- x

- Loudon EOR I: Single-Well Test

- Mumford Hills EOR IIL Liquid CO2

- Sugar Creek EOR III: Immiscible Test

- Tanquary Coal Test

Carbon Storage Atlas

- Why this Location

- Main Research Q&As Discovered

- Lessons Learned

- Field Site Story of Interest

- Geologic Details

- Links to EDX

- Sites

Why this Location

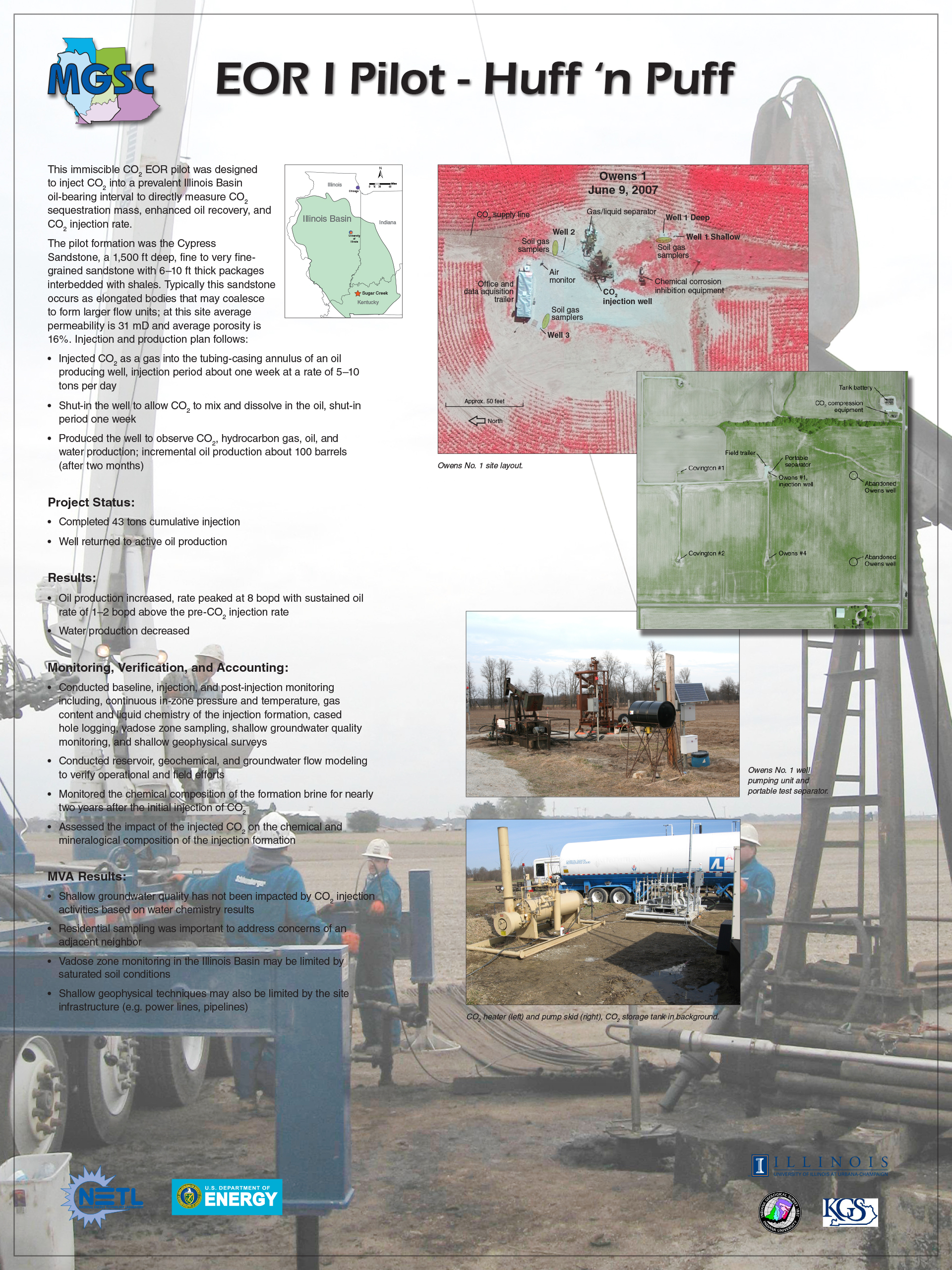

A major challenge to the Midwest Geological Sequestration Consortium’s (MGSC) first Phase II enhanced oil recovery (EOR) pilot project was selection of a suitable site. Although many Illinois Basin operators were interested in the potential of EOR utilizing carbon dioxide (CO2), the lack of any existing CO2 injection infrastructure and concern of CO2 corrosion in existing equipment presented operational risk. After significant negotiations with operators and due diligence for surface operations and subsurface suitability, Loudon oil field in Fayette County, Illinois, was selected.

