Energy Conversion Engineering

Advancing chemical and energy conversion technologies to efficiently produce power, fuels and chemicals.

NETL has a long history of developing energy conversion systems for producing power, fuels and chemicals critical to meeting America's growing energy needs and long-term energy security.

NETL's Energy Conversion Engineering (ECE) directorate conducts application-driven research to advance chemical and energy conversion technologies, helping to achieve more flexible, efficient and cost-effective processes and systems for U.S. industry.

ECE's approach enables best-in-class techno-economic assessment, life cycle assessment and computational scale-up. Our researchers use experimental testing and modeling tools to reduce the time, cost and technical risk of advancing new technologies. Expertise includes catalysts and electrolysis for fuel production, energy conversion and energy storage; catalytic and electro-magnetic-supported reactor technologies for process intensification; integration of energy components and systems to support grid resilience; design and application of cyber-physical systems to support scale-up and control of integrated energy systems; and fundamental applied combustion and experimental diagnostics.

Recent Publications

Energy Conversion Engineering

Advanced Systems Integration

NETL's Advanced Systems Integration research focuses on developing new methods to tackle today's challenges with integrating and controlling advanced systems for producing power, chemicals and fuels. Among the areas of focus are addressing dynamic control problems earlier in the development process for systems, including hybrid power generation systems; developing enabling technology for magnetohydrodynamics (MHD) used in topping cycles; developing sensors and controls to support gasification of mixed waste and fossil fuels; and investigating options for cost-effective, long-duration energy storage.

Our researchers develop and apply multiphysics simulation, advanced sensing, dynamic system simulation, cyber-physical systems and artificial intelligence to facilitate system integration with optimal flexible operation.

Reaction Engineering

NETL's Reaction Engineering research advances catalytic and electro-magnetic-supported reactor technologies for process intensification and electrifying chemical production processes. This includes using electromagnetic fields to transform low-value chemical feedstocks into high-value chemicals and energy for on-demand use.

Our researchers lead NETL's Center for Microwave Chemistry (CMC), which provides nationally recognized leadership in microwave-enhanced reaction systems and microwave-assisted fuel conversions for industrial processes. It is also expanding its world-class capabilities to design, build, test and analyze separation processes — such as critical mineral and material (CMM) recovery and oxygen separation — taking novel materials developed from lab-scale to pre-pilot-scale.

Thermal Sciences

NETL's Thermal Sciences research reduces the time, cost and technical risk of discovering and developing new advanced energy technologies by using experimental testing and modeling tools. We conduct scale-up research ranging from power to chemicals, moving technologies from concept development (Technology Readiness Level (TRL) 2/3) to pilot demonstration (TRL 5/6). Our expertise centers on three areas: multi-phase chemical reactor and process development, electrochemical physics and device engineering, and advanced combustion and heat transfer testing and simulation.

Key Physical and Virtual Facilities

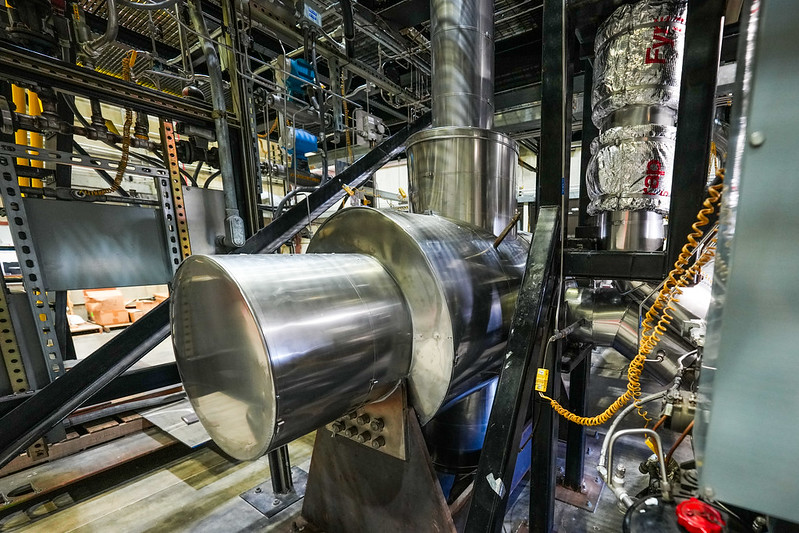

This facility provides technical capabilities in transformational energy conversion processes, including pressure gain combustion and sCO2 systems, allowing the advanced turbine blade cooling research needed to achieve high efficiencies, maximize output and lower costs.

