- x

- Loudon EOR I: Single-Well Test

- Mumford Hills EOR IIL Liquid CO2

- Sugar Creek EOR III: Immiscible Test

- Tanquary Coal Test

Carbon Storage Atlas

- Why this Location

- Main Research Q&As Discovered

- Lessons Learned

- Field Site Story of Interest

- Geologic Details

- Links to EDX

- Sites

Why this Location

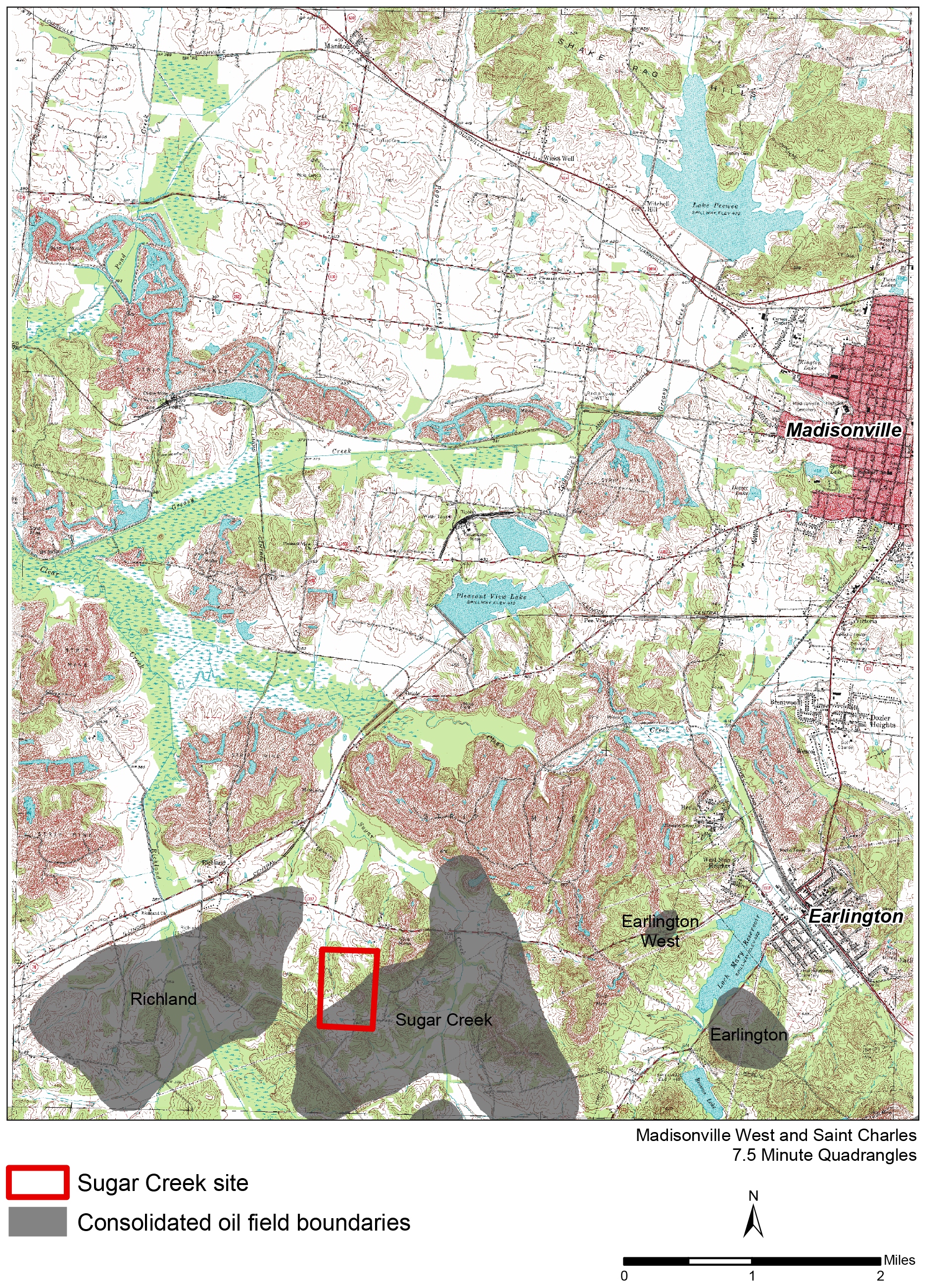

This enhanced oil recovery (EOR) III pilot site was screened to have current reservoir pressure and temperature sufficient to sustain an immiscible flood, but not at depleted pressure. After applying the rigorous EOR site-screening criteria, the Sugar Creek oil field in Hopkins County, Kentucky, was chosen. The Sugar Creek oil field was owned and operated by Gallagher Drilling, Inc. (GDI), based in Evansville, Indiana.

