Simulation-Based Engineering

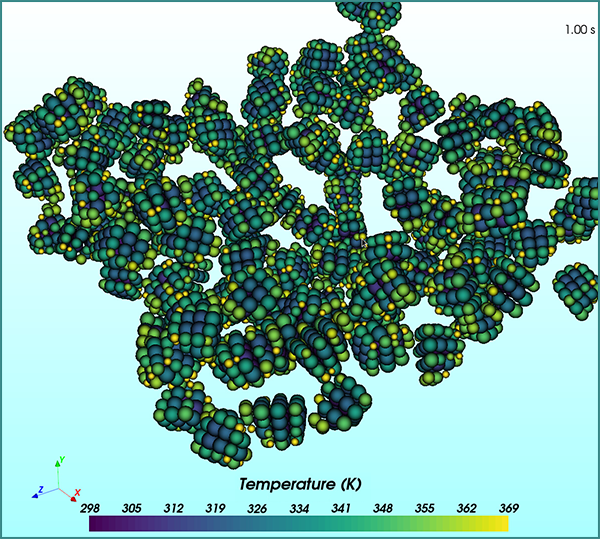

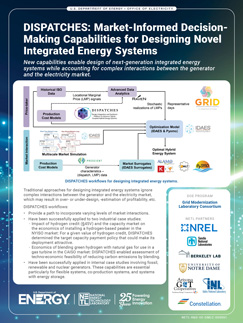

NETL’s Simulation-Based Engineering program guides a multidisciplinary approach comprising software development, computational power, data repositories, experimental facilities and unique partnerships to support research into timely and accurate solutions for energy and carbon management systems. Analysis and visualization tools are manipulated to gain scientific insights into complex, uncertain, high-dimensional and high-volume datasets. The information generated is then collected, processed and used to inform research that combines theory, computational modeling, advanced optimization, physical experiments and industrial input with a focus on the following three key technology areas: Advanced Process Simulation, Multiphase Flow Science and the Wafer-Scale Engine. Program and project information is presented in a dashboard below.