The Loudon oil field provided a secure, accessible, mature field with favorable well distribution, oil production history, well construction and completion, and producing a formation in the Mississippian Cypress Sandstone with a depth, pressure, temperature, and reservoir properties conducive to a CO2-EOR immiscible study. A CO2 huff n’ puff was selected because of the simple design and execution at the C. Owens #1 well within the southern part of the Loudon oil field.

Main Research Q&As Discovered

The immiscible carbon dioxide enhanced oil recovery (CO2-EOR) I pilot study injected into the Mississippian Cypress Sandstone to estimate the incremental oil recovery due to CO2 injection and the volume of CO2 required for successful EOR in a mature Illinois Basin oil field. This pilot was designed to measure and record data that could be used to calibrate a reservoir simulation model. Secondary objectives were successful field testing of the injection equipment and the implementation of injection and environmental monitoring plans.

In the Loudon oil field, the Cypress Sandstone is very fine to fine-grained sandstone consisting of thin (2 to 3 meters [6 to 10 feet]), lenticular-stacked sand bodies separated by shale interbeds with potential for net sandstone thicknesses up to 30 meters (100 feet) in areas where the sand bodies may coalesce. In the summer of 2007, a total of 39.1 metric tons of CO2 was injected into a converted oil well to a depth of approximately 460 meters (1,500 feet) over a one-week period at a rate of 4.5 to 9.1 metric tons per day. A shut-in period of one week was observed before the well was returned to active production. During the first week of production post shut-in, the well had a maximum daily rate of 8 barrels of oil per day (bopd) (1.3 m3), but declined over the next couple of weeks to 3 to 5 bopd (0.48 to 0.79 m3). Oil production increased to 1 to 2 bopd above pre-injection production of 0.5 to 1.0 bopd (0.079 to 0.16 m3). Over two months, the well was estimated to produce approximately 100 bopd (16 m3) above the pre-injection forecast for oil production. Approximately two incremental barrels of oil were produced per 0.91 metric tons of injected CO2. Water rate was decreased, and overall well behavior was improved long-term. A major concern of Illinois Basin oil field operators, prevention of CO2 corrosion, was effectively achieved with chemical batch and continuous treatments.

Lessons Learned

There were approximately two incremental barrels of oil produced per 0.91 metric tons of injected carbon dioxide (CO2). Water rate was decreased and overall well behavior was improved long-term. A major concern of Illinois Basin oil field operators – the prevention of CO2 corrosion – was demonstrated. Effective control was achieved with chemical batch and continuous treatments. Use of temperature to control rate at the in-line heater increased injection during the daytime hours.

Vadose zone monitoring, verification, and accounting (MVA) in the Illinois Basin may not be feasible due to saturated soil conditions near the surface. Use of shallow geophysical survey techniques in oil fields may be less applicable due to buried pipelines between wells and above-ground electrical lines. Gas sampling of the casing gas was important and necessary to quantify the CO2 production and corrosion potential. Importantly, residential groundwater monitoring alleviated concerns of a landowner when excessive odor in a water well was suspected of being CO2 related.

Story of Interest

One of the local residences near the Loudon huff n’ puff pilot site reported complaints about odor and taste problems with their groundwater from a shallow bored well. The project took a pro-active role in helping the resident determine the source of the problem and to make remediation recommendations. Water samples were collected and analyzed for chemical and bacteriological constituents. Based on chemical and bacteriological analysis of their water, the likely source of the odor/taste problem was related to iron and sulfate-reducing bacteria. Chemical water quality data suggest that activities involving the huff n’ puff pilot were not impactful to the shallow groundwater in the area. Importantly, residential groundwater monitoring alleviated concerns of a landowner when excessive odor in a water well was suspected of being carbon dioxide (CO2)-related.

