9 meters (180 feet) in the butt cleat direction. Using the calibrated model, additional injection scenarios—injection and production with an inverted five-spot pattern and a line drive pattern—could yield methane recovery of up to 70% of the original gas in place.

Lessons Learned

Approximately 100 metric tons of carbon dioxide (CO2) were injected over a 100-day period, averaging 0.46 metric ton of coal/meters/day (0.15 ton/feet/day) at this site.

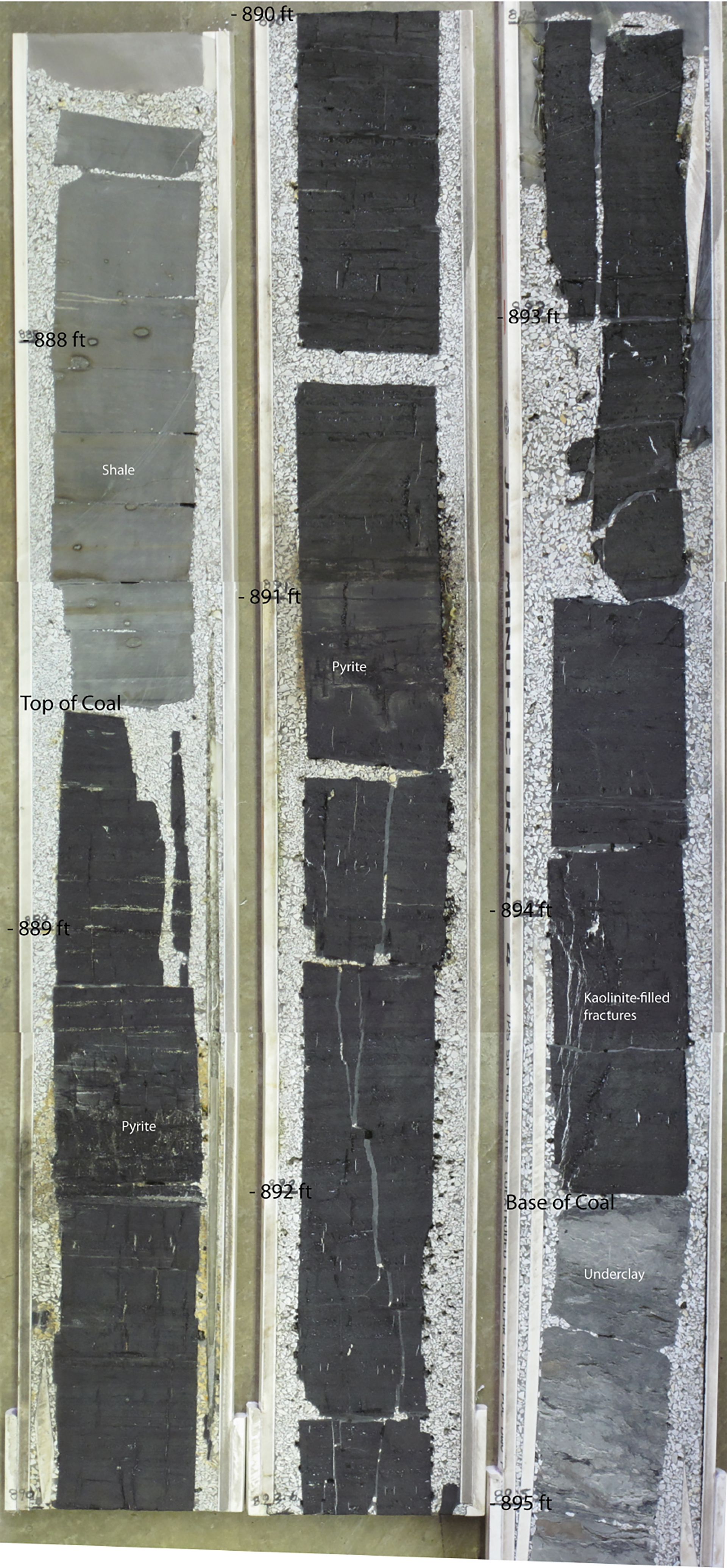

Coal characterization showed that the coals at the Tanquary site had some of the highest gas content measured in the Basin. The pre-CO2 water injection tests confirmed the face and butt cleat direction that was measured in a nearby underground mine. The micro-size pore system contributed significantly to the total porosity.

Through pressure transient analyses, increasing permeability was estimated followed by a series of steadily decreasing trends. If injection had been for a longer period, permeability may have increased due to continued increase in pressure of the cleat system and subsequent opening of the cleats. The cased hole well log analyses, chemical and isotopic compositional data from the shallow groundwater samples, groundwater geochemical modeling, and color-infrared (CIR) imagery were used to conclude that injected CO2 remained in the coal seam.

Story of Interest

In the application of color-infrared (CIR) photography for monitoring leaks of injected carbon dioxide (CO2) at and near the injection site, the farmland vegetation serves as a surrogate indicator of the stressor. Monitoring technologies deployed at the Tanquary site indicate that leakage of CO2 from the coal seam injection zone did not occur; however, the CIR photography provided the basis for interesting observations unrelated to the pilot project. In the CIR digital aerial orthophotograph taken June 27, 2009, the site is shown as it appeared in early summer surrounded by healthy corn fields. The distinctive bands in the corn are due to the differing cell structures of two separate corn hybrids planted in alternating rows. Although the corn leaves appear to be the same green color to the naked eye (i.e., in the visible portion of the electromagnetic spectrum), the near-infrared reflected energy passes into the cell structure of the leaves and is re-reflected back to the digital mapping camera sensor in direct relationship to the nature and character of the differing cell structure. This image is a good demonstration of the sensitivity of CIR imagery and the value of plants as an excellent surrogate for monitoring stress.

