- x

- Loudon EOR I: Single-Well Test

- Mumford Hills EOR IIL Liquid CO2

- Sugar Creek EOR III: Immiscible Test

- Tanquary Coal Test

Carbon Storage Atlas

- Why this Location

- Main Research Q&As Discovered

- Lessons Learned

- Field Site Story of Interest

- Geologic Details

- Links to EDX

- Sites

Why this Location

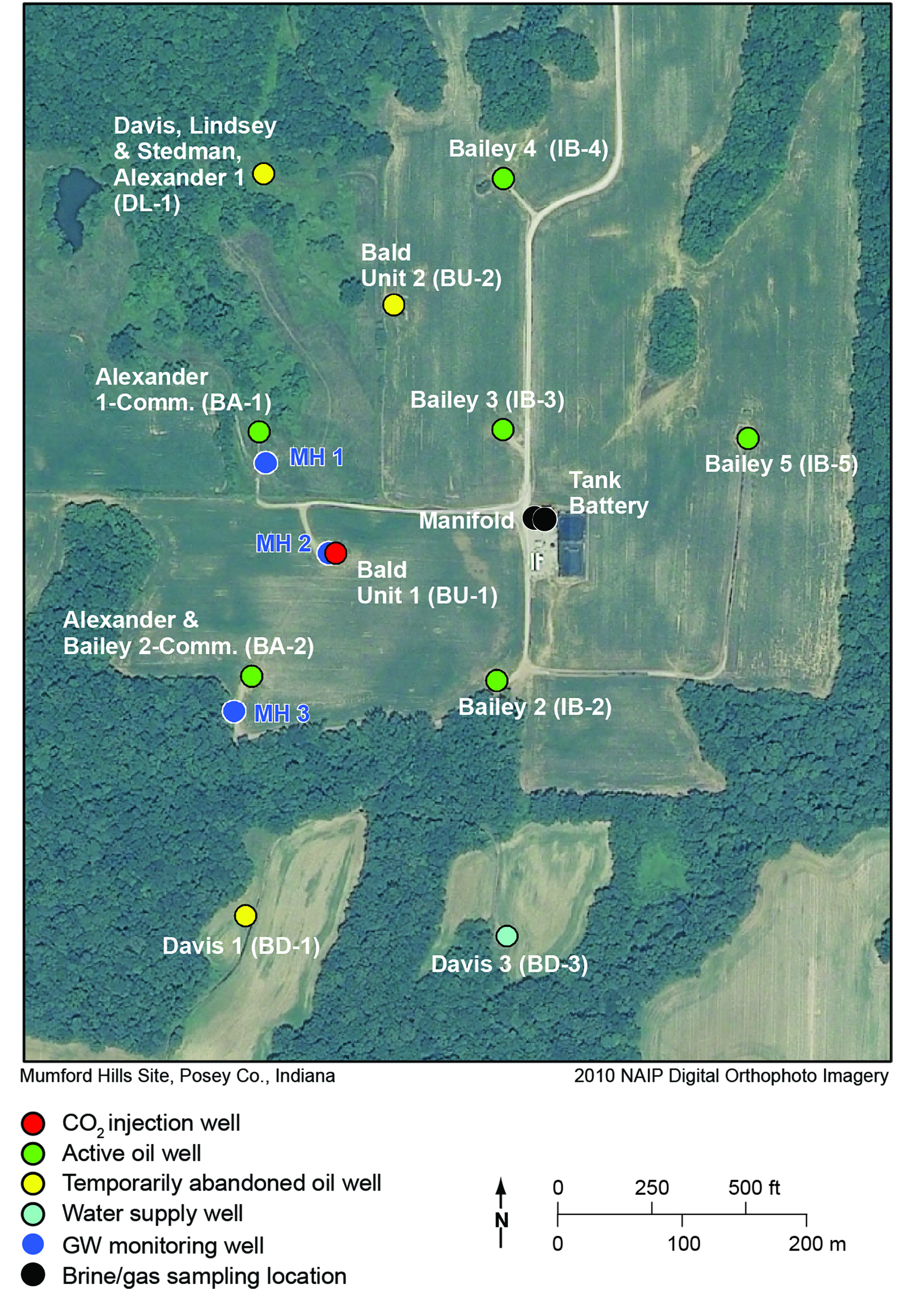

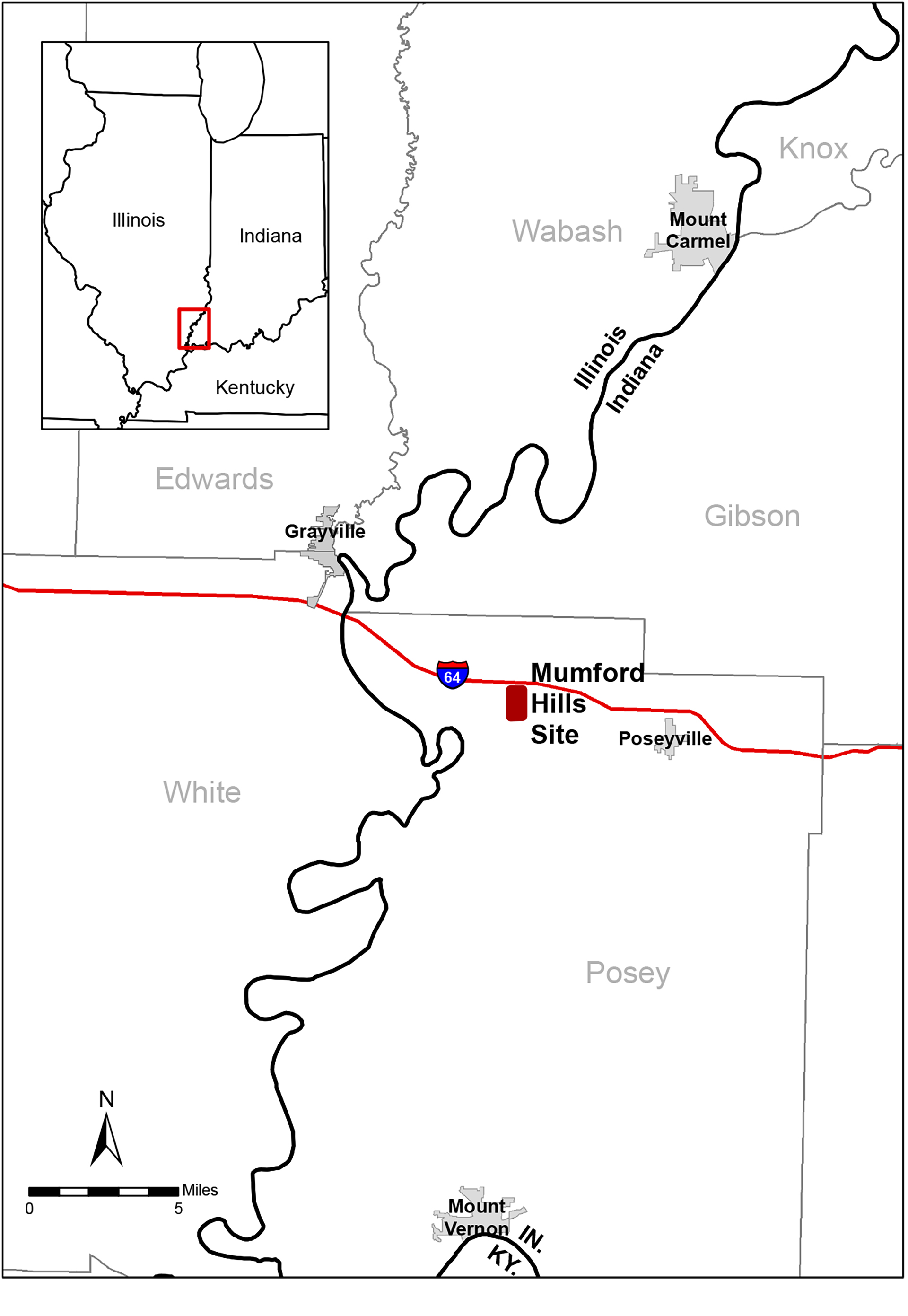

The Bald Unit in the Mumford Hills oil field in Posey County, southwestern Indiana, was selected as the site for the Midwest Geological Sequestration Consortium (MGSC) enhanced oil recovery (EOR) II pilot study. The site determination was based on screening of five criteria: (1) conditions in the reservoir conducive to a miscible liquid carbon dioxide (CO2) flood; (2) operation and development history of the field; (3) surface conditions to allow delivery of CO2 via tanker trucks; (4) wellbore condition of producing and injection wells; and (5) results of preliminary geologic and reservoir modeling.

