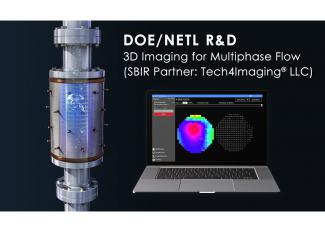

With support from the U.S. Department of Energy’s (DOE) National Energy Technology Laboratory (NETL), Ohio-based engineering and research firm Tech4Imaging LLC recently wrapped up two successful projects resulting in the development of a noninvasive, 3D imaging sensor technology for multiphase flows in advanced energy applications. This multi-year partnership highlighted the value of an industry-government collaboration that resulted in commercialization of the sensor technology while enriching the scientific knowledge base, advancing the education of several university students and creating jobs.

“The Department of Energy and NETL were critical to the success of these projects,” Tech4Imaging CEO and President Qussai Marashdeh said. “With guidance and financial support from NETL, we’ve gone from a design phase to building and testing our sensor systems in commercial-scale applications. Additionally, our company has grown from just one employee to 13.”

Tech4Imaging began business as a spin-off from The Ohio State University, and first received funding from DOE to develop this sensor technology in partnership with NETL’s in-house researchers. Subsequent funding came as Tech4Imaging applied for and was financially supported by NETL to conduct research through grants via the Small Business and Innovation Research (SBIR) program.

Marashdeh and his team developed the novel sensor technology to better understand the multiphase flows (i.e., the physical and chemical interactions of different phases of matter) found in fossil energy applications like coal gasifiers, coal-fired power plants, carbon capture systems, oil and gas operations, and many others. These systems are difficult to accurately measure through traditional point measurement, meaning that individual probes only report measurements at localized points of the overall process.

To overcome these measurement limitations, Tech4Imaging developed a new imaging technology called electrical capacitance volume tomography (ECVT), which enables noninvasive, real-time global measurements of multiphase flow systems. Furthermore, ECVT sensors can be used in the harsh environments often found in power plants and deep underground, capable of operating at temperatures of up to 900 degrees Celsius and pressures up to 35 megapascals.

In one practical example, the ECVT technology could have major impacts in the oil and gas industry by helping to realize more efficient drilling practices. Oil and gas companies don’t have reliably accurate methods of determining how much oil and gas (two separate phases within a given volume) an individual well produces, but an ECVT system could analyze this in real time. The technology is also capable of being integrated into geothermal applications, and a version of the system is currently installed in an international geothermal power plant as part of a commercial-scale demonstration.

NETL funding and management helped bring the ECVT technology from design to completion, and now the company is poised for success as they prepare to sell their sensor system to clients in a variety of fields.

“We’ve been thrilled with the progress of these projects,” Federal Project Manager Jessica Mullen said. “To see a partner evolve from the early project phases to become an independently successful and sustainable business really exemplifies NETL’s mission to produce technological solutions to America’s energy challenges.”

The ECVT technology can also be used to improve scientific understanding of multiphase flows by helping validate computational fluid dynamics code like NETL’s world-renowned, award-winning MFiX software suite. Validation through physical experimentation helps fine-tune this valuable software and allows for greatly accelerated design and development of advanced energy systems.

Beyond creating jobs, advancing the state of the art in sensor technology and adding to the scientific knowledge base, these projects also supported four Ph.D. students at The Ohio State University, led to 13 journal papers and resulted in several patents.

NETL is a U.S. Department of Energy national laboratory that produces technological solutions for America’s energy challenges. From developing creative innovations and efficient energy systems that make coal more competitive, to advancing technologies that enhance oil and natural gas extraction and transmission processes, NETL research is providing breakthroughs and discoveries that support domestic energy initiatives, stimulate a growing economy, and improve the health, safety, and security of all Americans. Highly skilled men and women at NETL’s sites in Albany, Oregon; Anchorage, Alaska; Houston, Texas; Morgantown, West Virginia; and Pittsburgh, Pennsylvania conduct a broad range of research activities that support DOE’s mission to advance the national, economic, and energy security of the United States.