U.S. Department of Energy (DOE) researchers across the nation are accelerating efforts to solve challenging production, transportation and storage issues to put hydrogen (H2) to work as a low-carbon fuel option for a range of critical energy applications. NETL is a key part of that overall effort with work to advance surveillance and monitoring technologies for underground H2 storage facilities that ensure maximum safety.

Safe underground H2 storage calls for technologies that effectively monitor facilities to make sure the gas remains safely stored in underground resources until it is needed to power more of the nation’s critical transportation, electricity generation, and manufacturing applications.

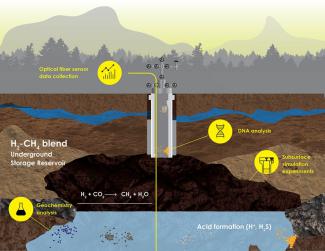

According to Ruishu Wright of NETL’s functional materials team, a range of sensors and wellbore monitoring tools have been used in geological carbon dioxide (CO2) sequestration, the oil and gas industry and other relevant underground storage industry applications. At NETL, a team of experts are helping develop cost-effective approaches for monitoring H2 underground storage facilities over broad areas – capabilities necessary because of the greater mobility and buoyancy of H2 gas plumes.

The work is part of NETL’s participation in a multi-national laboratory effort known as Subsurface Hydrogen Assessment, Storage and Technology Acceleration (SHASTA). The Department of Energy’s (DOE) Office of Fossil Energy and Carbon Management established SHASTA in 2021 to explore H2 storage opportunities in geologic reservoirs. In addition to NETL, DOE labs participating in SHASTA include the Pacific Northwest National Laboratory, Lawrence Livermore National Laboratory, and Sandia National Laboratories.

“Surveillance and monitoring are important for evaluating and managing operational risks of underground hydrogen storage,” Wright said. “Therefore, real-time monitoring is needed to assure storage infrastructure integrity and to detect early signs of gas leakage.”

Because industry has used hydrogen in a range of applications for decades, there are many commercial hydrogen sensors in operation, including catalytic combustion sensors, electrochemical sensors, thermo-conductivity sensors, resistive sensors, acoustic leak sensors, and optical based sensors.

“The problem is that existing sensor technologies are mostly point or standoff hydrogen sensors,” Wright said. “There is a real need for wide-area and long-distance monitoring for hydrogen leak detection in large-scale storage facilities. In addition, the subsurface conditions in some underground storage facilities can be challenging because of higher pressures and temperatures that are not encountered in typical sensor-operating conditions.”

That means researchers are at work evaluating emerging sensor technologies such as optical fiber sensors and passive wireless sensors that are safer in flammable gas mixtures compared to electrical-based sensors.

Researchers are also racing to meet the need for technologies that can monitor groundwater quality to identify geochemical changes that may be required to prevent groundwater contamination. Some geochemical changes can potentially lead to wellbore failures, which are also need real-time monitoring.

Another area of focus in H2 storage surveillance and monitoring is induced seismic events: minor quakes and tremors caused by activities like geothermal energy extraction, mining dam building, construction and hydraulic fracturing that alters the stresses and strains on Earth’s crust.

Experience with induced seismic events at underground storage facilities is very limited. But there is significant experience in seismic monitoring and risk management in the oil and natural gas, wastewater disposal, and CO2 sequestration areas that can be applied to seismically problematic gas storage operations. SHASTA efforts are concentrating on making sure all the most useful and effective technologies are brought to bear on the surveillance and monitoring needs of this emerging industry.

NETL drives innovation and delivers technological solutions for an environmentally sustainable and prosperous energy future. By using its world-class talent and research facilities, NETL is ensuring affordable, abundant and reliable energy that drives a robust economy and national security, while developing technologies to manage carbon across the full life cycle, enabling environmental sustainability for all Americans.