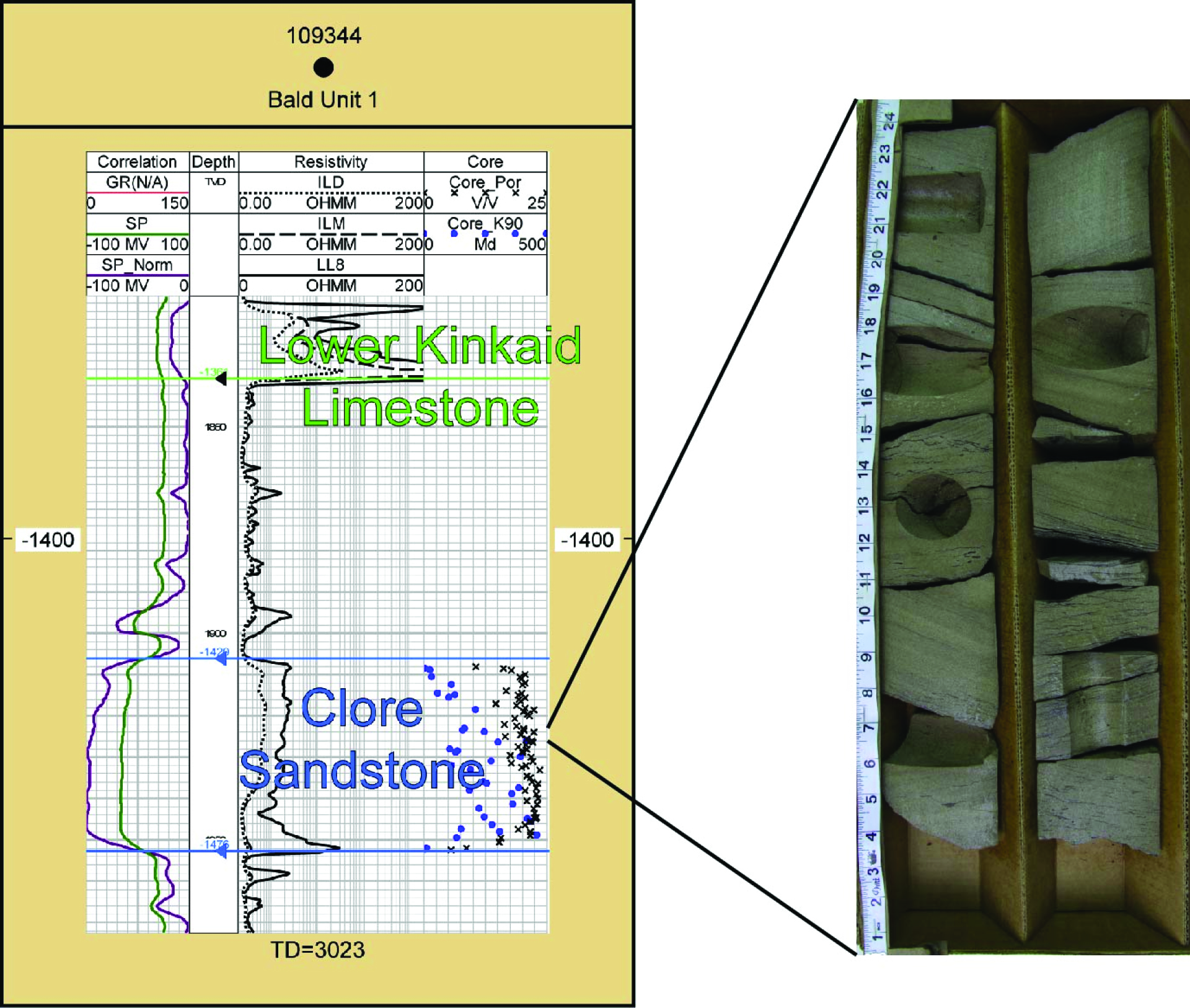

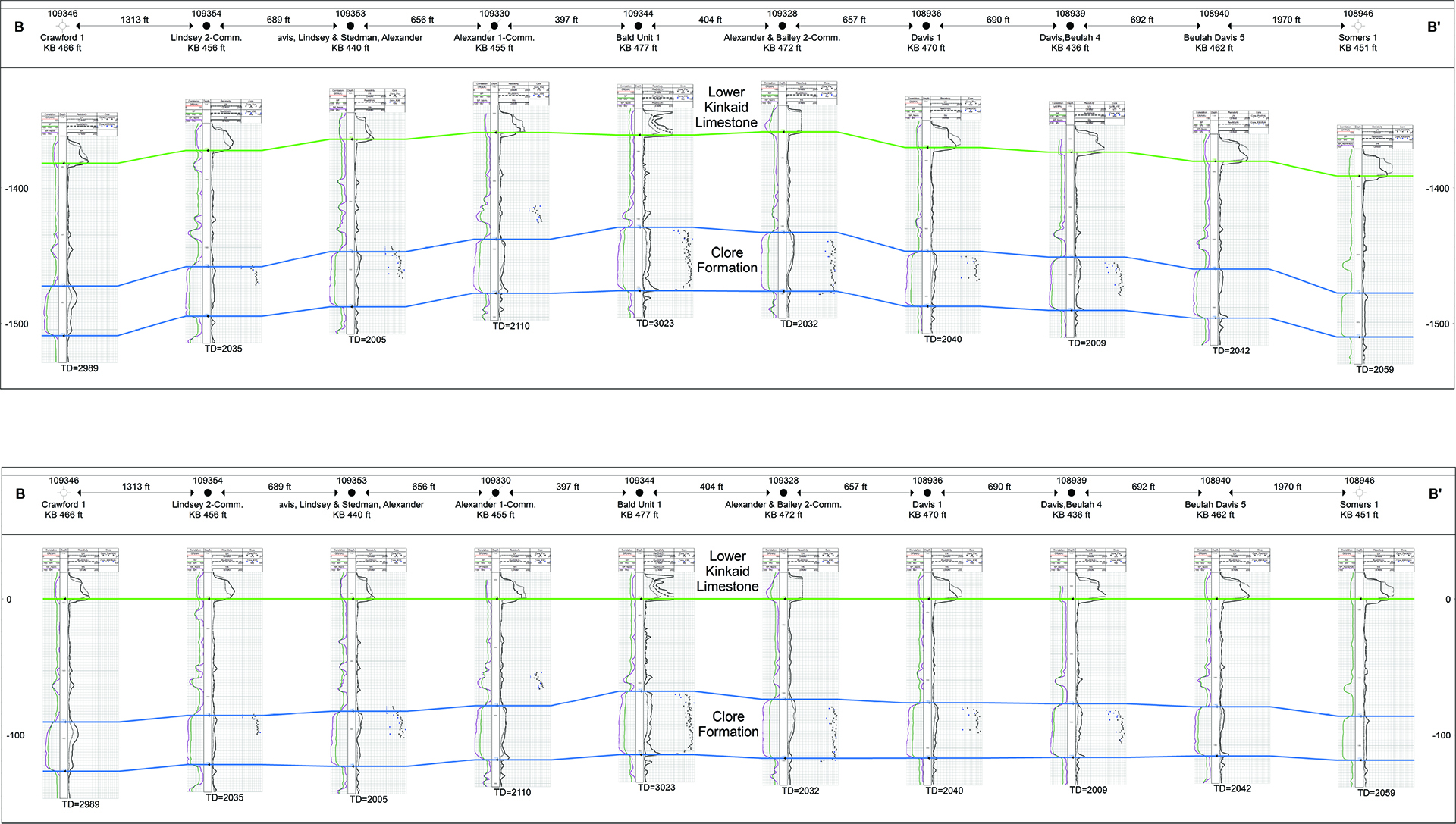

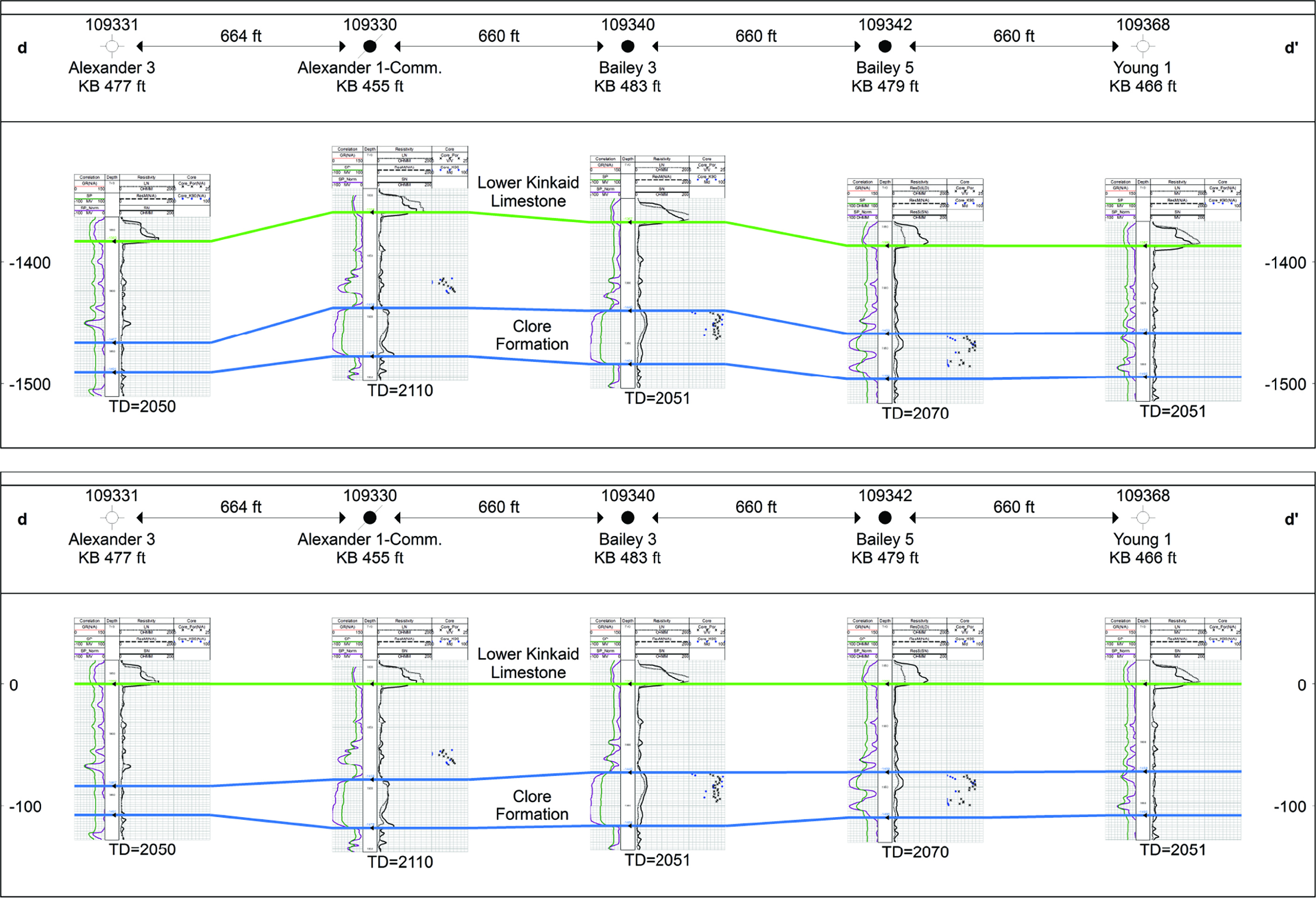

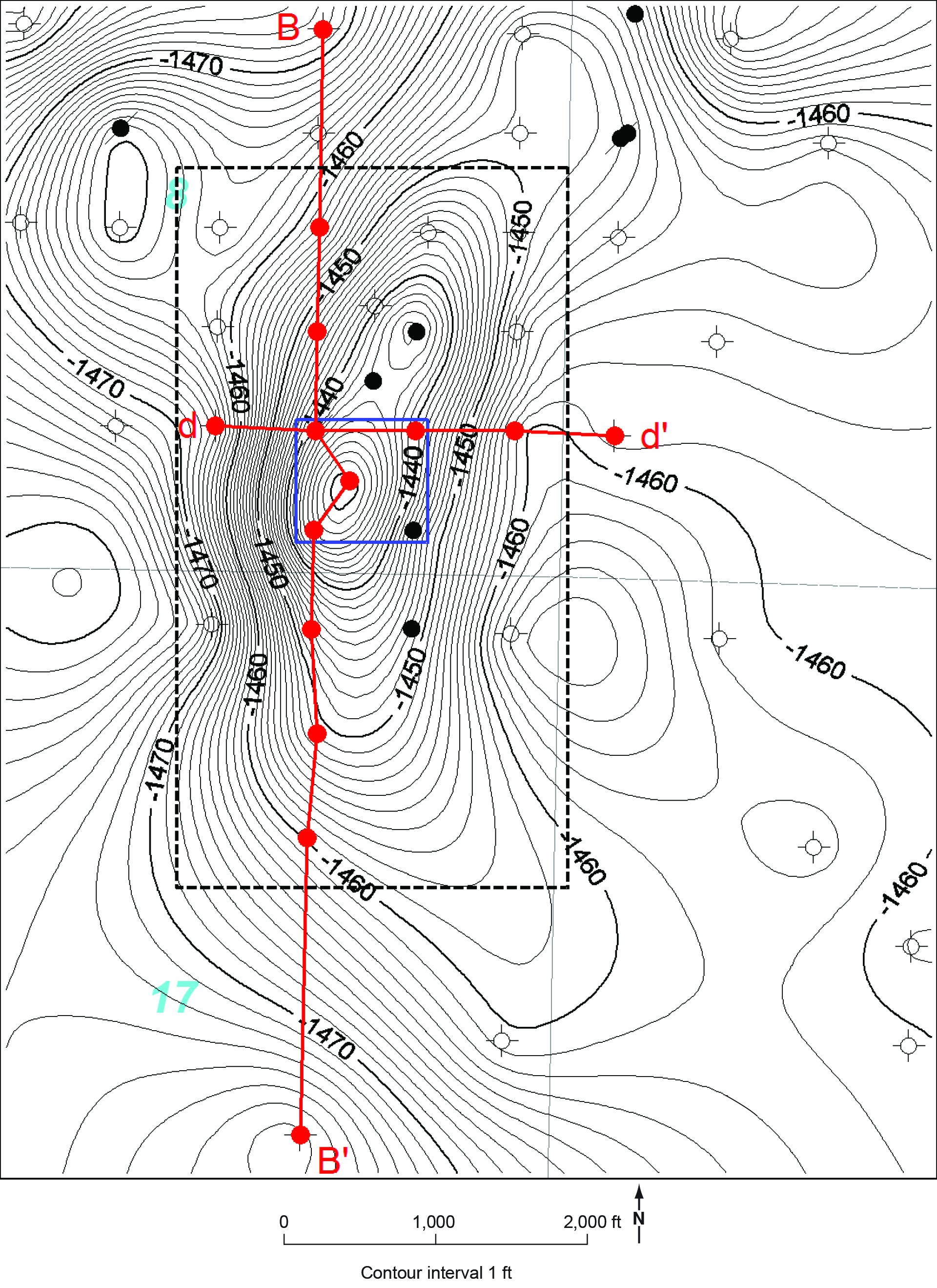

Reservoir core analyses from 15 wells were supplied by the field operator, showing average core porosity of 19% and average core permeability of 1.46 × 10 to 13 m2 (148 millidarcies [mD]). Geophysical log data from 40 wells in the field were used to generate cross-sections, structure, and isopach. A geocellular model of the reservoir was developed from the characterization efforts to estimate CO2-EOR and storage capacity and to quantify the distribution of CO2 in the subsurface.

