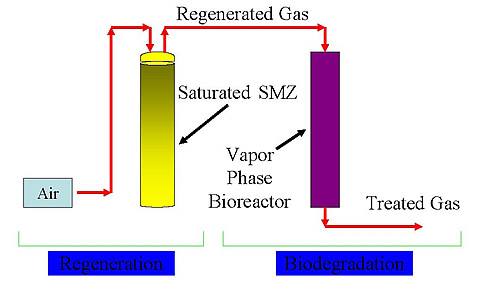

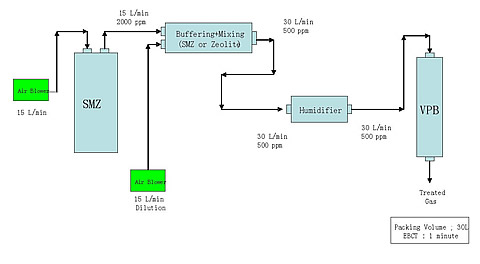

SMZ is an innovative filtration/sorption medium that has been shown to remove contaminants such as benzene, toluene, ethylbenzene, and xylenes (BTEX) from produced waters. Cost-effective operation of an SMZ requires a method of regenerating the SMZ onsite. The air-sparging method, developed as part of the joint University of Texas and LANL project, can regenerate SMZ. The process generates a moist air stream contaminated with relatively low concentrations of volatile organic compounds (VOCs), including BTEX, that must be removed. These VOCs are biodegradable and present in small concentrations. The VPB is used to eliminate the pollutants created during the SMZ regeneration.

Project Results

The pilot system has been built, and pilot testing originally was to have started in New Mexico in May 2005. However, testing was deferred pending placement of the pilot SMZ/VPB system at Burlington Industries’ McGrath saltwater disposal facility near Farmington, NM. The test was delayed until August 2005 in order for site preparations to be completed at the McGrath facility. The pilot system was moved in during August 2005, and testing was performed for 4 weeks. Extensive data were collected on the linked SMZ/VPB system performance. Effects of field water quality, variable flow rates, and precipitation of metal oxides in the flow system were observed, and the system was adjusted to compensate.

The change in schedule will push back the report date of the project as data analysis and reports are in progress at this time. This work will be done as a no-cost extension, as reduced costs were incurred during the waiting period for the facility to be ready.

At this time no regulatory issues have arisen, due to the permitted status of the McGrath facility.

Benefits

Reuse of produced water will greatly impact production costs in the oil and gas industry. In the United States, the average production of produced water is 10 barrels of water for each barrel of oil. The SMZ/VPB technology is designed to allow onsite treatment of produced water as an alternative to disposal. The process will reduce production costs and provide beneficial reuse of the water.

Project Summary

From work accomplished under the University of Texas contract DE-FC26-02NT15461, LANL was to provide in the final report cost data from a survey of producers with respect to treatment and disposal of produced water. This ensures an accurate basis for estimating the feasibility of the treatment technology for end users. LANL also is working with UT, New Mexico Tech, and Burlington on the final design parameters and operating variables for the field-scale column test and participating in the field demonstration.

The first main tasks of the project have been completed: the cost data survey, an economic and engineering assessment, and a feasibility evaluation and engineering cost estimate. Phase 4 and Phase 5 reports covering these tasks remain to be finished, as they await completion of field pilot testing.

Under the second group of tasks, LANL provided support for field pilot testing and larger-scale, long-term testing at McGrath. The water from the McGrath facility is the same water that ultimately would be sent to Public Service Company of New Mexico (PNM) for use as power plant cooling tower water make-up.

The second group of tasks is split into two time periods:

- Months 1-12: LANL provides input on material requirements with respect to the reverse osmosis membranes, PNM's requirements, and other design requirements that require interface with other system components and with the PNM site processes. If other sites are involved, then LANL coordinates with those sites to facilitate the work.

- Months 13-27: LANL continues as the contact point between PNM or any other field sites and the project. LANL also provides safety training for students as needed and field supervision of portions of the set-up and start-up of the field system.

Moving field testing to the McGrath facility allows researchers to perform the pilot test and the larger-scale, long-term testing at the same facility, leveraging the cost share from Burlington Industries and using the same source water for both projects. Because the water from the McGrath facility is the same water that will be sent to the PNM Four Corners power plant, that should allow an efficient move for the technology to the PNM location when the utility has produced water onsite.