The NETL-Regional University Alliance (NETL-RUA) Fuel Cell Project performs fundamental SOFC technology evaluation, enhances existing SOFC technology, and develops advanced SOFC concepts in support of the SECA program. Research projects are designed to meet critical technology development needs that can be uniquely addressed by NETL-RUA and are broadly focused on investigation of the degradation processes of anode/electrolyte/cathode (AEC) components and engineering cathode materials and microstructures to enhance performance. The research approach for each component task is targeted to address SECA program technology development goals, especially with regard to reducing stack costs, increasing cell efficiency, and increasing stack longevity. The ultimate goal of these research and development efforts is to transfer technology that facilitates commercial acceptance of SOFC technology.

In FY14, the project will investigate the following tasks that directly addresses programmatically identified research priorities:

Task 2 Cell and Stack Degradation: Investigation of degradation modes exhibited by the anode/electrolyte/cathode (AEC), development of computational models describing the associated degradation rates, and generation of a modeling tool predicting long-term AEC degradation response.

Task 3 Electrode Engineering: Generation of novel cathode materials/microstructures and implementation of the improved cathode technology to enhance performance.

Task 5: System Level Economic and Process Models: Development of a facility to test 30 kWe stacks and systems.

Presentations_plp

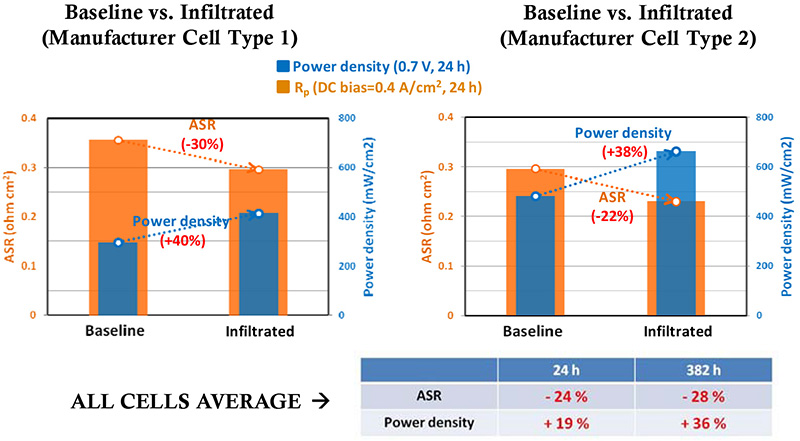

- Improved Performance Stability of Solid Oxide Fuel Cells Achieved through Sr-Fe-O Infiltration of LSM/YSZ Cathode (2017)

Poster by Yueying Fan, U.S. Department of Energy, National Energy Technology Laboratory, at the 2017 SOFC Project Review Meeting.

- Prediction of Performance Degradation Due to Grain Coarsening Effects in Solid Oxide Fuel Cells (2017)

Poster by Jerry Hunter Mason, U.S. Department of Energy, National Energy Technology Laboratory, at the 2017 SOFC Project Review Meeting.

- Classifying Heterogeneity in SOFC Electrodes (2017)

Poster by William K. Epting, U.S. Department of Energy, National Energy Technology Laboratory, at the 2017 SOFC Project Review Meeting.

- Phase Field Modeling on Initial Microstructure Effect on Grain Coarsening and Concomitant Property Degradations in SOFC Electrodes (2017)

Poster by Yinkai Lei, U.S. Department of Energy, National Energy Technology Laboratory, at the 2017 SOFC Project Review Meeting.

- Bayesian Calibration of Models of SOFC Electrode Materials (2017)

Poster by Giuseppe Brunello, U.S. Department of Energy, National Energy Technology Laboratory, at the 2017 SOFC Project Review Meeting.

- Nano-Catalyst Infiltration by Bio-Surfactant Modification of Anode Supported SOFC Electrodes (2017)

Poster by Ozcan Ozmen, U.S. Department of Energy, National Energy Technology Laboratory and West Virginia University, at the 2017 SOFC Project Review Meeting.

- Quantitative Mesoscale Analysis of SOFC Electrodes Based on 3D Reconstructions Using Xe-Plasma Focused Ion Beam (pFIB) Coupled with SEM (2017)

Poster by Rubayyat Mahbub, U.S. Department of Energy, National Energy Technology Laboratory, at the 2017 SOFC Project Review Meeting.

- High Performance Computation of Local Electrochemistry via TPB and MIEC Pathways in SOFCs based on Morphology-Preserving Microstructural Meshes (2017)

Poster by Tim (Yu-Ting) Hsu, U.S. Department of Energy, National Energy Technology Laboratory, at the 2017 SOFC Project Review Meeting.

- Noninvasive Optical Sensor Development for Real-Time Solid Oxide Fuel Cell Monitoring Applications (2017)

Poster by Youngseok Jee, U.S. Department of Energy, National Energy Technology Laboratory, at the 2017 SOFC Project Review Meeting.

- Density-Functional Study of the La2Zr2O7 Low-Index Faces (2017)

Poster by Yves Mantz, U.S. Department of Energy, National Energy Technology Laboratory, at the 2017 SOFC Project Review Meeting.

- Multi-physics Modeling of Solid Oxide Fuel Cells with Parallel Oxygen Reduction Reaction Pathways (2017)

Poster by Tao Yang, U.S. Department of Energy, National Energy Technology Laboratory, at the 2017 SOFC Project Review Meeting.

- NETL R&D: SOFC Materials Development and Degradation Modeling

Presented by Greg Hackett, National Energy Technology Laboratory, at the 2017 SOFC Project Review Meeting.

- System Analysis of Fuel Cell Plant Configurations

Presented by Greg Hackett, National Energy Technology Laboratory, at the 2017 SOFC Project Review Meeting.

- National Energy Technology Laboratory R&D: SOFC Materials Development and Degradation Modeling (2016)

Presented by Gregory A. Hackett, U.S. Department of Energy, National Energy Technology Laboratory, at the 2016 SOFC Workshop.

Principal Investigator

Greg Hackett

gregory.hackett@netl.doe.gov

Project Benefits

Task 2 focuses on the investigation of degradation modes exhibited by the anode, electrolyte, and cathode (AEC), the development of computational models describing the degradation rates, and generation of a modeling tool predicting long term AEC degradation response. Improved cell/stack life and performance will reduce operating cost and increase efficiency, resulting in reduction in the cost of electricity and reduction of CO2 emissions from the entire platform. Specifically, this project will conduct cell tests, utilize conventional electrochemical techniques to measure performance, and employ advanced spectroscopic techniques in post-test analysis. Task 3 focuses on the development and performance evaluation of electrode materials and structure that improve peak cell power output while maintaining cost and durability metrics. Improved cell/stack life and performance will reduce operating cost and increase efficiency, resulting in reduction in the cost of electricity and reduction of CO2 emissions from the entire platform. Specifically, this project will identify and characterize manufacturing processes, select and evaluate candidate materials, conduct lab-scale performance and stability tests, and demonstrate the preferred process and materials in short-stack testing. Task 5 focuses on estimating component and system costs and the economic benefits of technical innovations. Improved cell/stack life and performance will reduce operating cost and increase efficiency, resulting in reduction in the cost of electricity and reduction of CO2 emissions from the entire platform. Specifically, this project will estimate the economic benefits associated with the fundamental and applied research completed in other program-sponsored R&D projects.

Project ID

FWP-2012.03.04

https://www.netl.doe.gov/research/on-site-research