Geologic Details

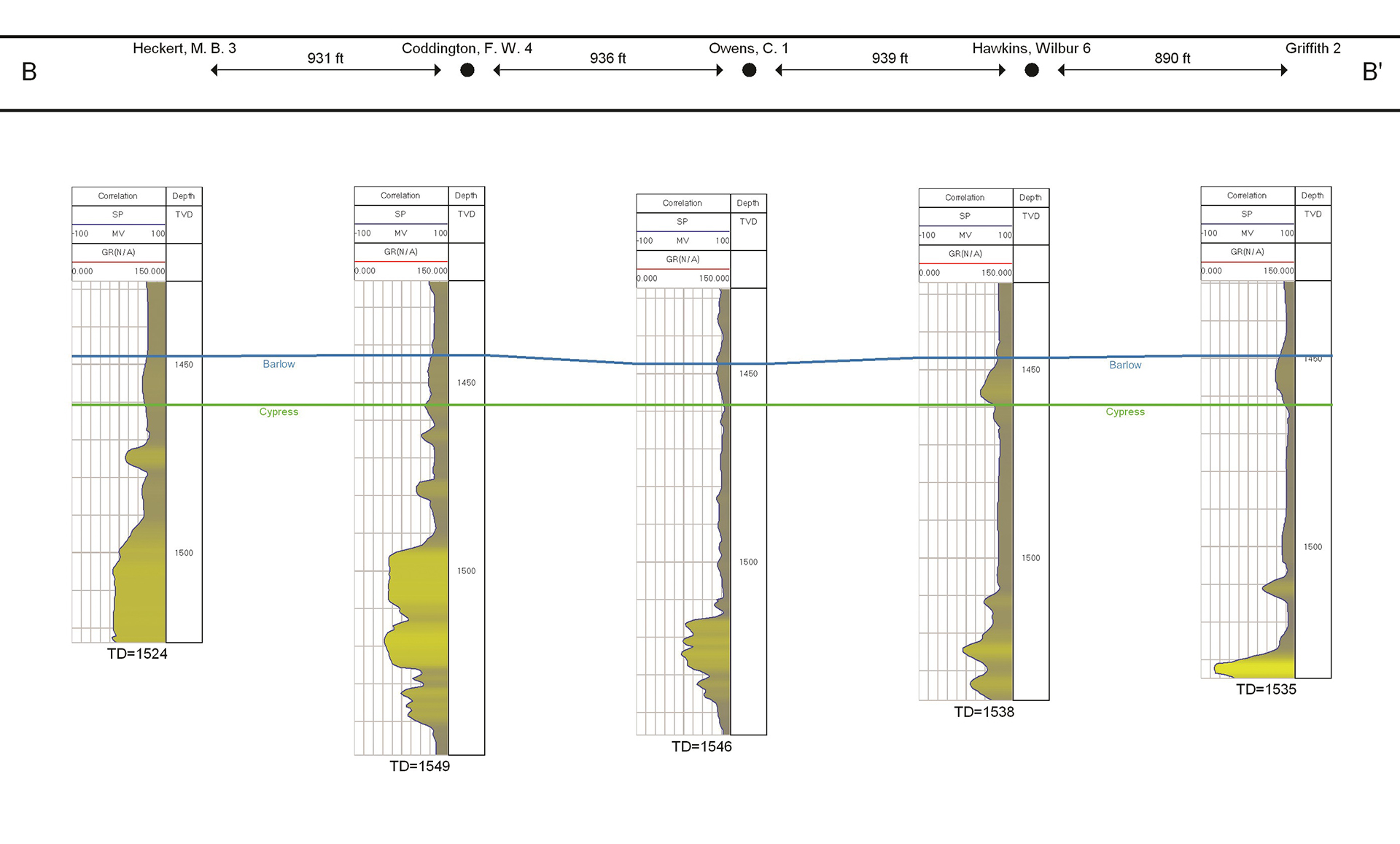

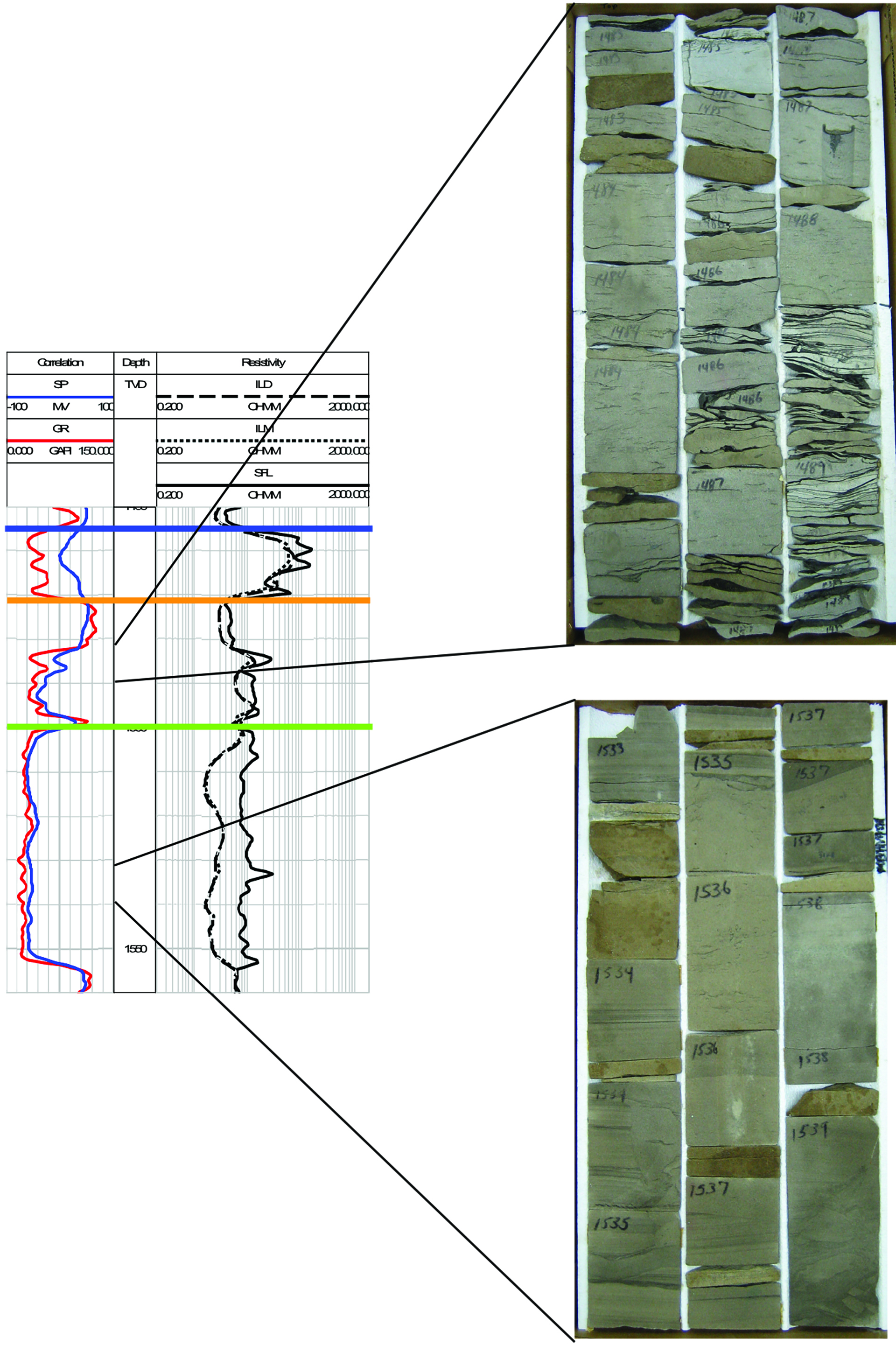

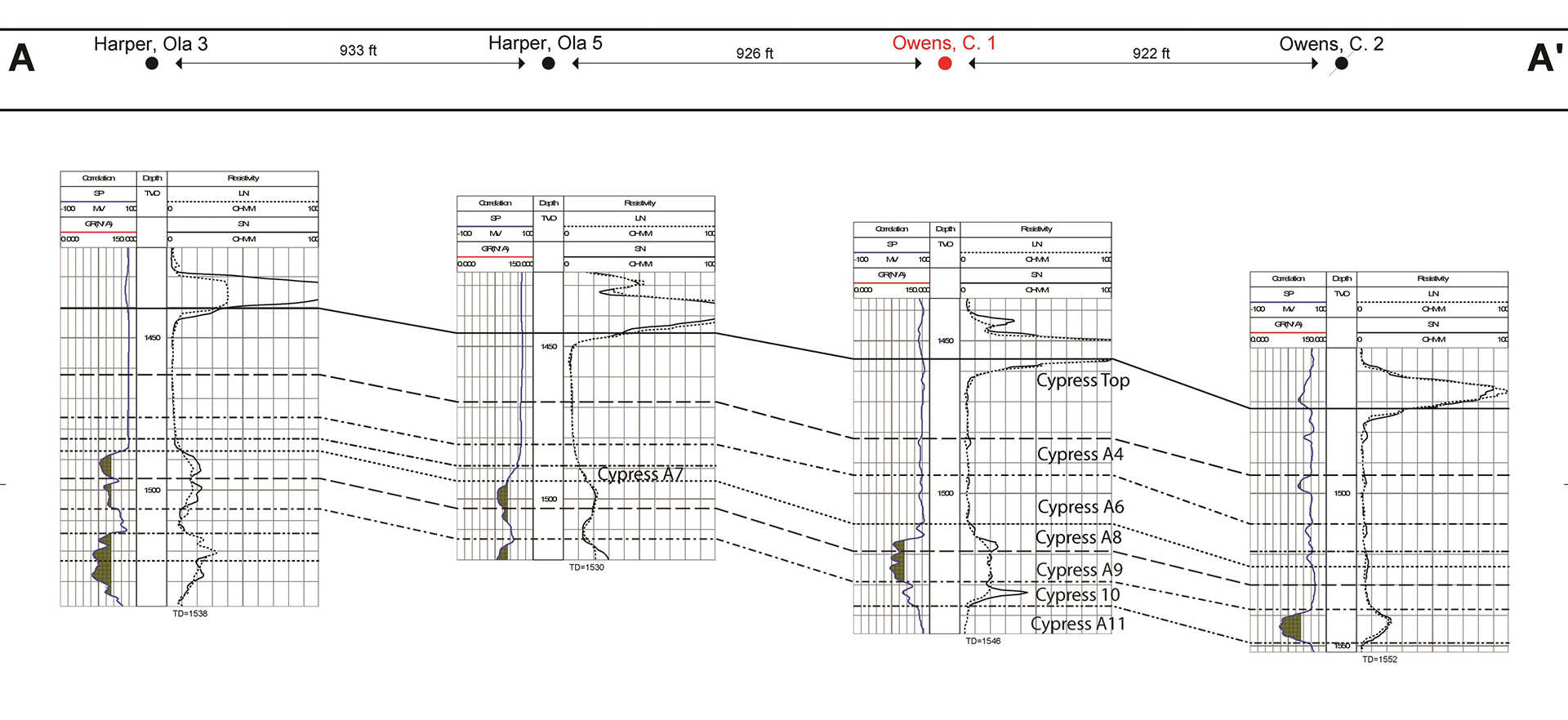

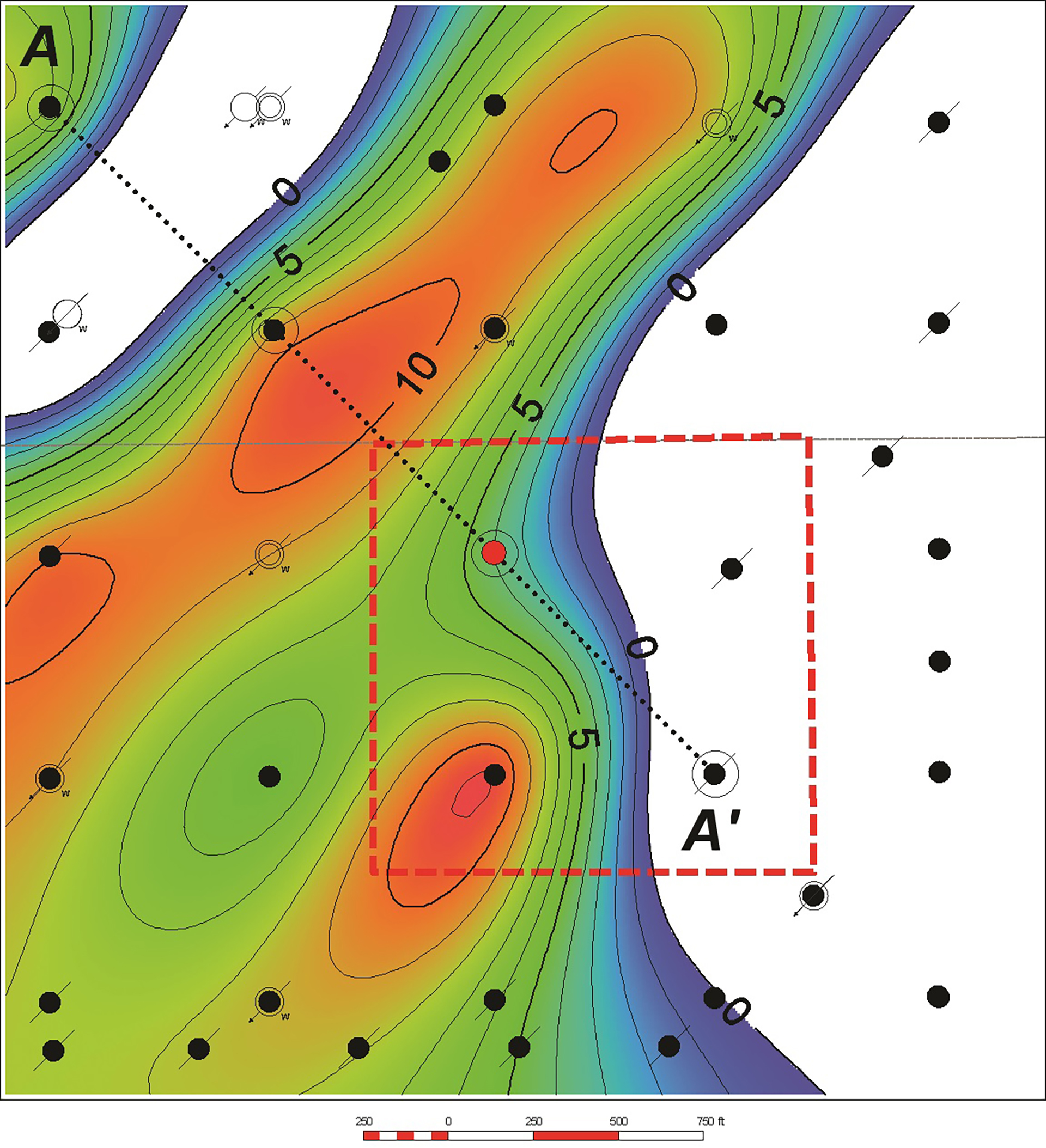

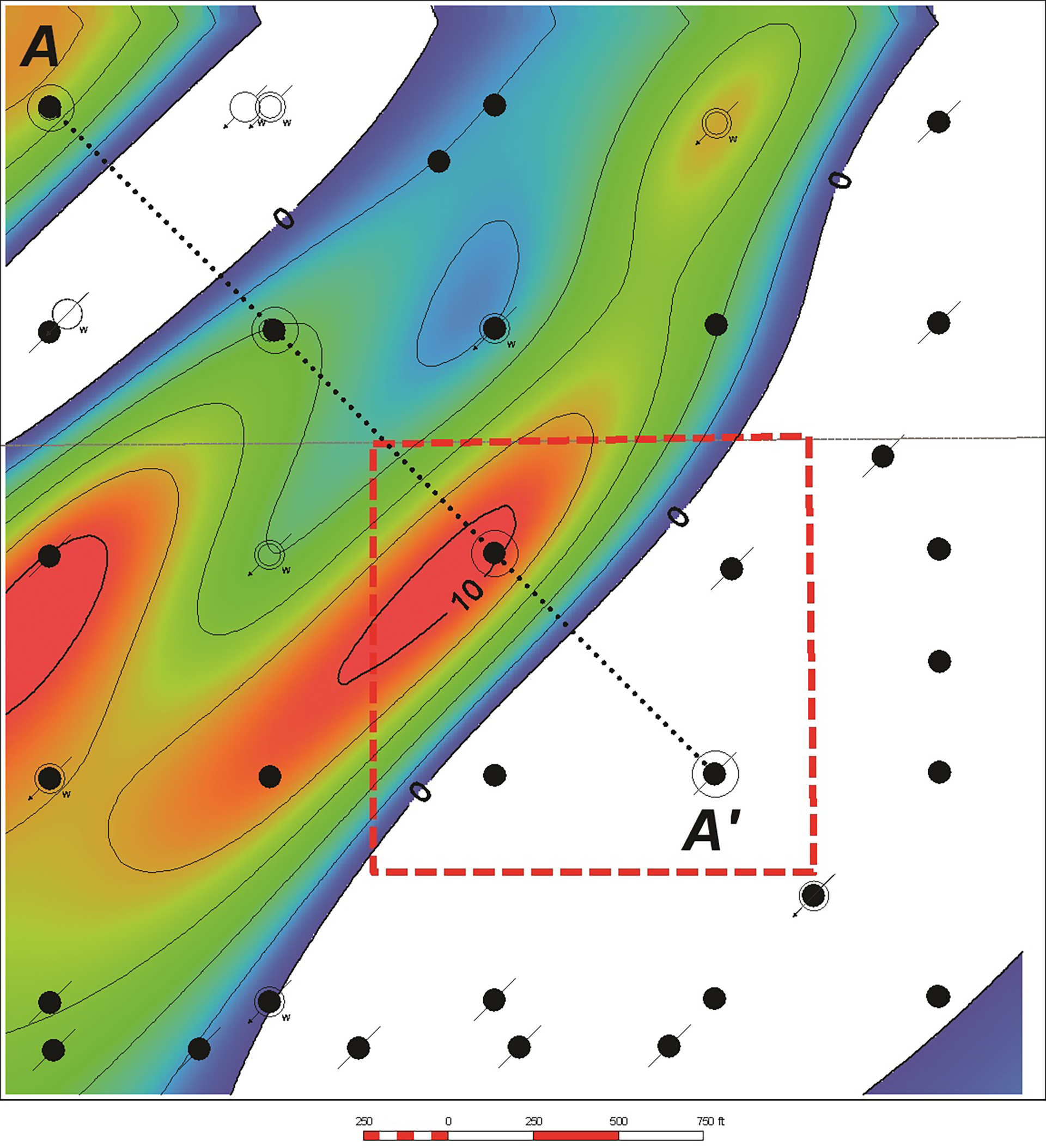

The immiscible carbon dioxide (CO2) enhanced oil recovery (EOR) I pilot huff n’ puff study injected into the Owens #1 well in southern Loudon Oil Field, Fayette County, Illinois. The injection reservoir