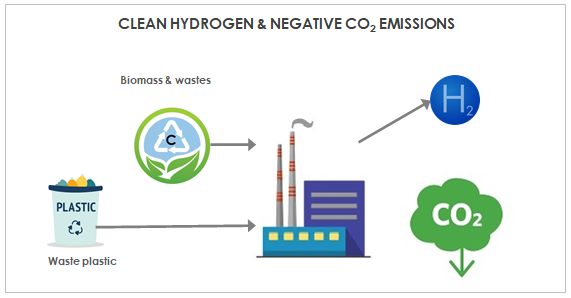

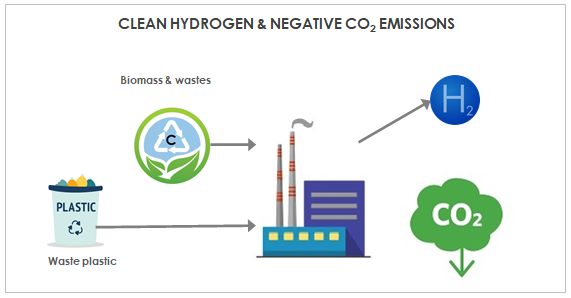

Clean Hydrogen & Negative CO2 Emissions focuses on designs and strategies for modular gasification-based systems enabling negative lifecycle emissions of greenhouse gases. Biomass can have an important role in reducing carbon intensity of solid fuel-based systems, as can application of advanced technologies integrating carbon capture. Likely approaches to be considered include co-utilization of biomass with wastes as gasification feedstocks, integrated or pre-combustion capture of CO2 especially facilitated by gasification, and innovative technological approaches or combinations of technologies enabling extensive greenhouse gas reductions of modular gasification systems.

Clean Hydrogen & Negative CO2 Emissions focuses on designs and strategies for modular gasification-based systems enabling negative lifecycle emissions of greenhouse gases. Biomass can have an important role in reducing carbon intensity of solid fuel-based systems, as can application of advanced technologies integrating carbon capture. Likely approaches to be considered include co-utilization of biomass with wastes as gasification feedstocks, integrated or pre-combustion capture of CO2 especially facilitated by gasification, and innovative technological approaches or combinations of technologies enabling extensive greenhouse gas reductions of modular gasification systems.

Philosophy

Interest in the concept of co-feeding biomass to fossil fueled plants including advanced gasification-based plants such as IGCC power plants, emerged from the idea that mixed feedstocks with biomass systems could become part of an early compliance strategy for carbon reduction, particularly across the large existing installed base of coal-based power plants. Recognizing that large biomass-alone power plants are constrained by issues of low biomass energy density, feedstock water content, feedstock collection and preparation, and seasonal/regional feedstock availability, waste-biomass systems could benefit from the stability of a multiple feedstock mix, adding tractable amounts of biomass as constrained by technical/performance requirements and biomass availability.

Co-feeding biomass can reduce the carbon intensity of power plants, but to achieve zero or negative lifecycle greenhouse gas emissions, some degree of carbon capture must be implemented. Gasification systems have the advantage considering that CO2 in typical syngas is much more concentrated and pressurized than the CO2 in the flue gas of combustion-based plants. Both concentration and elevated pressure aid in separating CO2 from the syngas. Also, innovative modular gasification and water gas shift reactors afford opportunities for in situ oxygen production and gas separations which can facilitate or reduce the costs of CO2 capture.

Strategy

Thermochemical co-conversion cycles consisting of 1) gasification-based electricity production with carbon capture and storage, and 2) long-chain hydrocarbon fuels production via gasification and the Fischer–Tropsch process (or alternatives) with carbon capture and storage, or both (polygeneration) have been strongly advocated as viable/accommodating process systems for a feasible commercialization strategy for carbon-negative energy. The NETL Gasification Program accords with this strategy with its recent efforts in modular gasification-based systems for production of clean hydrogen which can be utilized in decarbonized power generation, fuel synthesis, and more. R&D of these systems should continue towards demonstration of technical feasibility at commercial scale and reduction of investment risk, which have been identified by the R&D community as key research and policy needs in carbon negative energy systems development.

In the biomass gasification field, low-pressure moving bed or fixed bed gasifiers and fluidized bed gasifiers are commonly used, given their relative flexibility in handling varying feed streams and suitability to the sizes needed for typical applications. However, oxygen- or steam-blown high-pressure gasification of varied biomass and waste feed streams has been advocated as an important area of focus for R&D to improve system efficiency and costs, while simultaneously addressing waste disposal and environmental concerns. NETL has begun to make inroads into this area as it supports R&D of high-pressure modular gasifiers, high-pressure feeding of lower quality fuels including biomass/waste blends, lower cost air separation for modular systems, and better integration with carbon capture and storage. The R&D strategy is to continue pursuing gasifier technology for higher efficiency gasification of waste/biomass blends and reduction of those technology costs. This will strongly enable negative greenhouse gas emissions technology in gasification systems.

Projects

Clean Hydrogen from High-Volume Waste Materials and Biomass

The following projects concern technology development supporting production of net-zero carbon hydrogen from blended feedstocks that include biomass, waste coal, waste plastics, and municipal solid wastes, with carbon capture included in process systems:

Advancing Entrained-Flow Gasification of Waste Materials and Biomass for Hydrogen Production—This University of Utah project is studying gasification of blends of biomass and high-volume waste materials (in the form of various slurried mixtures of coal, biomass liquid, and waste plastic oil) to produce hydrogen and improve feedstock preparation and feeding to enhance gasifier performance and conversion. A 1-ton/day pressurized, oxygen-blown entrained-flow gasifier outfitted with a new flexible fuel gasifier burner based on proven hot oxygen burner technology is being utilized, which should help improve feeding flexibility, feed quality, and cost performance.

