NETL has significantly upgraded its computerized tomography (CT) scanning technology to provide researchers with an enhanced tool to look at dynamic processes inside rock cores.

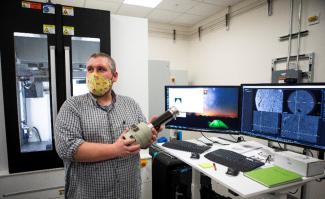

“CT scanning is among the unique capabilities we have refined at NETL to determine, for example, under what conditions carbon dioxide (CO2) generated by fossil energy production and industrial processes can be injected underground safely and permanently stored in rock formations deep within the subsurface to reduce emissions of greenhouses gases into the atmosphere,” said Dustin Crandall, Ph.D., an NETL research engineer.

NETL is positioned to take its expertise in geologic CT scanning to the next level and will soon begin producing higher resolution images of microstructures within rock cores in a significantly shorter period of time.

The technology to accomplish these goals is the 11,646-pound TESCAN DynaTOM CT scanner, the first to be installed in the United States, which arrived at NETL’s Center for Advanced Imaging and Characterization in Morgantown, West Virginia, a year ago.

The center currently operates three scanners that enable characterization of the internal structure of rock cores. Its supporting flow-through instrumentation enables direct measurement of fluid/rock interactions at representative subsurface pressures and temperatures within the CT scanners. These technologies work in tandem to provide characteristic geologic and geophysical information of real materials at real conditions.

Testing of the new equipment is nearing completion. “That’s great news because we continue to receive pallets of rock cores for analysis and expect many more,” Crandall said. “Using this technology, our team will be able to complete scans in 30 seconds, which is up to 30 times faster than our current scanning technology, and complete timely studies that are critical to store CO2 in the subsurface in an environmentally responsible manner.”

CT scanning processes thousands of two-dimensional X-ray measurements taken from different angles to produce three-dimensional images of a scanned object, allowing the user to see inside the object without physically cutting it. Additionally, NETL’s scanning operations are equipped with temperature and pressure controls to enable in-situ flow testing, which can simulate subsurface conditions to evaluate how injected CO2 would move through rock pores and fissures or dissolve with natural brines, mineralize or react with other fluids.

Using CT scanning, researchers can determine porosity, permeability, fracture properties and composition while leaving core samples of dense granites, fragile shales and other types of rocks obtained from the subsurface intact and available for further testing.

The Lab’s new CT scanning technology builds on existing capabilities, positioning NETL to complete high temporal resolution, 4D scanning to determine how fluids and hydrocarbons move through subsurface rock and may cause rocks to dissolve or trigger chemical precipitation or mineralization.

The high-resolution scans will be achieved using a device housed in a lead-lined cabinet and designed to enable imaging equipment to rotate around the stationary sample.

Crandall said the new CT scanning capability also will be used in studies to test the integrity of wellbore cement used in drilling holes. Cement with greater integrity prevents unwanted upward migration of gases and fluids in formations. Such migration poses an environmental risk to overlying groundwater supplies and the potential to release greenhouse gases, such as methane, to the surface.

NETL researchers also will use the advanced CT technology to expand their study of gas hydrates, molecules of natural gas (most commonly methane) enclosed within a solid lattice of water molecules. Gas hydrate deposits are found wherever methane occurs in the presence of water under elevated pressure and at relatively low temperatures, such as beneath permafrost or in shallow sediments along deep-water continental margins. Once thought to be rare, gas hydrates are now believed to occur in vast volumes.

The Lab has developed unique capabilities to obtain and study gas hydrate-bearing sediment core samples. “Methane hydrates have great potential as an energy resource. CT scanning can be used to study how gas hydrants form and dissociate (or break apart) and enhance our understanding of this resource,” Crandall said.

NETL is a U.S. Department of Energy national laboratory that drives innovation and delivers technological solutions for an environmentally sustainable and prosperous energy future. By leveraging its world-class talent and research facilities, NETL is ensuring affordable, abundant and reliable energy that drives a robust economy and national security, while developing technologies to manage carbon across the full life cycle, enabling environmental sustainability for all Americans.