was the Mississippian Cypress Sandstone. In the Owens lease, the Cypress sandstone is approximately 457 meters (1,500 feet) deep, very fine to fine-grained sandstone consisting of thin (2-3 meters [6-10 feet]), lenticular stacked sand bodies separated by shale interbeds with potential for net sandstone thicknesses up to 30 meters (100 feet) in areas where the sand bodies may coalesce. Log signatures and core analysis suggest that the Cypress Sandstone in the Owens #1 is indicative of fluvial-deltaic environment. Nearby cores from the Heckert lease south of the Owens lease were taken from Cypress sandstones that change facies to a thick-bedded, massive sandstone body that is informally referred to as the Heckert facies sandstone. Cypress reservoirs outside of the Heckert facies are typically small, lenticular pods that coalesce to approximately 81 hectares (200 acres) in area and are individually up to 3 meters (10 feet) thick. These reservoir pods commonly stack vertically to more than approximately 6 meters (20 feet) thick with thin interbedded shales and shaly sandstones that compartmentalize the reservoirs into multiple, unconnected flow units ideal for pilot-injection studies.

Links to EDX

Midwest Geological Sequestration Consortium, Phase II, Enhanced Oil Recovery Pilot Project, Loudon Oil Field, Fayette County, Illinois.

Enhanced Oil Recovery I: Loudon Single-Well Huff n’ Puff: Final Report

A carbon dioxide (CO2) huff n’ puff was selected as the Midwest Geological Sequestration Consortium's (MGSC) first Phase II enhanced oil recovery (EOR) pilot project because of its simplicity of design and execution. A huff n’ puff is the injection of CO2 in the tubing-casing annulus of an oil-producing well.