Fluidized Bed Gasification for Conversion of Biomass and Waste Materials to Renewable Hydrogen—A Gas Technology Institute (GTI)-led team is evaluating the chemical kinetics and gasification behavior of biomass and waste material feedstock blends, as well as a safe and reliable feeding mechanism for those blends into GTI's U-GAS® pilot-scale gasifier. This is to establish the basis for development of a 5–50 megawatt-scale hydrogen production plant using the U-GAS technology fed with the unusual combination of biomass, waste plastic, and municipal solid waste (MSW).

Hydrogen Production from High Volume Organic Construction and Demolition Wastes—The Energy and Environmental Research Center at the University of North Dakota will study gasification of construction and demolition debris-containing treated lumber to produce clean hydrogen, while addressing the challenge of simultaneously capturing/storing arsenic contained in this contaminated feedstock. Integrated system design for an oxygen-blown fluid-bed gasification system, including gasifier structure and operating conditions, unit materials, tar cracking, and gas filtration is in scope.

Performance Testing to Advance Modular, Moving-Bed Gasification for the Generation of Low-Cost, Clean Hydrogen from Biomass Mixed with Legacy Coal Waste, Waste Plastic, and/or Other Waste—Electric Power Research Institute Inc. (EPRI) is qualifying blended feedstocks of biomass mixed with legacy coal wastes, plastic wastes, and refuse-derived fuel (RDF) as feedstocks for moving-bed gasification for modular production of high hydrogen content raw syngas that can be shifted to produce clean hydrogen. In particular, the effects of the various fuels on syngas compositions, organic condensate production, ash characteristics, and impacts on gasifier operations are the focus of the project.

Hydrogen Production from Modular CO2 Assisted Oxy-Blown Gasification of Waste Blends— Auburn University is developing a novel process to produce H2 from blended feedstock wastes via CO2-assisted oxy-blown gasification. The process involves integration of CO2-assisted oxy-blown gasification with novel, modular technologies for syngas cleanup and conditioning, including RTI’s fixed-bed warm desulfurization process, trace contaminant removal process, and advanced fixed-bed water-gas shift (WGS).

Gasification of Blended Feedstocks Coupled with Carbon Capture and Sequestration to Achieve Net-Zero or Net-Negative Emissions H2—The National Renewable Energy Laboratory (NREL) is investigating the production of low-carbon H2 through four related core areas focused on Systems Analysis, Gasification Reactor Modeling, Real-Time Feedstock Characterization, and Gasification Experiments. Systems analysis comprises TEA, LCA, and resource analysis on gasification of blended carbonaceous resources (i.e., sustainable biomass, mixed plastics waste, coal waste) to produce a low-cost and low-carbon H2 product. Gasification mesoscale modeling produces high-fidelity particle-scale simulations of gasification, augmented with machine learning methods to produce fast-solving sub-grid models that account for feedstock-specific behavior in MFiX reactor simulations. Real time feedstock characterization work involves measurement of the chemical and physical attributes of mixed gasifier feedstocks in real-time to enable feed-forward control, ensure stable operation of the gasifier, and optimize H2 production. Gasification experiments are proposed for the NREL Single Particle Rector (SPR) and the NREL Research Gasifier (NRG).

Onsite NETL Research— Clean Hydrogen & Negative CO2 Emissions

NETL’s R&IC’s work includes analysis of gasification of alternative feedstocks and feedstock control for clean hydrogen production with sustainable CO2 emissions:

- Gasification of Waste Plastic to Enable a Circular Economy—NETL is exploring the gasification of alternative carbonaceous feedstocks, such as waste plastic, waste coal, and biomass to generate hydrogen with minimal CO2 emissions.

- Feedstock Control for Gasification— NETL is developing intelligent systems capable of controlling the blend of mixed plastic waste, biomass, MSW, and waste coal supplied to a modular gasification system for production of H2 with CCS. Actively controlling the blend of waste plastics and other materials fed to a gasifier will make its operation more stable and enable the optimization of its operation based on the feed stream composition.

Hydrogen Shot Fact Sheet:

Fact sheet about the U.S. Department of Energy's Hydrogen Shot, which seeks to reduce the cost of clean hydrogen by 80% to $1 per 1 kilogram in 1 decade.

Other key technologies within Gasification Systems include the following:

Clean Hydrogen & Negative CO2 Emissions focuses on designs and strategies for modular gasification-based systems enabling negative lifecycle emissions of greenhouse gases. Biomass can have an important role in reducing carbon intensity of solid fuel-based systems, as can application of advanced technologies integrating carbon capture. Likely approaches to be considered include co-utilization of biomass with wastes as gasification feedstocks, integrated or pre-combustion capture of CO2 especially facilitated by gasification, and innovative technological approaches or combinations of technologies enabling extensive greenhouse gas reductions of modular gasification systems.

Clean Hydrogen & Negative CO2 Emissions focuses on designs and strategies for modular gasification-based systems enabling negative lifecycle emissions of greenhouse gases. Biomass can have an important role in reducing carbon intensity of solid fuel-based systems, as can application of advanced technologies integrating carbon capture. Likely approaches to be considered include co-utilization of biomass with wastes as gasification feedstocks, integrated or pre-combustion capture of CO2 especially facilitated by gasification, and innovative technological approaches or combinations of technologies enabling extensive greenhouse gas reductions of modular gasification systems.