Although several wells in the waterflooded field were temporarily or permanently abandoned, the oil field had some relatively new wells and no reports of major casing leaks or other production well problems. The site’s tank battery had excellent year-round road access, and continuous carbon dioxide (CO2) delivery was expected to be possible. Analyses and interpretations of projections from a simplistic but representative geologic model of the Sugar Creek oil field suggested that the CO2 injection rates and cumulative injection volume for the pilot design could be achieved in the timeframe and budget allotted

Main Research Q&As Discovered

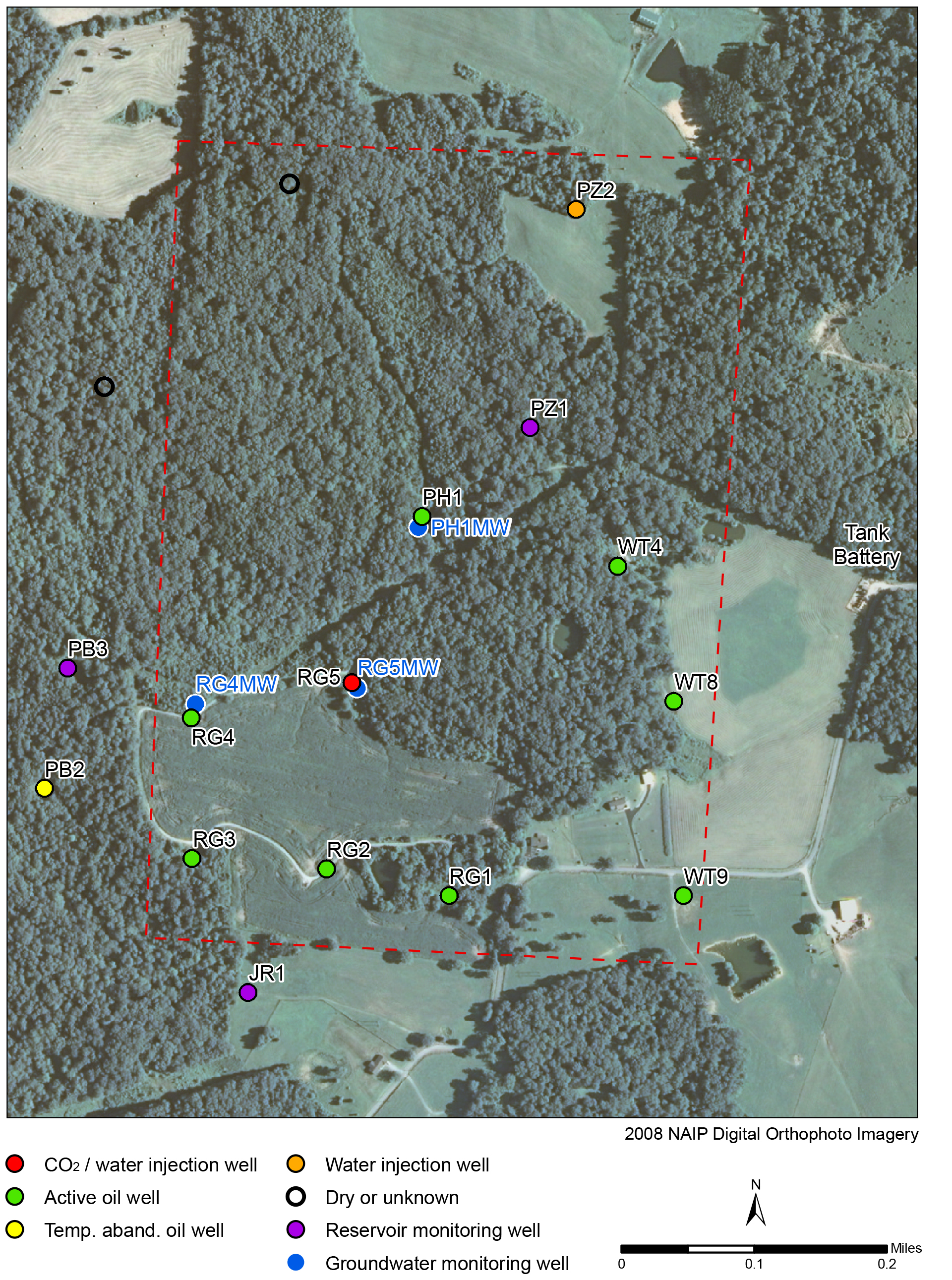

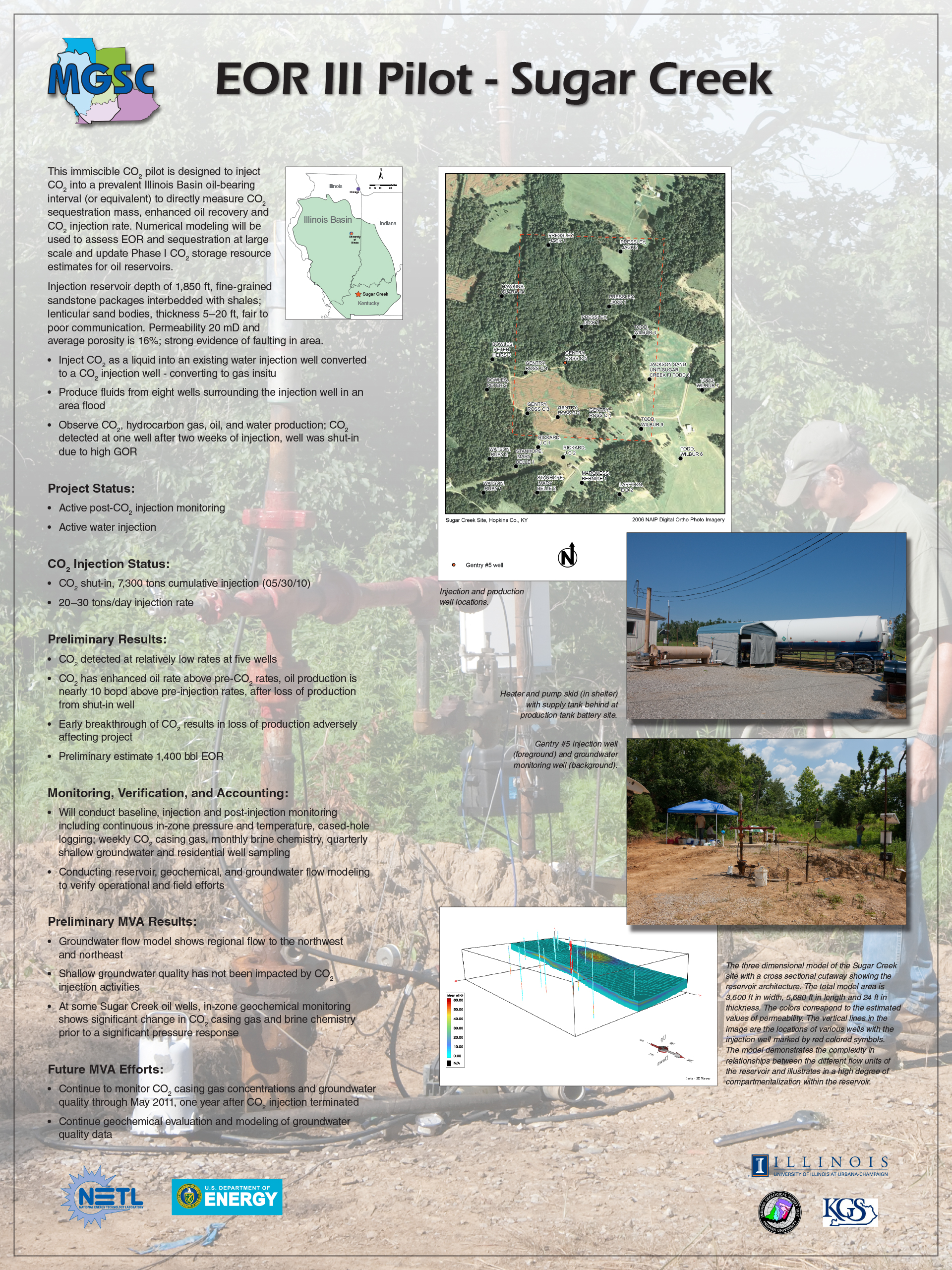

This immiscible carbon dioxide (CO2) pilot was designed to inject liquid CO2 into an oil-bearing Mississippian sandstone to directly measure CO2 storage mass, enhanced oil recovery (EOR) and CO2 injection rate, and to gauge the large-scale CO2 storage that might be realized from EOR in mature Illinois Basin oil fields via immiscible liquid CO2 flooding.