Main Research Q&As Discovered

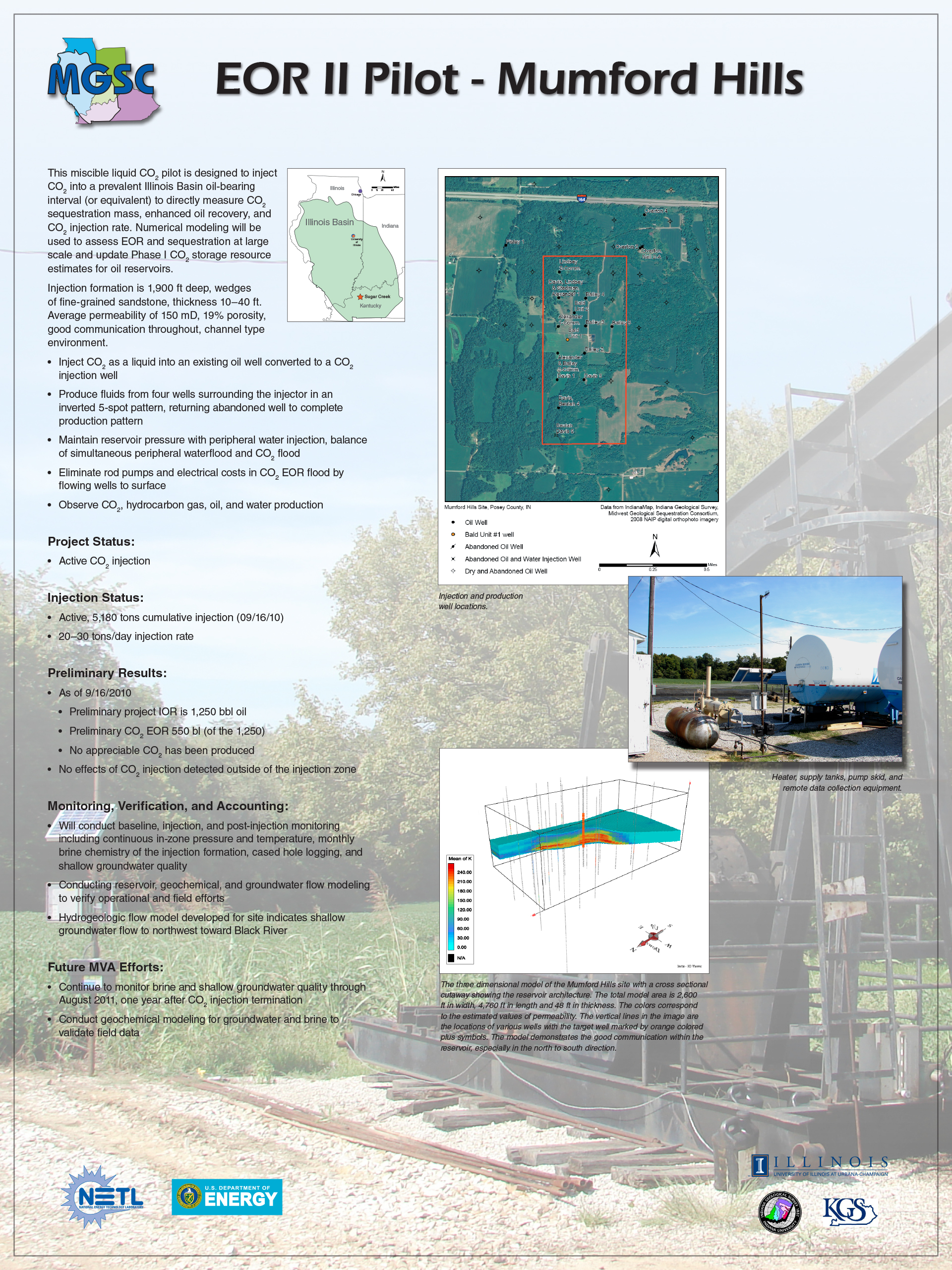

The miscible carbon dioxide enhanced oil recovery (CO2-EOR) II pilot study injected into the Mississippian Clore Formation with the objective to validate the CO2 storage and EOR estimates from the Phase I assessment.

In Mumford Hills, the Clore Formation is fine-grained, elongate sandstone 5 to 6 meters (15 to 20 feet) thick with core characteristics indicative of fluvial or deltaic channel environment. A total of 6,300 metric tons of liquid CO2 was injected into a converted oil production well to a depth of approximately 580 meters (1,900 feet) at a rate of 18.1 to 31.8 metric tons per day over a 12-month time period (September 3, 2009, through December 14, 2010). Fluids were produced and monitored from four surrounding wells (inverted five-spot pattern). Estimated improved oil recovery was 2,590 barrels. Model projection of full-field CO2 injection over 20 years shows the potential for 12% (170,000 stock tank barrel [stb]) incremental oil recovery.