This helps scientists develop more efficient conversion technologies, combustor designs and combustion systems.

The facility includes:

- Advanced water-cooled pressure-gain combustors

- sCO2 combustion and heat transfer test units

- Hydrogen/ammonia combustion R&D facilities

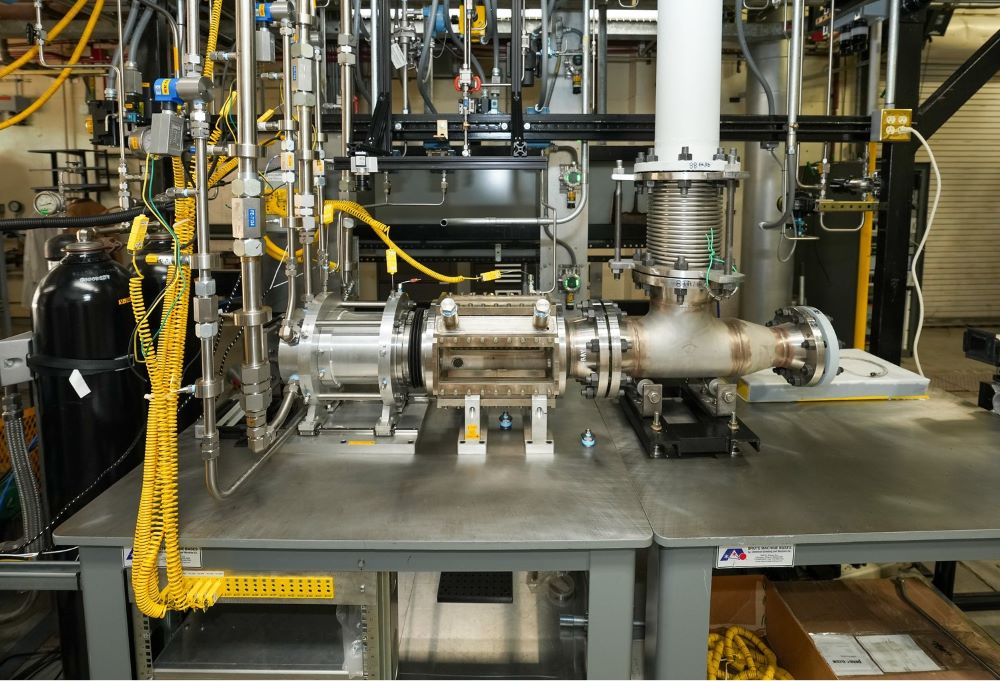

NETL’s Center for Microwave Chemistry achieves breakthroughs in reaction science that push the boundaries of explored research. The CMC helps scientists and engineers test chemical and fuel transformations using catalysts and electromagnetic methods, allowing them to explore new processes under various conditions that are not possible in standard labs.

The CMC features:

- Advanced microwave reactors

- High-speed imaging equipment

- Thermal imaging tools

- Online gas analysis capabilities

The Center makes it possible for researchers to conduct experiments with various fuel types, including coal, biomass and liquid hydrocarbon fuels, under a range of pressures, which can lead to fuel flexibility and enhanced energy security.

NETL is leading the development of an industry-supported test center for Direct Air Capture (DAC) technologies. Current work includes establishing baseline techno-economic and life cycle case studies; developing protocols for measurement, reporting and verification; and modeling material performance and degradation. These efforts enable consistent evaluation of DAC systems and provide a technical foundation for future field validation in collaboration with industry partners.

This facility supports research into high-efficiency power systems that achieve flexible turndown, thereby increasing reliability and resiliency of the modern grid. Specialties include advanced energy systems, including thermal and electrical integration and control, system operability and flexible generation response, with a focus on hybrid energy cycles and integrated energy and materials generation concepts.

NETL’s equipment helps organizations that want to improve their power systems' efficiency and reliability by developing and testing new technologies that increase energy generation and provide a platform for integrated energy system controls development.

Unique equipment includes:

- Solid state cells

- Gas turbines

- Internal combustion engines

NETL has specialized facilities for water separations and and critical mineral and material (CMM) recovery, including equipment to recover it from produced water and purify CMM via pre-treatment, treatment, membranes, sorbents, solvents and post-treatment processing.

This helps researchers investigate the recovery of CMM from liquids and solids by developing and testing technologies that improve the efficiency of recovery and reduce the cost of wastewater treatment, resulting in operational savings and increased mineral production.

CMM are prominently used for manufacturing and in advanced technologies from semiconductors to medical devices, making reliable and competitive domestic supplies vital to U.S. energy independence and national security.