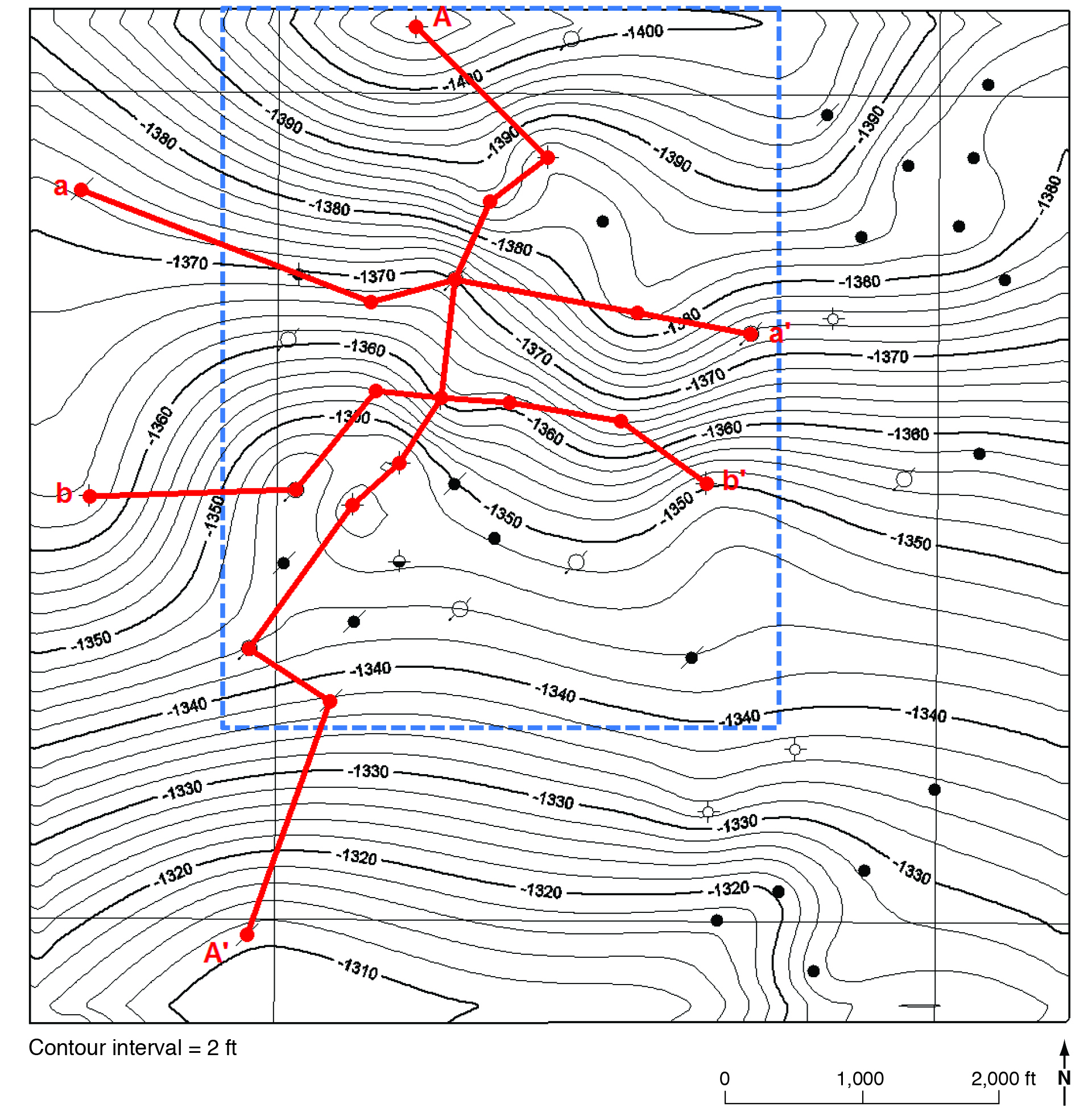

A water injection well surrounded by four nearby producing wells was converted to CO2 injection, and several additional production and observation wells were instrumented to collect temperature and pressure response information. The CO2 injection period lasted from May 13, 2009, through May 26, 2010, and a total of 6,560 metric tons of CO2 were injected into the reservoir at rates that generally ranged from 18.2 to 27.3 metric tons per day. The CO2 injection was followed by more than a year of water injection and continued monitoring. Pressure changes and elevated CO2 levels in response to injection (breakthrough) occurred at five production wells during the one-year injection period, all within the first five months.

An estimated 16% of the injected CO2 was produced at the surface from wells and the gas separator. Consequently, 84% of the injected CO2 was stored at the Sugar Creek oil field after one year of post-CO2 injection monitoring. Project improved oil recovery (IOR) was estimated at 1,574 m3 (9,900 barrels [bbl]) and CO2 EOR at 429 to 509 m3 (2,700 to 3,200 bbl). These figures would have been higher if not for variations in oil production rate due to operational problems. Oil production rates did not return to pre-shut-in level after lengthy winter injection hiatuses, but they remained elevated relative to production rates immediately before the pilot.

Extensive monitoring, verification, and accounting (MVA) sampling and analysis of brine, groundwater, and wellhead gas was carried out, and groundwater and kinetic modeling and mineralogical analysis were also employed. No CO2 leakage into groundwater was detected and cased-hole logging at several wells did not detect any CO2 in the near-wellbore region.

A reservoir simulation model calibrated to field data was used to assess the full-field EOR potential at the Sugar Creek oil field, and projections indicated that full-field CO2 injection for 20 years could have 5.5% incremental oil recovery, or 27,700 m3 (174,000 bbl), with a CO2 net utilization of 160 m3/m3 (880 ft3/bbl). The potential CO2 storage is estimated to be 5,200 to 9,500 metric tons. At lower reservoir pressure, less CO2 can be stored.

