Unconsolidated or friable sand formations pose unique completion problems related to near-wellbore damage to the formation, resulting in reduced production and increased costs in wellbore cleanout and recompletion. Sand production is both a safety issue and expensive to prevent. The objective of the field demonstration was to show industry that CLC methods offer a more cost-effective method to produce oil and gas from friable reservoirs and prevent excess sand production.

The concept of a cavity completion is to increase the effective wellbore radius and reduce skin by removing existing near-wellbore damage. A small volume of sand removed can reduce a high positive skin factor dramatically. High positive skin factors that are normally associated with cased and perforated completions can be reduced dramatically with a properly designed CLC. In several CLCs where reliable information is available from the field, low skin factors have been indicated. The promise of CLC technology is to be able to initiate the well with a low skin factor or to recomplete it and realize increased productivity.

Project Results

The project conducted laboratory and field tests of a model to predict the performance of cavity-like completions (CLCs). Texas A&M's Global Petroleum Research Institute, in a joint venture with a group of oil and gas companies, documented six field involving CLCs.

A test of the CLC method in Mustang Island, TX, gas wells resulted in incremental cash of $525,000/month.

Benefits

CLC offers a new technique to complete wells in friable and unconsolidated sands. A successfully designed CLC provides significant increases in well performance at lower costs than alternative completion techniques.

Project Summary

The project modeled four different friable sand scenarios:

- Weakly cemented sediments.

- Thin pay zones overlain by competent cap rock.

- Multiple thin layers.

- Exposure to wear from shutdowns and start-ups.

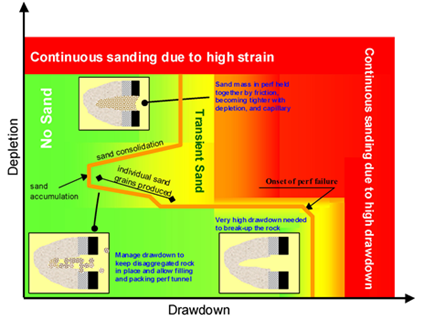

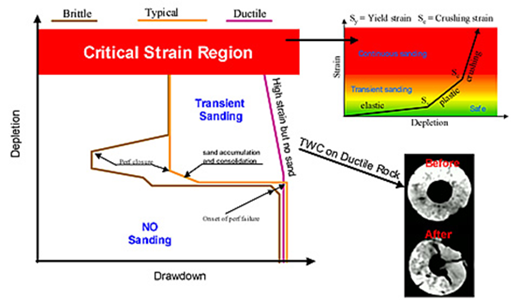

Factors influencing sand stability included depth (effective stress), particle size distribution, arching, rapid changes in pressure, and loss of capillary cohesion.

Researchers designed a CLC method that developed a stable cavity near the wellbore into which the oil could flow. This entailed flowing the well hard to get the loose sand out, then producing the well at a slightly lower rate.

To develop and sustain a stable cavity, it is essential for the formation to have some degree of cementation, which allows for near-wellbore sand to be produced while maintaining a stable sand face. A controlled clean-up strategy must be established to assure a stable sand face.

Understanding cavity growth and stabilization requires consideration of the combined effects of fluid flow, changing in-situ stresses, material failure and material deformation. Modeling the possible scenarios-and factoring in these difficulties-provides a "best practices" method for CLCs.

In addition to modeling the completion methods, an economic model for CLC was prepared. The CLC procedure can be repeated on individual wells as needed. Analysis was completed for carbonate wellbores as well as friable sands.

A series of case studies of the CLC method was conducted in the Gulf of Mexico. An overview of these wells was used to design a field demonstration on Mustang Island, TX. In this successful cavity completion on the Gulf of Mexico shelf, the sand-free flow rate was increased from 1 million standard cubic feet per day (MMscf/day) to 4.5 MMscf/day of gas after 10 barrels of sand was produced. An acoustic sand detector was deployed to continuously monitor sanding. Incremental revenue from the CLC procedure was $12,800 per day, minus the cost of $5,700 per day, for a profit of $7,000. The Mustang Island well continued to flow at the increased rates for six months before watering out. The post-cavitation profit was $3.15 million.