An NETL-managed project is making impressive progress toward developing a state-of-the-art facility to produce a domestic supply of valuable mixed rare earth compounds from coal and coal byproducts.

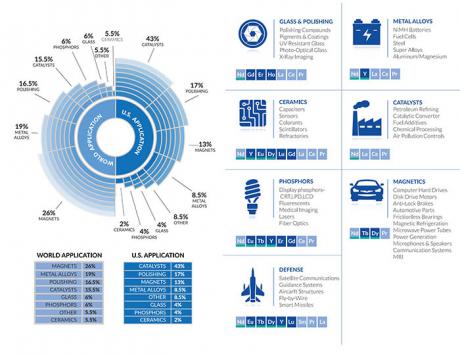

Fifteen lanthanide elements within the periodic table, including scandium and yttrium, are referred to as rare earth elements (REEs). They are essential components in many modern technologies — including cell phones, medical devices and national defense systems — yet challenging to extract, with China providing the bulk of the world’s supply.

NETL’s McMahan Gray, a physical scientist in Pittsburgh, has been named a recipient of a 2018 Innovation Award from The Pittsburgh Business Times. The honor, to be bestowed at a special ceremony later this year, recognizes extraordinary advances that challenge conventional thinking

Gray is being honored for his work developing an effective, efficient and environmentally friendly technology that can remove carbon dioxide from air, remove lead from water, and recover rare earth elements (REEs) from water and waste streams.

Rare earth elements (REEs) – an integral component of high-technology products from smart phones and lasers to computer hard drives, medical devices and national defense systems – are not that rare, they just appear in miniscule concentrations in a variety of sources, including water. NETL researchers have developed a way to effectively filter water from oil and natural gas well flowbacks, industrial waste streams, acid mine drainage and even municipal drinking water to recover valuable REEs.

Acid mine drainage (AMD) – a waste byproduct that must be treated – is an inevitable trade-off for the affordable, abundant and reliable power derived from coal mining operations. But AMD now offers potential economic opportunities, thanks to emerging technology being developed in collaboration with NETL to extract rare earth elements (REEs).

In the middle of the 20th century, the United States became a leading global supplier of rare earth elements (REEs). These valuable materials were used extensively in the manufacture of innovative technologies like color televisions and other high-tech devices of the time. However, U.S. dominance in the rare earth market began to slip near the turn of the 21st century, and now China exports almost all the world’s rare earth elements.

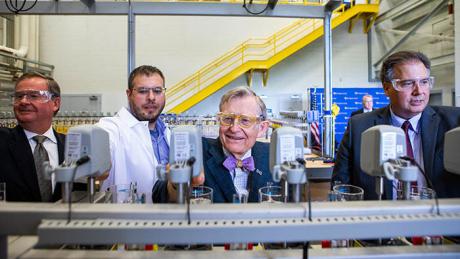

An innovative bench-scale facility established at West Virginia University (WVU) in collaboration with NETL will demonstrate the feasibility of extracting rare earth elements (REEs) from acid coal mine drainage (AMD) to develop a domestic supply of REEs – an effort that will enhance America’s economic growth and national security.

Four rare earth elements (REEs) recovery projects managed by the U.S. Department of Energy’s (DOE) Office of Fossil Energy and the National Energy Technology Laboratory (NETL) have made significant progress in the development of a domestic supply of REEs from coal and coal by-products by successfully producing REE concentrates.

The U.S. Department of Energy’s (DOE) National Energy Technology Laboratory (NETL) has found high rare earth element (REE) concentrations in coal samples taken from the Illinois, Northern Appalachian, Central Appalachian, Rocky Mountain Coal Basins, and the Pennsylvania Anthracite region. These highly concentrated samples are greater than 300 parts per million (ppm).