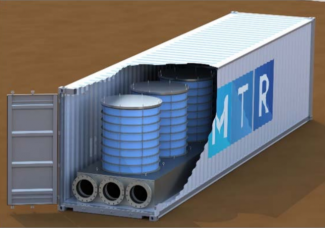

The image above shows a modular container unit with Polaris membrane stacks. The CEMEX project will have multiple containers. Credit: Image provided by Membrane Technology & Research Inc.

NETL’s industry partners are evaluating the use of a transformational membrane technology to capture greenhouse gas produced during the manufacturing of cement and lower the environmental footprint for this important building and construction material.

“The project being developed with our industrial partners at the CEMEX Balcones facility in New Braunfels, Texas, is generating an initial engineering design and constructability review to determine if the application of an advanced industrial membrane capture technology at a cement plant is feasible,” said NETL’s Carl Laird, federal project manager.

Cement mixed with sand and gravel produces concrete, an affordable and reliable product for construction and the most widely used man-made material in existence. “However, the production of cement in kilns also generates large volumes of carbon dioxide (CO2),” said Laird, a chemical engineer who joined NETL in June 2020 after a 15-year career in the private sector where he established himself as a subject matter expert in flue gas treatment in the utility, industrial and cement markets.

CO2 capture from industrial facilities, including cement plants, petroleum refineries and chemical production plants, is critical to battle the climate crisis and achieve the goals of the Biden-Harris Administration, which call for net-zero carbon emissions in the power sector by 2035 and the broader economy by 2050.

The CEMEX Balcones operation produces about 2.2 million tonnes of cement annually, with flue gas from its kilns generating substantial carbon emissions.

The 18-month CEMEX project, scheduled for completion on March 31, 2022, will estimate the cost and performance of installing a full-scale (1 million tonnes of CO2 captured per year) Polaris membrane CO2 capture system at the New Braunfels plant. Other project deliverables include preliminary engineering drawings, a construction schedule and construction estimates.

The U.S. Department of Energy (DOE) awarded nearly $1.5 million in project funds, with project partner Membrane Technology & Research Inc. (MTR) contributing $373,329. CEMEX has provided plant-specific information for the study.

“This work is critical to advance to the next project stage — development of a full-scale engineering design to implement a first-of-its-kind CO2 membrane technology at a cement plant,” said Laird, a Penn State University graduate who co-authored three patents to reduce acid gas emissions while leading a product development team before joining NETL.

“It also bridges the gap between full-scale engineering design and previous work, completed with NETL support, oversight and expertise over the last decade, that had advanced the technology from laboratory testing to the current 10-MWe pilot scale,” Laird said.

The project is one of multiple efforts included in NETL’s Carbon Capture Portfolio. The Lab is advancing a full complement of technology solutions aimed at step-change improvements in the economics, efficiency and reliability of carbon capture that are suitable to the unique environments of post-combustion and pre-combustion applications and direct air capture.

Membranes consist of thin layers of either polymer (organic, plastic) or inorganic (metal, ceramic) materials that are permeable to the molecules they are meant to capture, such as water, CO2 or oxygen. The Lab’s areas of focus include developing low-cost, durable membranes with improved permeability and selectivity, thermal and physical stability, and tolerance to contaminants.

In prior work with DOE, MTR advanced membrane CO2 capture technology for fossil-energy power plants through small engineering-scale testing and studies. Sensitivity studies indicated that the membrane capture approach is even more attractive when the flue gas has higher CO2 content, such as that found in cement plants and other industrial sources.

Previous testing at a test system at the Technology Centre Mongstad in Norway provided important results from a single container of MTR membrane stacks to capture carbon. CEMEX would use multiple membrane stacks.

The CEMEX project also would capture and generate high-purity CO2 for permanent storage in deep subsurface formations or for application in developing technologies, such as using the gas as a feedstock to produce high-value chemicals or as supercritical CO2 to operate turbomachinery. Those applications could provide revenue to offset the costs of carbon capture.

A next step in the CEMEX project is to obtain additional funds to complete a full front-end engineering and design study, which will include more detailed engineering work, as well as Class 3 or better cost estimates to ensure accuracy.

NETL is a U.S. Department of Energy national laboratory that drives innovation and delivers technological solutions for an environmentally sustainable and prosperous energy future. By leveraging its world-class talent and research facilities, NETL is ensuring affordable, abundant and reliable energy that drives a robust economy and national security, while developing technologies to manage carbon across the full life cycle, enabling environmental sustainability for all Americans.