Lessons Learned

The Scurry Area Canyon Reef Operator’s Committee (SACROC) Unit pilot was an example of a medium-scale validation test in a sink that may have capacity for possible larger-scale storage operations in the future. These validation tests also demonstrate multiple value-added benefits for enhanced oil recovery (EOR) and storage. The SACROC Unit study during Phase II provided valuable experience for going forwards into the Southwest Regional Partnership on Carbon Sequestration’s (SWP) Phase III project, which is a large scale carbon dioxide (CO2)-EOR project located in the Farnsworth Unit in northern Texas. Efficacy of CO2 trapping mechanisms in CO2-EOR, site characterization, and monitoring, verification, and accounting (MVA) protocols, all of which learned from the SACROC Unit project, played critical roles in designing the SWP Phase III project. The approach of dividing research into working groups such as characterization, simulation, MVA, and risk-assessment was initiated in the SACROC Unit project. In addition, the SWP team strengthened its non-technical capabilities through clear communication with operators and effective outreach in the SACROC Unit project, which was also important in the SWP Phase III project.

Story of Interest

In July 2009, a leak in the pipe supplying pressurized carbon dioxide (CO2) to an injection well was observed at the Sugar Creek enhanced oil recovery (EOR) site. Carbon dioxide was escaping from the supply pipe located approximately 1 meter (~3.3 feet) underground. The leak was discovered visually by site personnel and injection was halted immediately. At its largest extent, the hole created by the leak was approximately 1.9 meter (~6.2 feet) long by 1.7 meter (~5.6 feet) wide and 0.7 meter (~2.3 feet) deep in the land surface. This circumstance provided an excellent opportunity to evaluate the performance of several monitoring techniques, including soil CO2 flux measurements, portable infrared gas analysis, thermal infrared imagery, and aerial hyperspectral imagery.

Valuable experience was gained during this effort. Lessons learned included determining: (1) hyperspectral imagery was not effective in detecting this relatively small, short-term CO2 leak; (2) even though injection was halted, the leak remained dynamic and presented a safety risk concern during monitoring activities and; (3) the atmospheric and soil monitoring techniques used were relatively cost-effective, easily and rapidly deployable, and required minimal manpower to setup and maintain for short-term assessments. However, because of the limitations of the equipment and the very dynamic nature of the leak, trying to detect and quantify unknown CO2 leaks with these monitoring methods was challenging, even at this small scale, and could be more difficult at larger scales.

