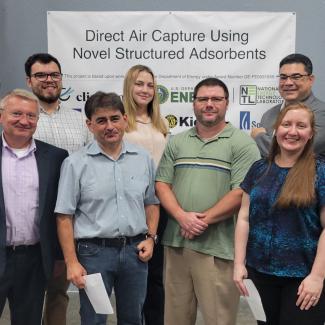

In the image above, DOE and NETL representatives, from left, Andrew Hlasko, Zachary Roberts, Dan Hancu, Krista Hill, Andrew Jones, José Figueroa and Nicole Shamitko-Klingensmith visited Electricore in Fountain Valley, California, to discuss a project to capture CO2 from the air using a novel solid sorbent laminate filter technology. The group received a tour of the test plant and a project status update.

NETL and other U.S. Department of Energy (DOE) representatives toured six sites during four days in California where projects are being developed with the Lab’s oversight and support to capture carbon dioxide (CO2) and lower atmospheric levels of the greenhouse gas.

The tour stops focused on technologies supported by both the Point Source Carbon Capture and the Carbon Dioxide Removal programs, which are advancing the next generation of carbon capture systems to help achieve a 100% carbon emissions-free electricity sector in the United States by 2035 and a net-zero clean energy economy by 2050.

“Our recent trip to California provided opportunities to see first-hand how our partners are working to meet these goals and mitigate technical, operational and scale-up risks and issues,” said Nicole Shamitko-Klingensmith, a project manager on the Point Source Carbon Capture Team.

Visiting these capture technology projects in California helped the NETL/DOE teams “appreciate and understand the technical and project-related challenges so we can work with our industry partners to keep projects moving forward and develop the innovative, cost-effective technologies needed to address climate change,” Shamitko-Klingensmith said.

Completing the tour with Shamitko-Klingensmith were two other members of the Point Source Carbon Capture Team, José Figueroa, supervisor, and Krista Hill, project manager, as well as NETL’s Zachary Roberts, project manager, Carbon Dioxide Removal and Conversion Team, and Andrew Jones, technology manager, Carbon Dioxide Removal.

The NETL contingent was joined by DOE’s Dan Hancu and Andrew Hlasko, senior program managers, Point Source Carbon Capture.

The sites visited were:

-

The Electric Power Research Institute facility in Palo Alto is leading an effort to field-test an advanced solvent developed at Pacific Northwest National Laboratory. Solvent-based CO2 capture involves chemical or physical absorption of CO2 from a gas into a liquid carrier. The solvent will be scaled-up and tested using both coal- and natural gas-derived flue gas. Additional testing is planned at the DOE-sponsored National Carbon Capture Center.

-

AirCapture LLC, based in Berkeley, develops a modular direct air capture (DAC) technology that uses waste heat from manufacturing plants to provide energy for the capture process. DAC is a CO2 removal technology that captures CO2 from ambient air rather than from power plant or industrial facility flue gas. AirCapture partnered with the Southern States Energy Board to advance the development of the technology for future scale-up in the Direct Air Capture Recovery of Energy for Carbon Capture, Utilization and Storage Partnership (DAC RECO2UP).

-

Researchers at Membrane Technology and Research (MTR) in Newark discussed several ongoing, federally funded projects. The main focus of the meeting was on the Large Pilot Testing of the MTR Membrane Post-Combustion CO2 Capture Process. For this pilot, MTR will construct and operate a membrane-based carbon capture system capable of capturing 150 metric tons of CO2 per day at the Wyoming Integrated Test Center at Basin Electric’s Dry Fork Station in Gillette, Wyoming. This project is currently in the detailed design and construction phase, which is expected to be completed by the end of 2023.

-

The NETL/DOE group stopped at SRI International in Menlo Park for an overview of several projects. The priority discussion was on the 0.5 megawatt electric (MWe) equivalent engineering-scale demonstration of a Mixed-Salt Process for CO2 Capture. The process uses a solvent made from readily available, inexpensive materials and employs a novel flow configuration to improve absorption kinetics, minimize solvent emissions and reduce water usage.

-

In Fountain Valley, Electricore, Svante, and Climeworks provided updates on a process that employs Svante’s novel solid sorbent laminate filter technology integrated with Climeworks’ DAC technology in which CO2 from the air is chemically bound to a solid sorbent material. The sorbent is then regenerated using vacuum- and temperature-swing desorption. The objective is to advance DAC technology and reduce capture costs of removing CO2 from air by accelerating cycle times through the use of structured adsorbent beds.

-

At the Kern River Oil Field in Bakersfield, the NETL contingent received an update on Chevron’s Natural Gas Carbon Capture Technology Testing Project. This engineering-scale project uses Svante’s VeloxoTherm™ carbon capture technology to remove CO2 from the flue gas of natural gas-fired steam generators. Researchers constructed a carbon capture unit capable of capturing 30 metric tons per day of CO2 under steady-state conditions. Chevron has contributed additional project funding to cover pandemic-related cost increases. Chevron was approved to begin the final budget period in October 2022 to validate the technology under a variety of CO2 concentrations.

NETL is a DOE national laboratory that drives innovation and delivers technological solutions for an environmentally sustainable and prosperous energy future. By leveraging its world-class talent and research facilities, NETL is ensuring affordable, abundant and reliable energy that drives a robust economy and national security, while developing technologies to manage carbon across the full life cycle, enabling environmental sustainability for all Americans.