NETL-funded research on an approach to recycle hydraulic fracturing water using natural filtration and biogenic activity in specific layers of rock is attracting international attention with a “highly commended” recognition in a global competition sponsored by an acclaimed engineering organization.

The University of North Dakota’s Energy & Environmental Research Center’s Produced Water Management Through Geologic Homogenization, Conditioning, and Reuse (GHCR) project, developed in partnership with the North Dakota Industrial Commission Oil and Gas Research Program) and Nuverra Environmental Solutions, was a finalist in the Oil and Gas category of the 2022 Institution of Chemical Engineers (IChemE) Global Awards.

The project was funded by NETL and the Department of Energy’s Office of Fossil Energy and Carbon Management.

While first place in the competition went to University College London, United Kingdom, for its methane to valuable chemicals research effort, the GHCR research received a “highly commended” designation.

Founded in 1922, UK-based IChemE is the internationally recognized learned society for chemical, biochemical and process engineers. The organization advances chemical engineering’s contribution for the benefit of society.

When hydrocarbons are recovered from oil and gas formations through hydraulic fracturing, significant quantities of high-salinity water are often co-produced. This water is generally referred to as “produced water.”

According to a study by Duke University, “energy companies used nearly 250 billion gallons of water to extract unconventional shale gas and oil from hydraulically fractured wells in the United States between 2005 and 2014…During the same period, hydraulically fractured wells generated about 210 billion gallons of wastewater.”

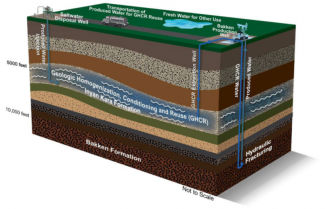

The GHCR concept offers a novel approach to recycling produced water from oil and gas extraction, particularly in the Bakken region of North Dakota. With energy industries’ demand for water expected to double in the coming years, careful management of water is essential to ensuring that local communities have adequate clean water supplies.

NETL’s Joseph Renk, who served as the project officer on the research effort, said that in the GHCR process, produced water is reinjected into the subsurface where it takes advantage of the natural filtration and biogenic activity of geological strata to remove contaminants including suspended solids and organics.

“Lab testing and field samples indicated that North Dakota Inyan Kara sandstone and native formation fluids are able to treat, stabilize and homogenize produced water to a point where it can be recycled and reused,” Renk said. “The recycled water can be reused in hydraulic fracturing to reduce the oil and gas industry’s demand on freshwater.”

The new approach offers a range of other advantages including:

- Reuse of the treated water can relieve formation pressure, which allows new oil wells to be drilled more economically.

- GHCR fluid extraction can extend the life of traditional saltwater disposal wells

- The concept eliminates the need for surface storage of produced water and can use existing infrastructure like pipelines and wells.

- GHCR nearly eliminates the need to manage the highly concentrated brines and naturally occurring radioactive materials typically associated with produced water treatment and reuse.

Water management is a significant technical and economic challenge for sustainable oil and gas production. North Dakota oil production rose to over 1.5 million barrels (MMbbl)/day in 2019. After a brief downturn in oil prices in early 2020, North Dakota oil production recovered to 1.1 MMbbl/day by August 2021.

“Produced water recycling is not yet widespread,” Renk explained. “But as water management continues to be a key focal point in companies’ environmental, social and governance initiatives, focus on water management, including recycling, will continue to increase.”

NETL conducts and supports research on energy resource sustainability efforts that: maximize resource recovery efficiency; reduce environmental impacts; lower exploration and production risks; improve natural gas transportation efficiency and resiliency; and reduce resource production costs.

NETL partners with industry, academia, technology developers, government agencies, and other national laboratories to ensure the effectiveness and efficiency of research projects throughout its portfolio.

NETL is a U.S. Department of Energy national laboratory that drives innovation and delivers technological solutions for an environmentally sustainable and prosperous energy future. By leveraging its world-class talent and research facilities, NETL is ensuring affordable, abundant and reliable energy that drives a robust economy and national security, while developing technologies to manage carbon across the full life cycle, enabling environmental sustainability for all Americans.