Geologic Details

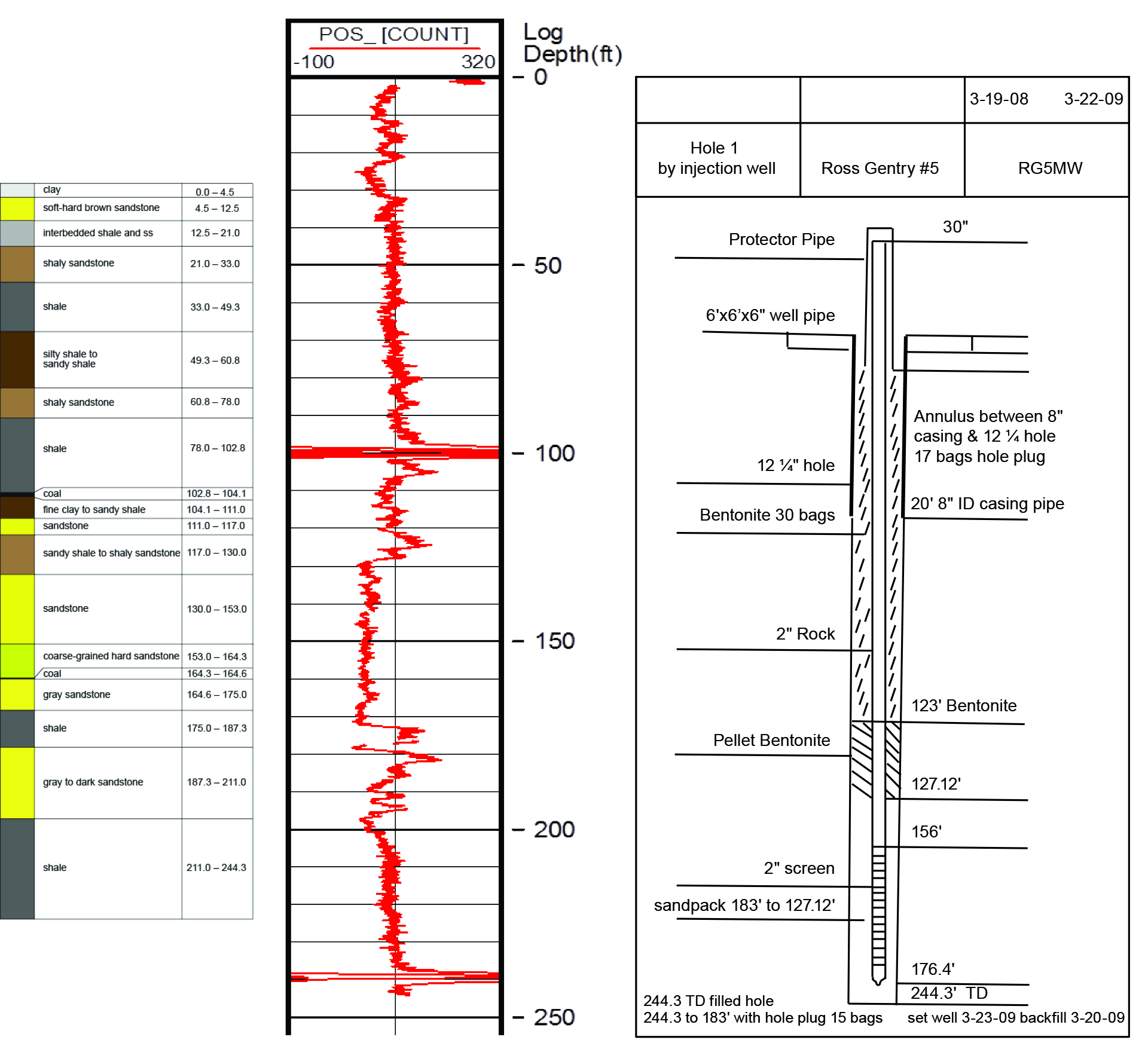

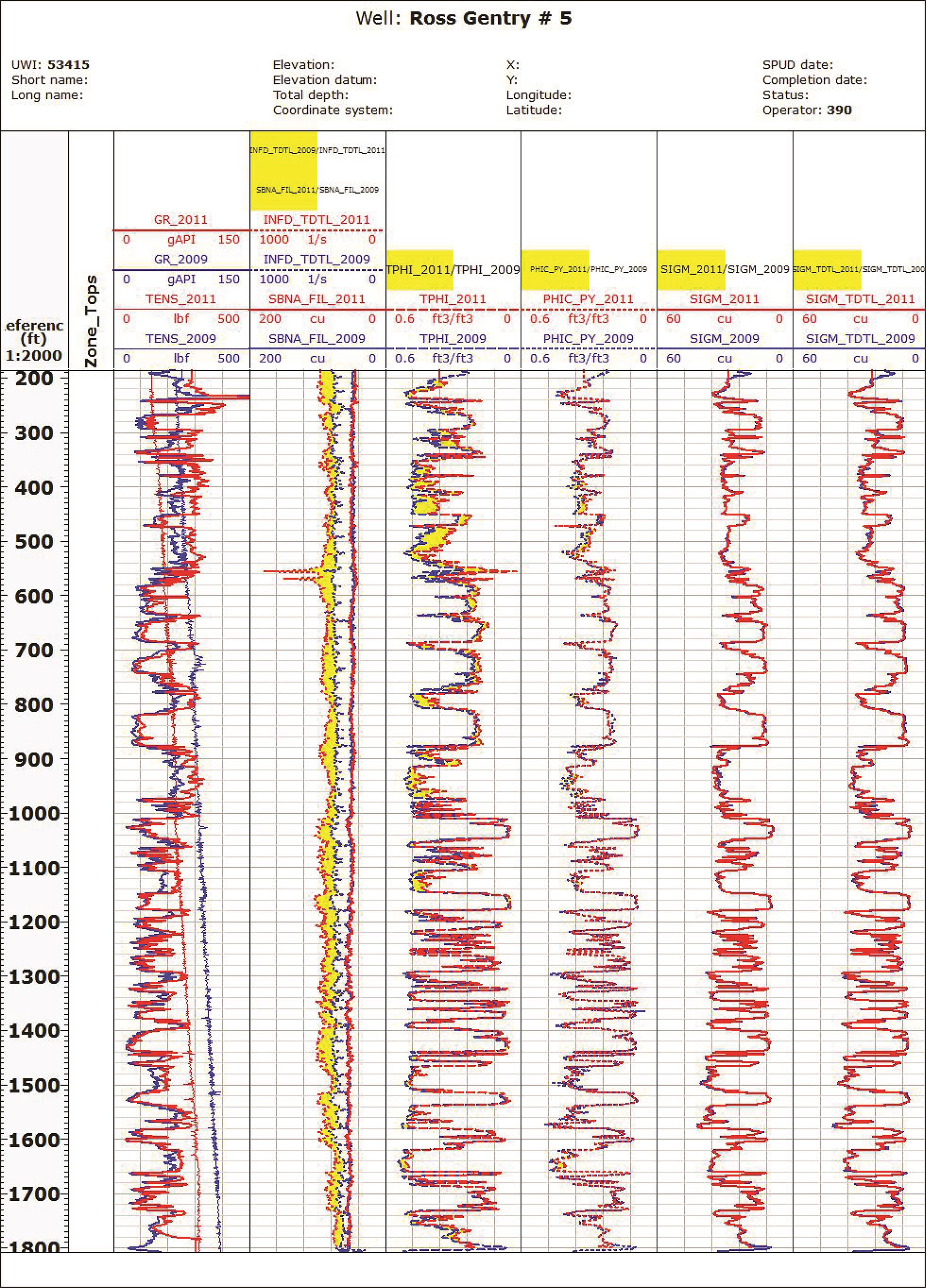

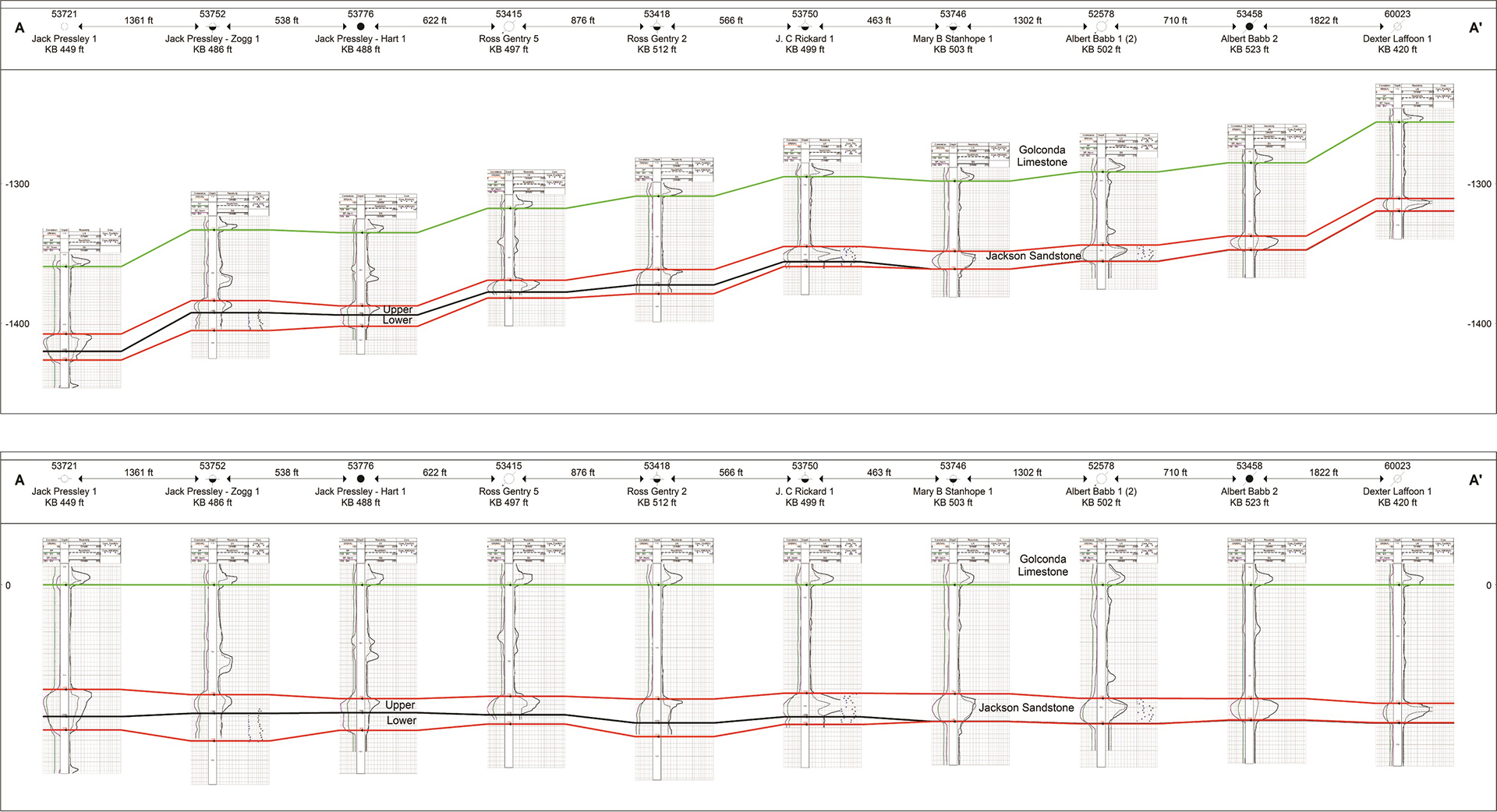

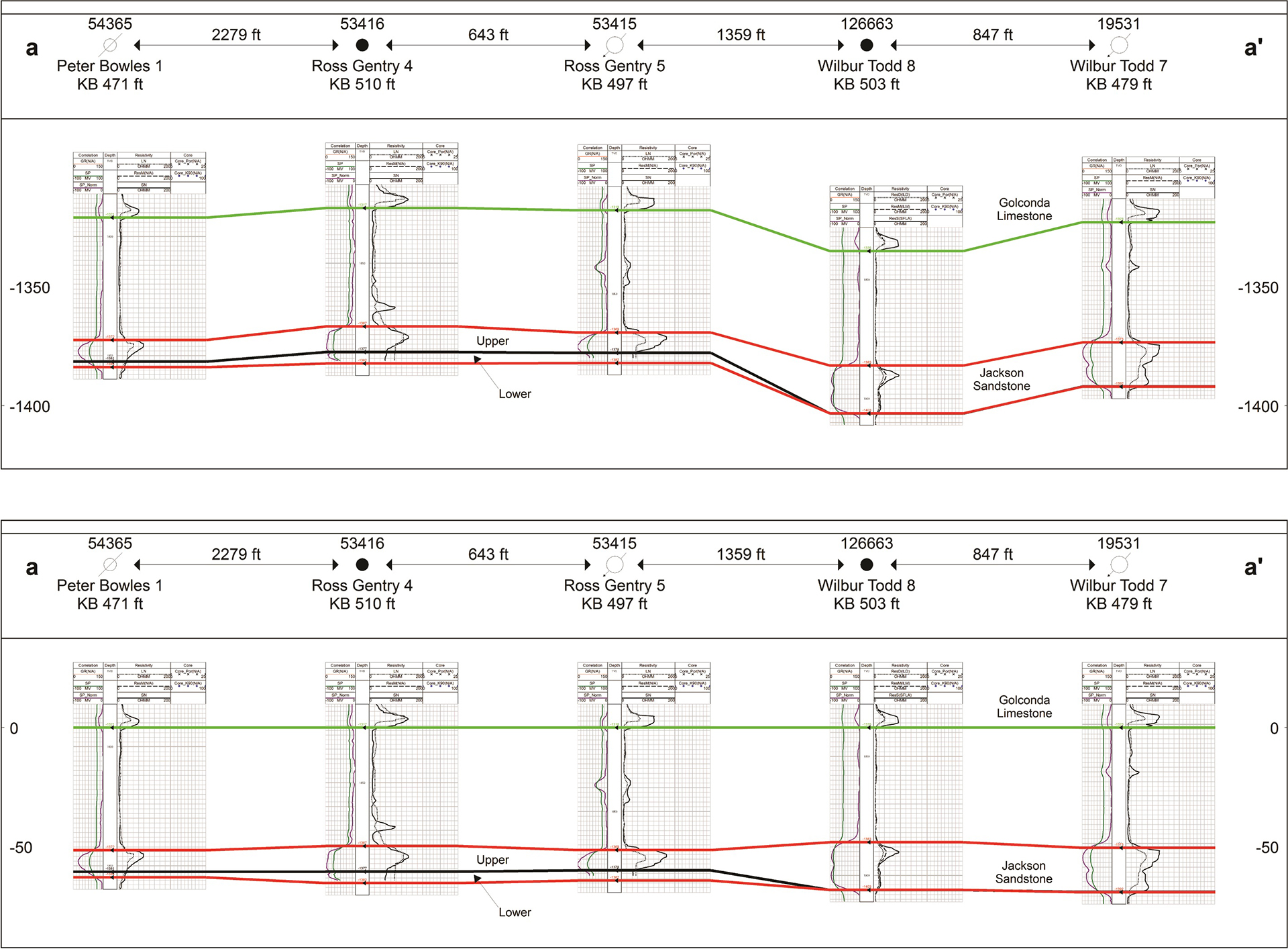

The immiscible carbon dioxide (CO2) enhanced oil recovery (EOR) III pilot study injected into the Mississippian Jackson sandstone in the Sugar Creek oil field, Hopkins County, Kentucky. In Sugar Creek, the Jackson sandstone is approximately 564 meters (1,850 feet) deep, consisting of fine-grained lenticular sandstone bodies, 1.5 to 6 meters (5 to 20 feet) in thickness, interbedded with shale. The Jackson sandstone, which lies stratigraphically above the Cypress sandstone, closely resembles it in lithology and depositional environment. Through geophysical log cross section