Advanced Energy Materials

Providing Innovative, Cost-Effective Materials Solutions To Enable Affordable, Reliable and Secure Energy Technologies

The Advanced Energy Materials program focuses on unleashing domestic energy production and use by improving high-temperature power generation technologies, particularly advanced turbines for efficient and low-cost electricity generation from domestic natural gas (NG). While past innovations like advanced welding, ceramic matrix composites/environmental barrier coatings, and the advanced-ultrasupercritical program have aided cycling power plants, current materials and methods still require improvement in durability, operational flexibility and longevity when used in extreme conditions.

Research challenges in advanced energy materials include:

- Understanding materials performance in high-temperature, high-pressure and corrosive fossil energy environments.

- Developing facilities for testing materials and components under realistic fossil fuel environments.

- Developing advanced manufacturing methods for high-performance materials and computational materials modeling as enabling technologies.

- Reducing new material development time and cost.

Efforts within the Advanced Energy Materials program focus on:

- Refining advanced materials and optimizing manufacturing processes to withstand the harsh working environment such as high-temperature, high-pressure and corrosive environments.

- Prioritizing durability, reliability and cost-effectiveness.

- Developing more robust joining and welding techniques.

- Demonstrating scalable manufacturing of these materials, transitioning from prototyping to industrial-scale production.

- Integrating emerging advanced manufacturing approaches.

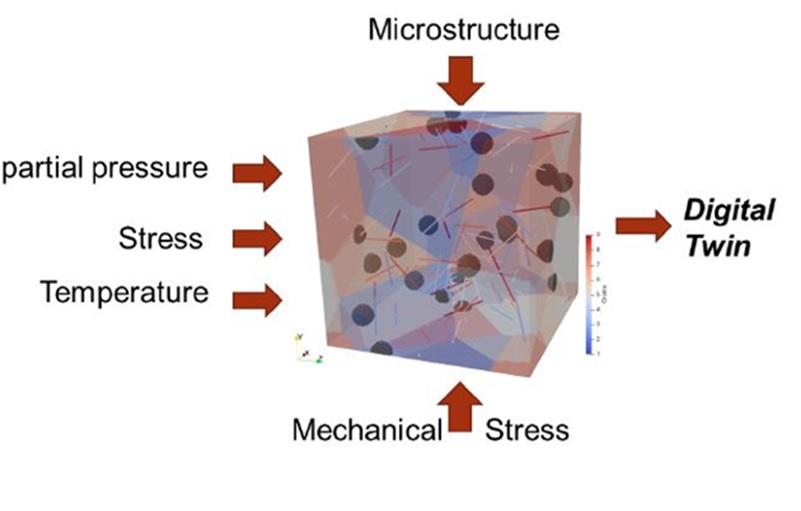

Current programs like eXtremeMAT have developed computational tools to predict the impact of microstructure and alloy chemistry on the creep behavior of alloys. These models can be used to accurately predict the remaining lifespan of components during service and improve the reliability of energy systems. Alloy development efforts should shift focus to include investments in refining and optimizing existing high-performance alloys to meet the specific operational demands of power applications.

The program will offer on-demand technical assistance to overcome materials-related barriers preventing the maturation and commercialization of advanced energy technologies. This support will focus on NG-based technologies crucial for both baseload and peaking power generation. It will have direct applications benefiting grid systems, data centers, well-head power generation, and other energy conversion networks.

Key focus areas include:

- Developing and optimizing advanced materials and manufacturing processes using computational materials modeling.

- Refining advanced materials and optimizing manufacturing processes for demanding environments, with a focus on durability, reliability and cost.

- Developing robust joining and welding techniques, demonstrating scalable manufacturing from prototyping to industrialization, and integrating advanced manufacturing approaches.

- Continuing programs like eXtremeMAT that develop computational tools to predict the impact of microstructure and alloy chemistry on alloy creep behavior.

- Developing a robust domestic materials supply chain that includes good-paying jobs for the American workforce.

- Developing low-cost, high-performance alloys to increase domestic energy use and production.

Research Areas

Computational Materials Design

High Temperature Material Supply Chain

.jpg)

Advanced Manufacturing

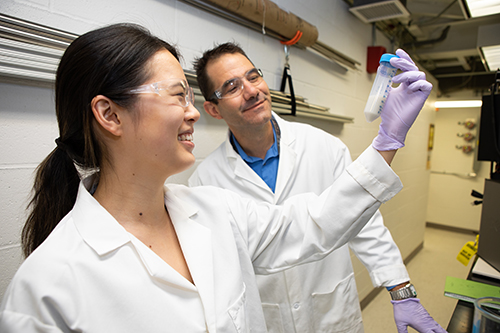

The eXtremeMAT project addresses materials challenges by harnessing the unparalleled computational and experimental materials science expertise and capabilities within the DOE national laboratory system, into an integrated team aimed at improving heat-resistant alloys.

DOE Fossil Energy supports the High-Performance Computing for Materials (HPC4Mtls) program as part of DOE’s High-Performance Computing for Energy Innovation Program. HPC4Mtls accelerates industry discovery, design and development of materials in energy technologies by enabling access to computational capabilities and expertise in the DOE laboratories.

NETL researchers develop and maintain the Energy Data eXchange (EDX) to support private collaboration for ongoing research efforts, and technology transfer of finalized DOE and NETL research products. EDX offers a secure environment for multiorganizational research teams to share, build and collaborate online tools, data and information.

NETL’s Systems Energy Analysis group conducts a variety of energy analyses to identify and evaluate promising R&D opportunities.

The Advanced Energy Materials program also participates in the multiyear collaboration with the United Kingdom's Department for Energy Security and Net Zero and DOE materials technologies. The partnership’s objective is to share and develop knowledge and expertise in high-temperature materials for advanced power plant applications.

View Project