NETL’s project partner Svante Inc. is rapidly scaling up a new sorbent and intensified process technology to capture carbon dioxide (CO2), a greenhouse gas, from power generation and industrial point sources that could significantly lower the capital investment needed to develop carbon capture plants at gigaton scale.

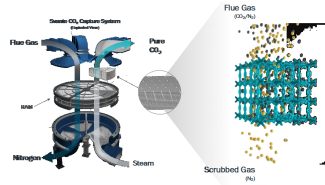

Svante offers companies in difficult-to-abate industries, such as those that produce cement, hydrogen, chemicals, pulp and paper, an engineered solution to rapidly capture CO2 with a unique filter made from nanomaterials called structured adsorbents. These filters are installed in a continuous rotary adsorption machine (RAM) that separates CO2 from flue gas streams and generates high-purity CO2 in about 60 seconds. Captured CO2 can then be stored permanently in the subsurface or reused as a feedstock for value-high chemicals and other applications.

The technology can capture up to 95% of CO2 emitted from power generation and industrial sources using novel solid sorbent materials that act as a sponge for adsorbing CO2. Low-pressure steam is introduced to release the carbon dioxide from the filter, allowing the sorbent materials to rapidly regenerate and repeat the capture process.

“By partnering with Svante and other industries, NETL is working to develop the next generation of advanced CO2 capture concepts and move the technology toward commercial application to lower atmospheric emissions of greenhouse gas,” said Andrew Jones, project manager on the Lab’s Carbon Capture Team.

“Our partnership is driving step-change reductions in both the capital cost and energy requirements for carbon capture for deployment to the existing fleet of energy plants, new plants and industrial facilities to meet the carbon reduction goals of the Biden Administration, which call for net-zero carbon emissions in the energy sector by 2035 and the broader economy by 2050,” Jones said.

In parallel to initial technology maturation and field testing with amine-based structured adsorbents, Svante has formulated the Calgary Framework 20 (CALF-20) metal-organic framework (MOF) to expand its technology offerings to challenging industrial applications. The CALF-20 MOF reacts with CO2 via a weaker physical bond that reduces process steam demand. MOFs also offer improved stability in the presence of oxygen and acidic gases.

Svante has collaborated with BASF, a multinational chemical company, to pioneer the scale-up of CALF-20 MOF using a simple and low-cost water-based process in accordance with green chemistry principles. Scalability and low cost of solid sorbent are imperative to deployment of a cost-effective solution at a climate-relevant scale.

Multiple projects, advancing with NETL oversight and financial assistance, have been launched by Svante to evaluate the nano-filter technology and its use as a lower-cost, energy-efficient process for carbon capture applications.

In September 2020, NETL, through industry partner Electricore Inc., awarded $1.5 million for cost-shared development to support initial engineering analysis for CO2MENT, a first-of-its-kind commercial project to capture up to 1.5 million tonnes of CO2 per year at the Holcim Cement Plant in Florence, Colorado.

NETL also awarded $13 million for cost-shared development to support design, construction and operation of a second-of-its-kind engineering-scale (25 tonnes per day) carbon capture plant at Chevron’s Kern River oil field in California’s San Joaquin Valley.

Both projects are using the transformational CALF-20 MOF sorbent material, which is being field tested (1 tonne per day CO2 capture) at Lafarge-Holcim’s CO2MENT Richmond Project based at a cement plant in British Columbia, Canada.

Svante’s partnership with NETL also is exploring efforts to decarbonize the production of hydrogen (H2) from natural gas through a process called steam methane reforming, which is widely viewed as the lowest-cost, near-term solution to manufacture H2 for use as a clean fuel in a variety of sectors, including transportation.

NETL awarded nearly $1.5 million in October 2021 to complete an initial engineering design study to use Svante solid sorbent post-combustion CO2 capture technology at the Linde Steam Methane Reforming Hydrogen Plant in Houston, Texas.

When coupled with carbon capture capabilities, low-cost H2 sourced from fossil energy feedstocks, such as methane, will significantly reduce the carbon footprint of these processes and enable progress toward H2 production with net-zero carbon emissions. The overall system will be designed to capture approximately 1.1 million tonnes per year net CO2 with 90% or greater carbon capture efficiency while producing H2 with 99.97% purity.

“Such partnerships between NETL and industry are spearheading the advancement of innovative carbon capture technologies and accelerating the transition to a lower-carbon world,” Jones said.

NETL is a U.S. Department of Energy national laboratory that drives innovation and delivers technological solutions for an environmentally sustainable and prosperous energy future. By leveraging its world-class talent and research facilities, NETL is ensuring affordable, abundant and reliable energy that drives a robust economy and national security, while developing technologies to manage carbon across the full life cycle, enabling environmental sustainability for all Americans.