An estimated 27 metric tons of CO2 were produced at the surface, representing 0.5% of the injected CO2. Consequently, 99.5% of the injected CO2 was stored at the Bald Unit oil field after nine months of post-CO2 injection monitoring. The potential CO2 storage is estimated to be 193,600 to 277,450 metric tons. Test results showed that a portion of the injected CO2 is moving into the water-saturated portion of the Clore immediately below the oil reservoir. Assuming 100% recycling of produced CO2, the CO2 storage efficiency factor of the Clore sandstone of the Bald Unit oil field is 130 to 150% of hydrocarbon pore volume, which is much higher than the Midwest Geological Sequestration Consortium (MGSC) Phase I projected results.

Lessons Learned

Real operational problems were encountered at the Mumford Hills pilot site, which improved the Midwest Geological Sequestration Consortium’s (MGSC) general understanding of carbon dioxide (CO2) enhanced oil recovery (EOR) field deployment challenges. One recommendation from the MGSC work is that a longer pre-injection monitoring period is needed to more accurately assess baseline conditions prior to injection. Additional single-well production testing to more accurately constrain oil and water production could improve reservoir models. The lack of consistent and reliable CO2 supply and delivery to the injection site had adverse impacts on oil mobility and overall EOR results; CO2 supply is an understandable issue, given the lack of infrastructure, that can now be addressed with regional carbon capture and storage (CCS) development. In regard to potential storage, tests indicated a portion of the injected CO2 moved into the water-saturated portion of the Clore immediately below the oil reservoir. Good vertical communication in the reservoir, in conjunction with an increase in relative and absolute permeability to CO2 with depth, confirm the potential for stacked storage and EOR in the Illinois Basin.

Story of Interest

Injection of carbon dioxide (CO2) occurred September 3, 2009, through December 12, 2010, with a single significant interruption of approximately three months when CO2 injection stopped due to winter road restrictions. From January 15 through April 15, 2010, some township roads have load-limit restrictions established to prevent damage during periods of thawing and freezing by heavy truck loads. Township road commission can grant access to specific locations on a case-by-case basis. Because oil was sold year-round at the Bald Unit oil field, it was thought that there was at least one road to the Bald Unit without winter road restrictions. After site selection and pre-injection work had begun, it was learned that that the township road commissioner had granted prior approval for oil sales to be limited to one semi-truckload every one to two months. Daily truckload deliveries of CO2 during the period of winter road restrictions were not allowed.

Geologic Details

The miscible carbon dioxide (CO2) enhanced oil recovery (EOR) II pilot study injected into oil-producing horizon of the Bald Unit within the Mumford Hills oil field, Posey County, Indiana. The injection reservoir was the Mississippian Clore Formation. The Clore Formation consists of three members described as a lower limestone/shale interval; a middle sandstone and shale interval called the Mount Pleasant Member (Indiana) and the Tygett Sandstone Member (Illinois); and an upper shale and limestone interval. The Clore Formation was deposited in a shallow marine to coastal terrestrial environment. In Mumford Hills, the Clore Sandstone is approximately 579 meters (1,900 feet) deep, very fine to fine-grained, and occurs in elongate beds of shaly sandstone a few feet thick to intervals of massive sandstone wedges as much as 15 meters (50 feet) thick. The elongated, thick sandstone geometry of the isopach map, the geophysical log character profiles, and the core characteristics all indicate the Clore sandstone was deposited in a fluvial or deltaic channel environment. The Clore sandstone has average permeability of 150 millidarcies (mD), 19% porosity, good communication throughout the reservoir with a strong northeast to southwest trend, and an elongated, lenticular geometry found in many oil-bearing formations of similar age in the Illinois Basin.

Links to EDX

Midwest Geological Sequestration Consortium, Phase II, Enhanced Oil Recovery Pilot Project, Mumford Hills Oil Field, Posey County, Indiana

The Midwest Geological Sequestration Consortium (MGSC) carried out a small-scale carbon dioxide (CO2) injection test in a sandstone within the Clore Formation (Mississippian System, Chesterian Series) in order to gauge the large-scale CO2 storage that might be realized from enhanced oil recovery (EOR) of mature Illinois Basin oil fields via miscible liquid CO2 flooding.