interpretation, the Jackson sandstone can be separated into an upper and lower interval that may tend to coalesce into a single interval on the eastern mapped area. Additionally, an interval of calcareous cemented sandstone (approximately 0.3 meters [~1 foot thick]) has been observed in core sample and logs in the upper Jackson sandstone. Both factors have resulted in fair to poor reservoir communication. The widespread distribution of the Jackson sandstone encapsulated in thick marine shales; the geometry and orientation of the reservoir; and the presence of sporadic, thin beds of carbonate-cemented sandstone indicate that the sandstone was deposited in a near-shore marine environment. Although whole core samples were not available for the reservoir in this field, core analysis reports provided information about average porosity (16%) and permeability (20 millidarcies [mD]).

Links to EDX

Midwest Geological Sequestration Consortium, Phase II, Enhanced Oil Recovery Pilot Project, Sugar Creek Oil Field, Hopkins County, Kentucky

CO2 Storage and Enhanced Oil Recovery: Sugar Creek Oil Field Test Site, Hopkins County, Kentucky: Final Report

The Midwest Geological Sequestration Consortium (MGSC) carried out a small-scale carbon dioxide (CO2) injection test in the Jackson sandstone (Mississippian System Big Clifty Sandstone Member) in order to gauge the large-scale CO2 storage that might be realized from enhanced oil recovery (EOR) of mature Illinois Basin oil fields via immiscible liquid CO2 flooding.