Geologic Details

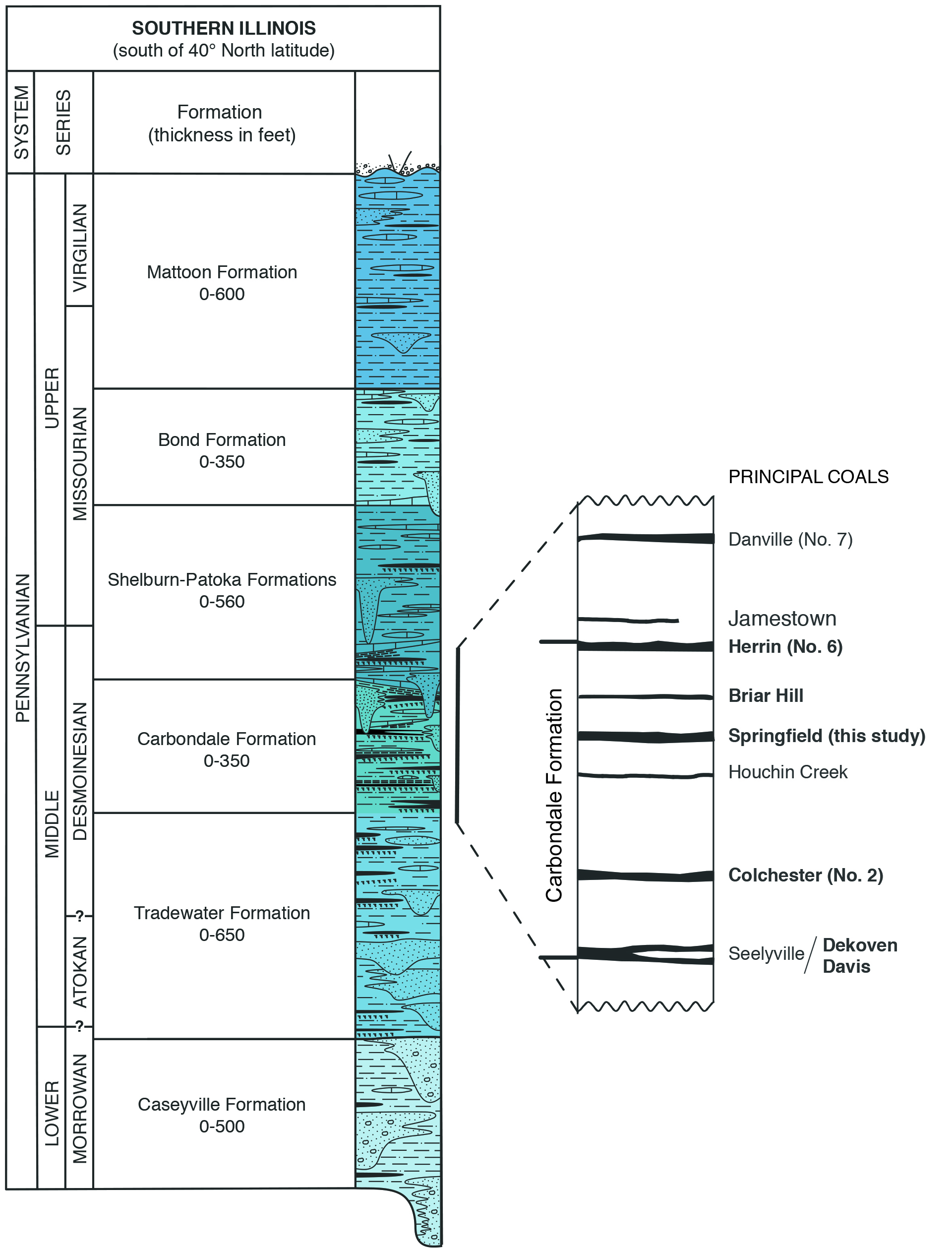

The carbon dioxide (CO2) enhanced coalbed methane (ECBM) pilot project completed a coal seam injection study at the Tanquary site in Wabash County, Illinois, designed to determine the CO2 storage capacity, injection rate, and the ECBM recovery potential of Illinois Basin coal. The Middle Pennsylvanian (Desmoinesian Series) coals of the Carbondale Formation were the target for CO2 assessment with the Herrin, Springfield, and Seelyville coal seams considered as the main targets prior to drilling any of the pilot wells. The Springfield Coal Member, a high-volatile bituminous rank coal occurring at a depth of approximately 274 meters (900 feet) with a thickness of approximately 2.1 meters (7 feet), was selected for injection trials. Coal cores were taken for extensive characterization analyses because coal characteristics vary across the basin and also laterally between wells at the site and vertically within a given seam. Thus, it is critical to characterize injection site coals to best predict the potential for CO2 injection and storage capacity. Coal maceral composition averaged 76.5% vitrinite. Coal maceral composition influences CO2 adsorption; shallow resistivity logs suggest greater fracturing in the more vitrinitic intervals, thus potentially providing preferential pathways for CO2 injection.

Links to EDX

Midwest Geological Sequestration Consortium, Phase II, Sequestration and Enhanced Coal Bed Methane Pilot Project, Tanquary Farms Test Site, Wabash County, Illinois

Sequestration and Enhanced Coal Bed Methane: Tanquary Farms Test Site, Wabash County, Illinois: Final Report

The Midwest Geological Sequestration Consortium (MGSC) carried out a pilot project to test storage of carbon dioxide (CO2) in the Springfield Coal Member of the Carbondale Formation (Pennsylvanian System), in order to gauge the potential for large-scale CO2 sequestration and/or enhanced coal bed methane recovery from Illinois Basin coal beds.