Secure and reliable natural gas delivery is essential as the industry grows to meet an increasing portion of America’s energy needs. Natural gas accounted for nearly 32 percent of the electricity produced in the United States in 2017, and the U.S. Energy Information Administration expects that figure to rise to nearly 39 percent by 2050.

More than 300,000 miles of large transmission pipelines transport vast amounts of domestic natural gas nationwide. Every inch is susceptible to threats such as corrosion, the natural deterioration of metal materials caused by chemical reactions to the environment. Corrosion is one of the leading causes of pipeline leaks and ruptures, which threaten the safety of industry employees and the security of the nation’s energy supply.

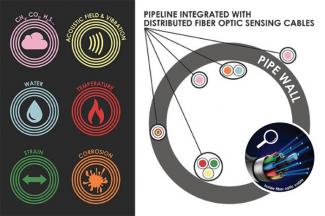

Researchers at NETL are working to address these concerns by developing advanced fiber-optic sensor systems that protect America’s pipelines by preventing leaks and failures before they occur. These systems will supersede conventional technologies, which are designed to detect pipeline leaks and failures that have already happened.

Preventing pipeline leaks and failures begins with monitoring conditions that are indicative of incipient failures, such as internal corrosion. Optical fibers – slightly thicker than a human hair and made of glass or plastic – are useful in monitoring corrosion within pipelines for many reasons, including their flexibility, size, resistance to harsh conditions, capability for monitoring along the entire length of the fiber (including spatial localization of measured parameters), and compatibility with data communication systems.

NETL researchers have developed optical fibers coated with corrosion proxy materials that deteriorate as the pipeline corrodes. When placed along a pipeline, laser light transmitted through the optical fiber produces backscattered light that shows imperfections in the thin corrosion proxy film. Those imperfections reflect conditions that are conducive to the onset of corrosion along the pipeline before failures occur, pinpointing the exact location for pipeline operators.

Researchers have also developed a novel fiber-optic sensor that can detect and characterize water condensation within the pipeline. The liquid water absorbs corrosive species within the gas stream, facilitating corrosion inside the pipeline. NETL’s innovative sensor technology directs laser light through an optical fiber placed within the pipeline to produce an optical spectrum, or wavelength, that is then analyzed using on a specific scientific formula to detect the size and location of water droplets. By identifying the onset of water condensation, the tendency for pipeline corrosion to occur locally can be identified and mitigated.

NETL researchers plan to expand the water-detection technology by incorporating additional fiber-optic sensing capabilities – such as dissolution of corrosive gases, fluctuation in temperature and pressure changes – that aid corrosion monitoring. These multi-functional sensors would be incorporated into fiber-optic sensing networks that provide continuous real-time corrosion monitoring information to pipeline operators.

“This research program is part of a suite of complementary sensing and materials technologies that are being developed simultaneously to impact risks and resiliency across the energy infrastructure. Our goal is to optimize sensor and protection systems to prevent failures and leaks before they occur, minimizing the economic and social costs,” said Paul R. Ohodnicki, Jr., Ph.D., of NETL’s Functional Materials Team.

“Ultimately, we envision an ‘intelligent pipeline’ enabled by advanced technologies, including embedded sensors, protective coatings and liners, and geospatial data analytics. We are also taking a similar approach in the development of sensing networks for other energy infrastructure monitoring applicants, including power plants, wellbores, carbon storage sites, and electrical grid assets such as power transformers.”

NETL’s work to develop enhanced sensing technology will help the natural gas industry continue to thrive in the coming decades. By reducing risk and enhancing safety, these technologies encourage valuable investments in home-grown energy that stimulate the economy and create jobs as they boost the nation’s energy dominance.

To learn more about the Lab’s Sensors and Controls Program, click here.

Contact: