Reduction and removal of carbon dioxide (CO2) from the atmosphere are key objectives in the climate change challenge. NETL has been at the forefront of carbon capture and storage research for decades. Now, its carbon dioxide removal (CDR) technology research is helping set the pace for additional innovations in direct air capture (DAC) and other technological approaches that are focused on attaining the Biden Administration’s goal of a net-zero greenhouse gas emissions economy by 2050 through just and sustainable decarbonization pathways.

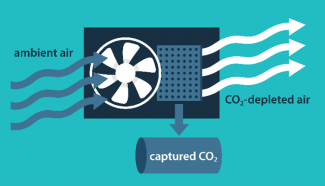

DAC technologies use chemical reactions to pull CO2 directly out of the air independent of point sources. Active DAC contactors use fans or blowers to move the air through the adsorbing materials while passive contactors use wind to move the air across the adsorbing material.

NETL’s CDR Program is fostering applied research and development focused on DAC that includes emerging research in biomass carbon removal and storage, enhanced weathering and mineralization, and ocean-based and terrestrial approaches to remove CO2 that has accumulated in the atmosphere.

Sponsored research supports the Department of Energy (DOE) Carbon Negative Shot — a pathway-neutral “Energy Earthshot” that aims to develop less than $100/net metric ton (tonne) CO2-equivalent (CO2e) removal by 2032, with costs including ongoing monitoring, reporting, and verification (MRV).

Andrew Jones, NETL’s CO2 removal technology manager, explained that DAC technologies “will be critical for counterbalancing the hard to decarbonize sectors like agriculture, shipping, and aviation and addressing legacy emissions. This approach is technically challenging compared to point-source carbon capture systems designed for power plants or industrial facilities due to reduced driving force for separation.”

Common DAC processes employ cyclic absorption (solvents) and adsorption (solid sorbents) processes in engineered contactors. Accelerated natural DAC systems whereby CO2 from the atmosphere reacts with alkaline materials (such as magnesium and calcium) to form solid carbonate minerals are also under development.

The solvent-based approach involves chemical or physical absorption of CO2 from air into a liquid carrier. The absorption liquid is typically regenerated by increasing its temperature or reducing its pressure to break the absorbent CO2 bond. Capture media regeneration can also be induced by employing humidity, electrochemical, and radiation swing mechanisms.

Sorbent-based CO2 capture involves the chemical or physical adsorption of CO2 using a solid sorbent. Like solvents, solid sorbents are usually regenerated by increasing temperature or reducing pressure to release the captured CO2.

The CO2 captured from the air can be securely stored in deep geological formations or even used to produce valued-added products to create negative emissions (i.e., more carbon is removed from the atmosphere than generated).

A major advantage of DAC is its flexibility in siting. A DAC plant can be situated in any location that has a low-carbon energy source to power its operation and accessibility to a secure CO2 storage resource or conversion opportunity.

Because DAC technologies have not yet been demonstrated at the scale necessary for major climate impact, private sector interest, federal funding legislation, and even international organizations are focusing on DAC technology development.

DAC support was highlighted in the Infrastructure Investment and Jobs Act, also known as the Bipartisan Infrastructure Law (BIL), which dedicated $3.5 billion for development of the regional DAC hubs and $115 million for pre-commercial and commercial DAC technology prize competitions.

NETL research is aiming to advance DAC technologies through further discovery and optimization of new capture materials that promote rapid CO2 capture with high dynamic CO2 capacity; structured material systems and component designs; and integrated processes that leverage the material’s unique characteristics to maximize volumetric CO2 capture productivity, while reducing pressure drop, heat and power requirements, and capital and operating costs.

R&D is focused on processes and materials that will increase the amount of CO2 removed by DAC, decrease the cost of materials, and improve energy efficiency. The CDR Program also emphasizes a robust analysis of life cycle impacts and a deep commitment to environmental justice.

“Our CO2 removal program tests breakthrough materials and components, conducts field validations of integrated processes, and provides leadership and guidance on process modeling and analysis, techno-economic assessments and life cycle analysis,” he said.

NETL is supporting DOE DAC efforts with initiatives that include creation of regional hubs, launching prize competitions, and development of a state-of-the-art NETL research center.

According to Jones, NETL’s $20 million DAC Center will test capture materials and resolve scale-up issues while supporting private sector technology partnerships for maturation and implementation. NETL held a collaborative workshop to discuss the new center’s capabilities and ensure it will serve as an asset to DAC technology developers when it goes live in spring 2024.

David Miller, Ph.D., NETL’s Chief Research Officer, stresses that “Advancing the development of CDR approaches will help us meet our net-zero emissions targets and address the global climate crisis — keeping in mind that these technologies are required in addition to economywide deployment of carbon capture and other low- and zero-carbon solutions that reduce, and ultimately eliminate, greenhouse gas emissions from existing sources. NETL’s history of innovation makes it a great choice for a DAC test center to support the development of technologies that will be needed to achieve a fully net zero economy by 2050.”

NETL is a U.S. Department of Energy national laboratory that drives innovation and delivers technological solutions for an environmentally sustainable and prosperous energy future. By leveraging its world-class talent and research facilities, NETL is ensuring affordable, abundant and reliable energy that drives a robust economy and national security, while developing technologies to manage carbon across the full life cycle, enabling environmental sustainability for all Americans.